Help with strange under extruding on layer change

-

I need some help please, so I have built a 3d printer, cartesian.

It's all working but for one issue, whenever the extruder retracts or starts a new layer, it doesn't seem to extrude right away leaving missing lines in my print and on the first layers.

I've calibrated e steps several times and also checked retract settings which are fine.

I have no slipping in the gears.

Where things get a bit stranger is that, my e steps are calibrated perfectly but it over extruders with 100% flow rate (cura) so have to set flow to 88%...howrver even at a 100% flow rate the slow extrusion at the stsrt of a layer is still presant.

I've tested 2 brand new extruders and both same issue )))

-

@craigrobbo-0 said in Help with strange under extruding on layer change:

Where things get a bit stranger is that, my e steps are calibrated perfectly but it over extruders with 100% flow rate (cura) so have to set flow to 88%

That isn't uncommon. Usually it has to do with the diameter of the filament and the nature of the filament itself. Just part of fine tuning.

@craigrobbo-0 said in Help with strange under extruding on layer change:

and also checked retract settings which are fine.

What are your retraction settings?

Is this a direct drive or bowden extruder?

Do you have retraction enabled on layer change in your slicer? I believe the default in cura is to no retract on layer change or travels. This can lead to under extrusion because the plastic in the nozzle may ooze out and it takes a while to build up pressure again.

At any rate, we'd need to see more specifics of your setup to be able to help much more. Please share your config.g and perhaps a sliced gcode file so we can see your slicer settings.

-

Thank you, sorry for late reply I didn't appear to get a notification for the reply?

So the gcode I'm confident is fine as the same gcode works fine on my other printer without this issue.

I'll upload my config.g later.

It seems someone suggested it's a pressure advance issue but after playing with this for a while, it made zero difference to this particular issue.

The extruder is a biqu h2, I tried some "extra prime" settings but this helped in some places but then left lots of zits in other places...

-

Is there perhaps a problem with extruder assembly?

https://www.biqu.equipment/products/biqu-h2-v2-0-extruder@craigrobbo-0 said in Help with strange under extruding on layer change:

So the gcode I'm confident is fine as the same gcode works fine on my other printer without this issue.

Is the other printer the same as this one?

-

@craigrobbo-0 Make sure the gear on the stepper motor is tight. Pressure advance, M572, if the setting is too high, it makes my infill not reach the perimeters..

-

@phaedrux said in Help with strange under extruding on layer change:

Is there perhaps a problem with extruder assembly?

https://www.biqu.equipment/products/biqu-h2-v2-0-extruder@craigrobbo-0 said in Help with strange under extruding on layer change:

So the gcode I'm confident is fine as the same gcode works fine on my other printer without this issue.

Is the other printer the same as this one?

Again sorry for late reply, I'm unsure why I'm not getting notifications?

Any way, no 2 different printers but both are direct drive.

So I have 2 extruders (bother biqu h2) and I stripped them down fully, made sure nothing was binding and reassembled, all looks spot on.

Becasue the under extrusion is so consistent I wouldn't have thought it to be the extruder.

Last night I made some more changes to my settings, reducing retract and turned off retract on layer change, but still looks just as bad unfortunately

-

@stephen6309 said in Help with strange under extruding on layer change:

@craigrobbo-0 Make sure the gear on the stepper motor is tight. Pressure advance, M572, if the setting is too high, it makes my infill not reach the perimeters..

I've rebuilt them and they're 100% good

-

So I decided to turn off retraction and the problem still persists... Pulling my hair out on this!

-

@phaedrux said in Help with strange under extruding on layer change:

At any rate, we'd need to see more specifics of your setup to be able to help much more. Please share your config.g and perhaps a sliced gcode file so we can see your slicer settings.

-

@phaedrux said in Help with strange under extruding on layer change:

@phaedrux said in Help with strange under extruding on layer change:

At any rate, we'd need to see more specifics of your setup to be able to help much more. Please share your config.g and perhaps a sliced gcode file so we can see your slicer settings.

Alright so here we go:

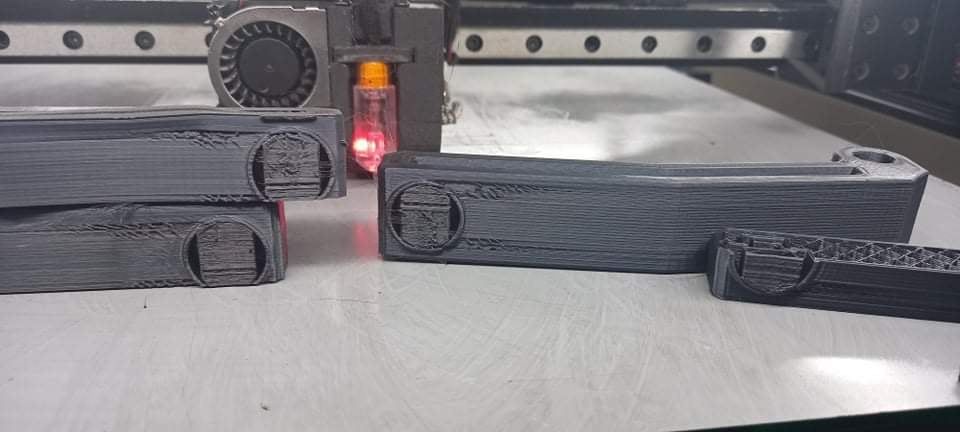

I am also uploading some photos of just a few tests of some of my settings changed

code_text ; Configuration file for Duet WiFi (firmware version 3) ; Made by Craig Robinson and tweaked by Marko Klemencic aka MaracMB ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"CraigsMachine" ; set printer name ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet M575 P1 S1 B57600 ; enable connection for PanelDue ; Drives M569 P0 S0 ; physical drive 0 goes backwards X is drive 0 M569 P1 S0 ; physical drive 1 goes forwards U is drive 1 M569 P2 S0 ; physical drive 2 goes backwards Y is drive 2 M569 P3 S1 ; physical drive 3 goes forwards E0 is drive 3 M569 P4 S1 ; physical drive 4 goes forwards E1 is drive 4 M569 P7 S1 ; physical drive 7 goes forwards Z1 is drive 5 M569 P8 S1 ; physical drive 8 goes forwards Z2 is drive 6 M569 P9 S1 ; physical drive 9 goes forwards Z3 is drive 7 M569 P10 S1 ; physical drive 10 goes forwards Z4 is drive 8 M584 X0 Y2 U1 Z5:6:7:8 E3:4 ; four Z motors connected to driver outputs 5,6,7 and 8 M350 X16 Y16 Z16 E16:16 U16 I1 ; configure microstepping with interpolation M92 X80 Y80.00 Z1600 E981:981 U80 ; set steps per mm 981 for corect steps 932 for default(E15090:15090 for 256 microsteps) M566 X1000 Y1000 Z10 E1000:1000 U200 ; set maximum instantaneous speed changes (mm/min) (tested 500 to 5000) M203 X20000 Y20000 Z500 E20000:20000 U20000 ; set maximum speeds (mm/min) (tested from 1000 to 20000) M201 X1000 Y1000 Z500 E1000:1000 U1000 ; set accelerations (mm/s^2) (tested 100 to 2000) M906 X950 Y950 Z950 E800:800 U950 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Pressure advance ;tested 0.01 upto 0.1 ;M572 D0 S0.1 ; Axis Limits M208 X-230 Y-230 Z0 U-175 S1 ; set axis minima M208 X175 Y215 Z385 U225 S0 ; set axis maxima ; Endstops M574 X1 S1 P"zstop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop M574 Y2 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin zstop M574 Z1 S2 ; configure Z endstop - high end and uses probe M574 U2 S1 P"ystop" M671 X-260:260:260:-260 Y-227:-227:302:302 S10 ; leadscrews positions - Front left, Front right, Rear ; Z-Probe M950 S0 C"duex.pwm5" ; create servo pin 0 for BLTouch M558 P9 C"^zprobe.in" H5 F600 T9000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y-36 Z2.1 ; set Z probe trigger value, offset and trigger height (larger number = Nozzel closer to the bed) M557 X-220:170 Y-220:170 P8:8 ; define mesh grid ; Thermistors definitions M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp M308 S2 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin e1temp ; Heaters definitions M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 aka S0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 aka S1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2 aka S2 M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H2 S280 ; set temperature limit for heater 2 to 280C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H0 T45:100 ; set fan 1 value. Thermostatic control is turned on M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency M106 P2 S1 H-1 ; set fan 2 value. Thermostatic control is turned off M950 F3 C"duex.fan3" Q500 ; create fan 3 on pin duex.fan3 and set its frequency M106 P3 S0 L0 X255 H-1 ; set fan 3 value. Thermostatic control is turned off M950 F3 C"duex.fan4" Q500 ; create fan 3 on pin duex.fan4 and set its frequency M106 P3 S0 L0 H-1 ; set fan 3 value. Thermostatic control is turned off ; TOOLS ; T0 M563 P0 S"Extruder 1" D0 H1 F3 ; define tool 0 - uses extruder 0, heater 1, and fan 0 for partcooling G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets M305 P0 T100000 B3950 ; Thermistor type G10 P0 R0 S0 ; set initial tool 0, active S and standby R temperatures to 0C ; T1 M563 P1 S"Extruder 2" D1 H2 X3 F4 ; define tool 1 - uses extruder 1, heater 2, motor 3 for X axis and fan 2 for partcooling G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 1, active S and standby R temperatures to 0C ; T2 - duplication tool M563 P2 S"Dublication" D0:1 H1:2 F0:2 ; define duplication tool 2 - uses extruder 0 and 1, heater 1 and 2, and fan 0 and 2 for partcooling G10 P2 X110 Y0 Z0 U-110 ; set duplicaiton tool 2 axis offsets - inverse logic - print 110mm to the left with X and 110mm to the right with U G10 P2 R0 S0 ; set duplication tool initial active-S and standby-R temperatures to 0C M567 P4 E1:1 ; mixing ratios for extruders. i guess it does not even matter or is even needed ; Automatic saving after power loss is enabled M911 S23.00 R23.50 P"M913 X0 Y0 U0 G91 M83 G1 Z2 E-4 F3000" ; Set voltage thresholds and actions to run on power loss ; MISC M501 ; enable config-override. This is so you have your PID tuning there not here. And other stuff like object model -

Here is just one of my Gcodes, one of probably 100 of the same STL

ranging my speed, heat, retraction settings

ranging my speed, heat, retraction settings -

@craigrobbo-0 said in Help with strange under extruding on layer change:

So I decided to turn off retraction and the problem still persists... Pulling my hair out on this!

This just shows how bad they are coming out

-

I cannot edit my original post so i have copied and updated it here:

Hey guys so, I need some help please, so I have built a 3d printer, cartesian using a duet3d on REPRAP firmware version 3.xx

It's all working but for one issue, whenever the extruder retracts or starts a new layer, it doesn't seem to extrude right away leaving missing lines in my print and on the first layers.

I've calibrated e steps several times and also checked retract settings which are fine.

I have no slipping in the gears.I am using a BIQU H2 extruder (I have 2 of them and both do the same)

My slicer is Cura tried 4.7, 4.12 and 4.13

I have tried many of the usual expected slicer settings and some extreme settings

Temps from 190-230c (generally use 210c with PLA+)

speeds from 20mm/s up to 200mm/s (generally use 60mm/s)

Retractions from off upto 3mm and retract speeds of 10mm/m upto 40mm/s (generally use 0.6mm and 30mm/s)

travel speeds I have tried from 60 upto 400mm/s (generally use 120m/s)Where things get a bit stranger is that, my e steps are calibrated perfectly (checked more than 10 times) but it over extruders with 100% flow rate (cura) so have to set flow to 88%...however even at a 100% flow rate the slow extrusion at the start of a layer is still present.

I've tested 2 brand new extruders and both same issue

-

@craigrobbo-0 said in Help with strange under extruding on layer change:

I've tested 2 brand new extruders and both same issue

Is it perhaps an issue with the Biqu extruders themselves?

-

@phaedrux It is a possibility, I have stripped them down to as many pieces as i could and rebuilt them and they seem okay?