1HCL Closed Loop - layer shifts - Timing?

-

@gruna-studio there are no significant differences for the EXP1HCL between 3.4.0rc1 and rc2, apart from the bug fixes related to homing moves. The PD algorithm hasn't changed between RC1 and RC2.

Can you quantify the size of the layer shift? In particular, is it always 4 full steps, or a multiple of 4 full steps? Does anything in particular provoke it?

-

@gruna-studio it would be a good idea to baseline the printer in open loop mode first. then switch to closed loop mode and we can look at the PID tuning.

-

the shifts are different. At the beginning they have been small and often, now after tuning and change timing, the shifts are bigger but less often.

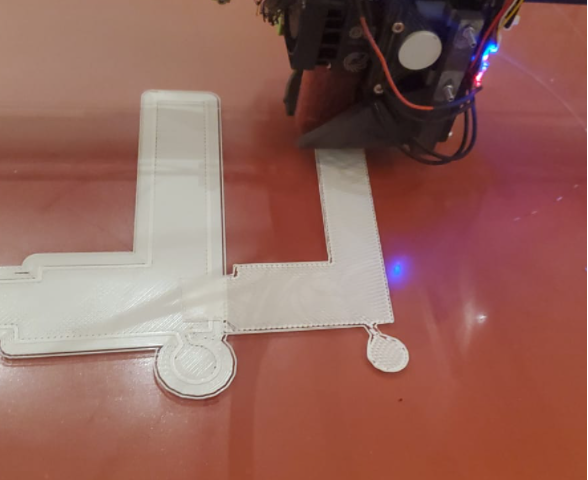

PIC 1

less shifts in not-round models...

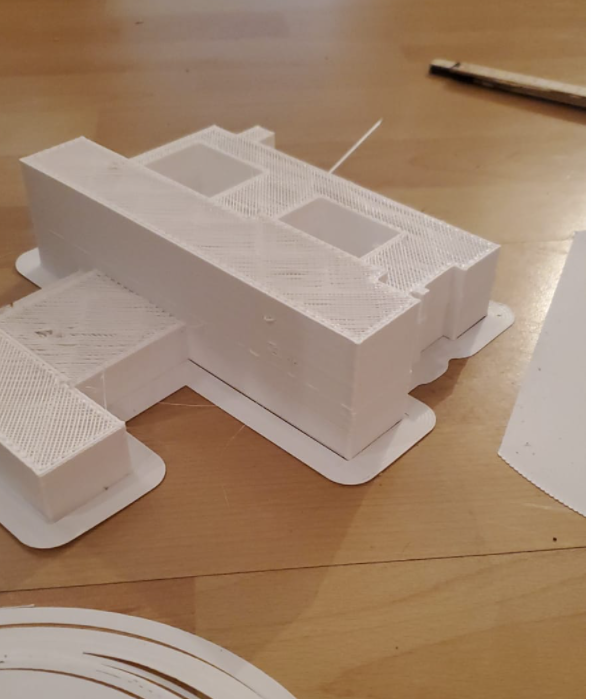

PIC 2: ---Actual settings!

print and shifting for the settings at the moment... I homed x after shift in layer 2 again. ( X shift at layer 2, second shift in Y axis in layer 10)

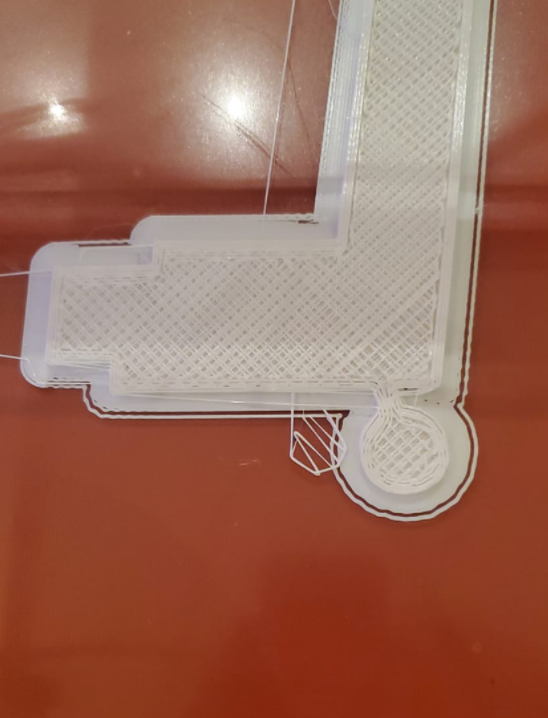

Pic 3:

Older test with shifts which I can saw every round on the position where X has to turn or come to Zero and Accelarate again.

On the left site you can see shaking which was sometimes ended up in shifts. This shaking was in the Y axis motors (both) and sometimes let it stopp X for a small while. Timing was helpful, but there still shifts like you see.

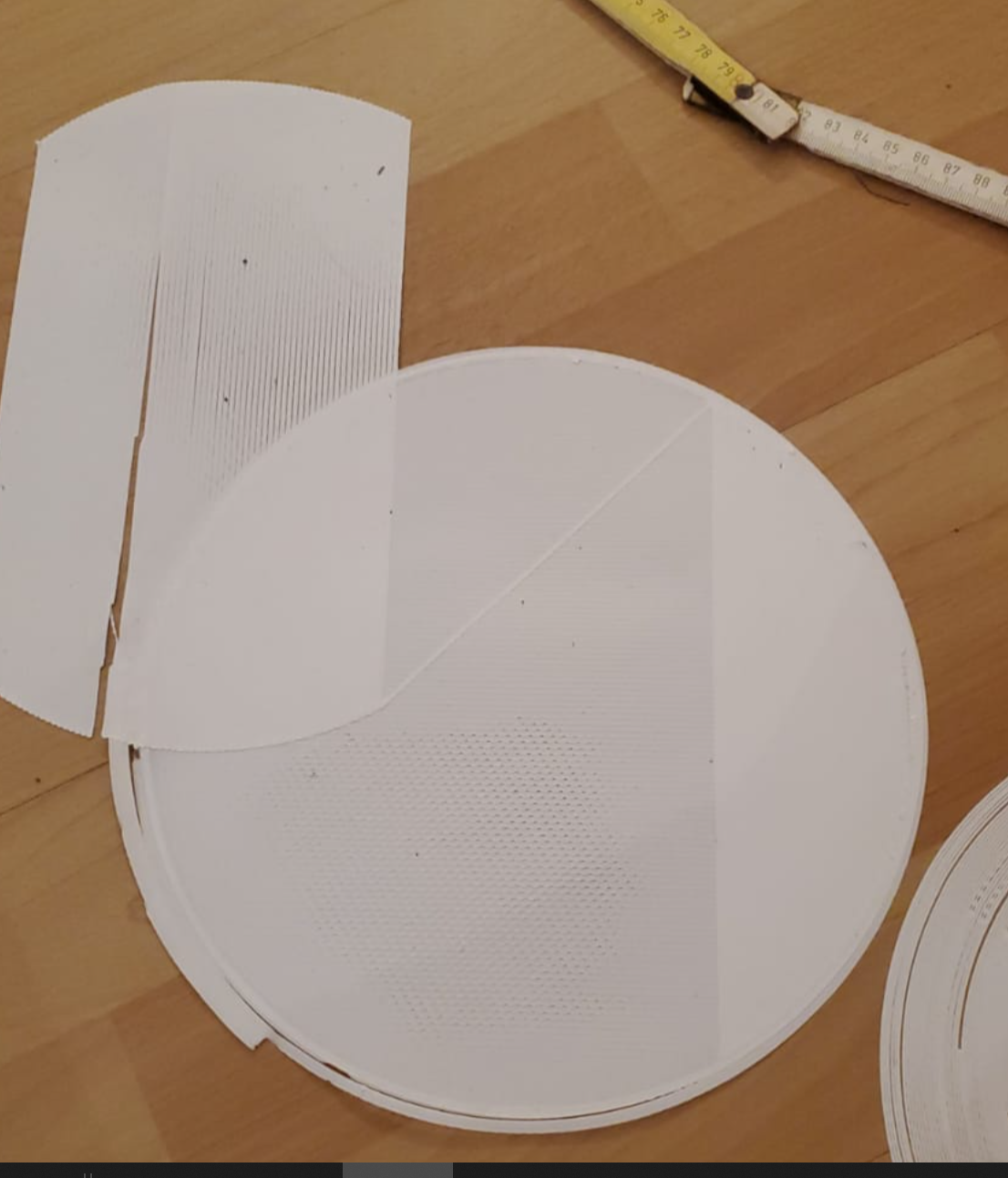

PIC 4

Then I was changing the Timing and that heppened...

The Can connecting till the last board is 11 Meter long, is this a problem?

I changed timing to T10:10:15:15 --> same shifts like before with higher numbers.

@T3P3Tony Do I have really to print in open loop, first?

I was printing with this printer almost 1 Year without bigger problems, no I installed just the 1HCL´s and new motors.Thanks a lot for your replys.

Richard

-

@gruna-studio Changing the settings while the print is progressing may well cause shifts. I have not tested that.

I think it would be good to test in open loop mode. This just requires changing the D parameter of the M569 command. not hardware changes needed.

-

I haven´t changed settings while printing.

just between the prints...So next step print in open loop?

I´´ll write when Test is done...

thanks a lot

-

This post is deleted! -

-

-

@gruna-studio said in 1HCL Closed Loop - layer shifts - Timing?:

Problem solved

What was the problem? Loose pulley, perhaps?

-

NO MECHANICAL issue --- of course --- since two weeks I try to solve this problem and it would be very stupid of mine when it would be a pulley. Also I described that different axis are shifting and that the motor is shaking and also just stopping sometims.

I´m sorrybroken expansion board

-

@gruna-studio which, the 1HCL expansion board? How was it broken? We will probably want that back for investigation.

-

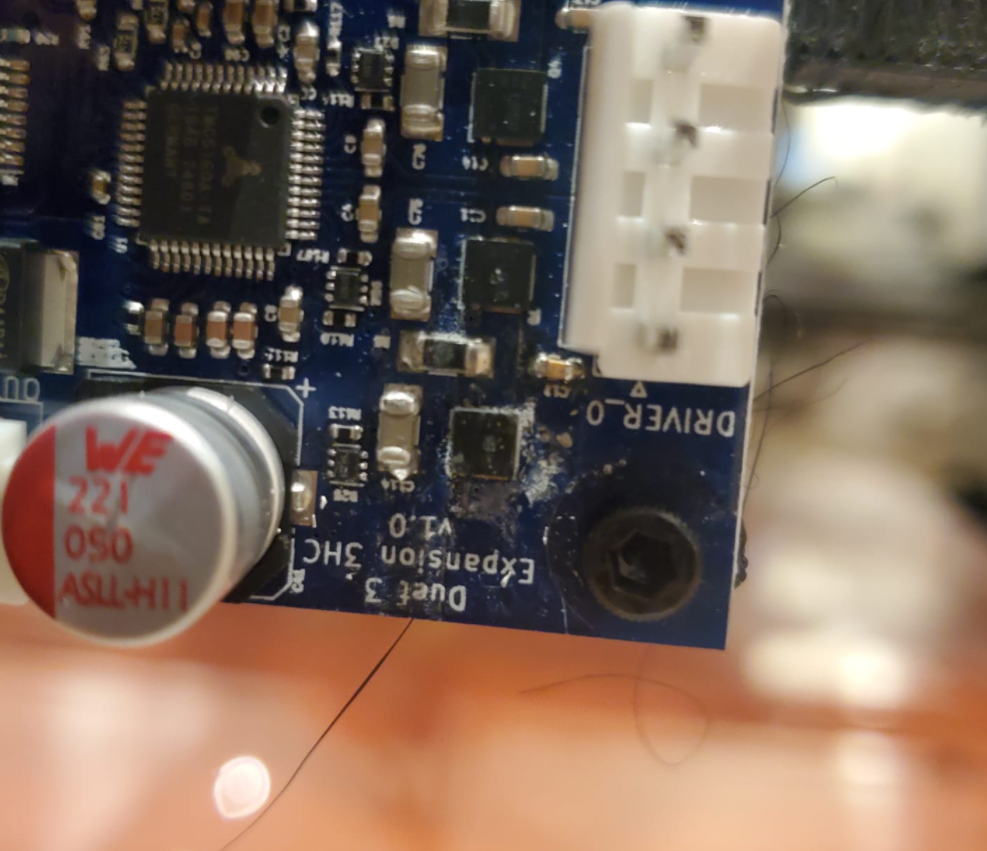

Duet3 3HC expansion board has a small burninig on it. I will send a picture. I haven´t used it before.

But crazy issue for a burned board.Just a last quick question.

How to calculate the steps per mm in closed loop? same way like open loop but no microsteps?

I have a gt2 with 20 teeth = 40 mm

200 steps per revolution / 40 = 5 ----I have 100steps/ mm (which is crazy high) but the models are printed only 20 per cent to big. How can that be?

thanks

Richard -

@gruna-studio

-

@gruna-studio thanks for confirming that - can you email warranty@duet3d.com to arrange a replacement referencing this thread.

I think the issue with microsteps on your setup is because the scaling provided by M350 is still having an impact. 100 steps/mm does not sound right. I expect you have M350 set to 16 (which is the default where microstepping applies) which would be a steps/mm setting of 80 in your setup. (16*5 = 80). If you would prefer to work in full steps then set M350 to 1 and M92 to 5.

edited to add an update:

The microstep setting should be high enough to use the full encoder CPR. e.g. if the encoder is 1000 PPR (so 4000 CPR) and the full steps/rev is 200, then the microstepping needs to be at least 4000/200 = 20 to make use of the full resolution of the encoder.

So in that case I would use M350 X32, and M92 X160 (adjust for the other axis you have with 1HCL.).

-

@gruna-studio I have also updated the documentation page to make this clear:

https://docs.duet3d.com/en/Duet3D_hardware/Duet_3_family/Duet_3_Expansion_1HCL#microstepping -

@t3p3tony

ok great information!!

It´s working great, now. It´s kind of crazy this closed loop system.

thanks for updating the documentation.cheers

richard -

@t3p3tony said in 1HCL Closed Loop - layer shifts - Timing?:

@gruna-studio thanks for confirming that - can you email warranty@duet3d.com to arrange a replacement referencing this thread.

did you see this regarding the damaged expansion board?

-

@t3p3tony

Yes. Sry

I'll do it

Cheers -

Are there some new information about tuning 2 motors an the same axis?

Would be very nice

Cheers

Richard -

@gruna-studio not yet. Do you mean the basic closed loop tuning that you need to do on every power up, or PID tuning?