Help with v-core 3 500mm

-

Hi

Newbie with a V-core 3 500mm standalone duet 3 wifi

I'm using:

Mosquito magnum

slice engineering nozzle heater

PT1000 thermistor

orbiter 1.5

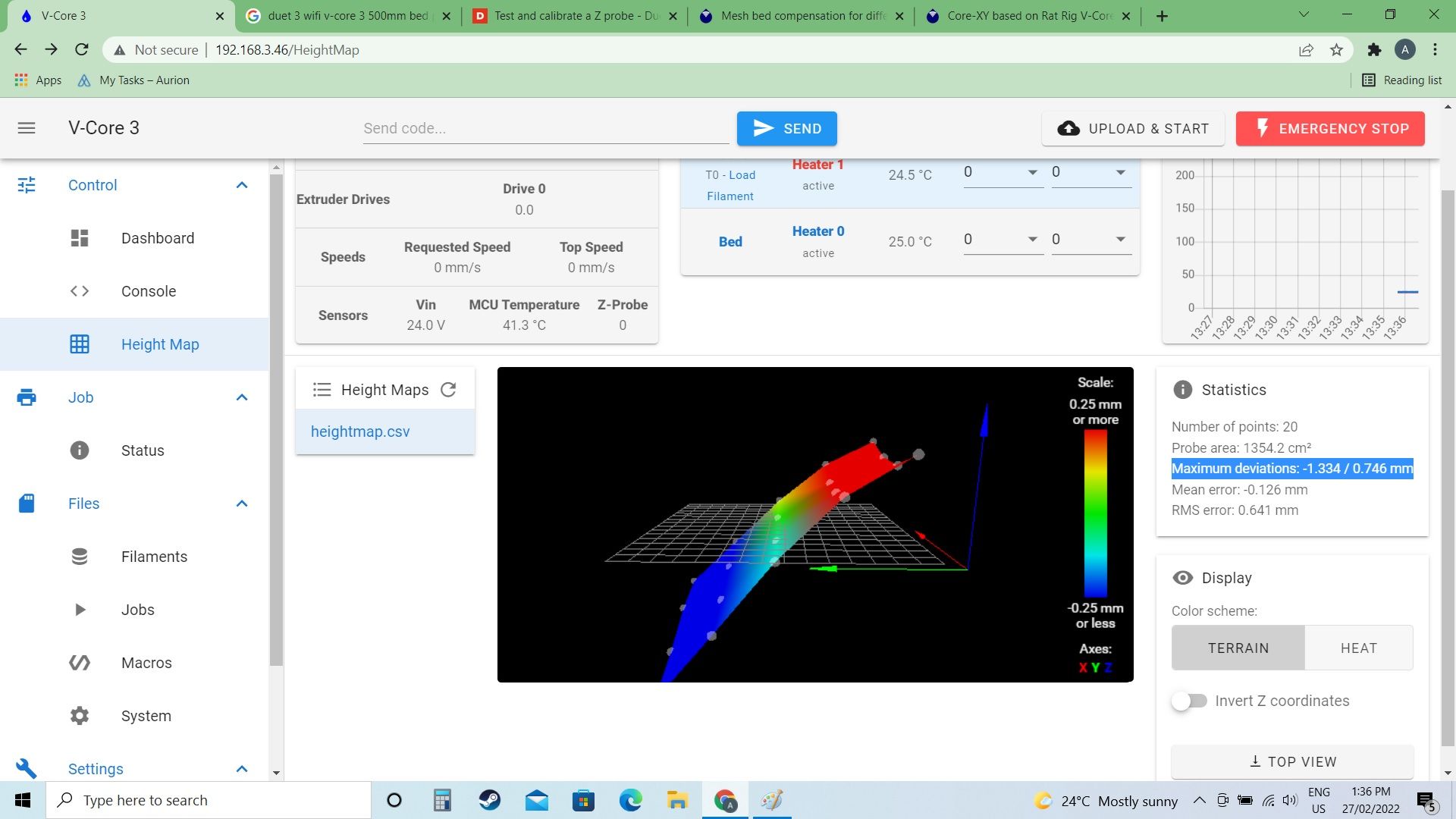

antclabs bl touchI cant seem to get the bed leveled ( attached pic) and i'm pretty sure i haven't configured the heaters right either. Only the heater fan works for some reason. I have attached the relevant files. What am i doing wrong? Any help with leveling and heaters would be much appreciated.

homez.g homey.g homex.g homeall.g config.g bed.g

-

-

-

Looks like you have three Z steppers - is that correct?

If so please copy-and-paste the following configuration files using the </> tag, one tag per file.

- config.g

- homeall.g

- homex.g

- homey.g

- homez.g

- bed.g

- mesh.g

Thanks.

Frederick

-

Yes three Z motors. I dont have a Mesh file.

Config.g; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"V-Core 3" ; set printer name M669 K1 ; CoreXY G29 S1 ; Set Units to Millimeters ; Network M552 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S1 D3 ; physical drive 0.0 goes forwards ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"V-Core 3" ; set printer name M669 K1 ; CoreXY G29 S1 ; Set Units to Millimeters ; Network M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S0 D3 ; physical drive 0.0 goes forwards M569 P0.1 S0 D3 ; physical drive 0.1 goes forwards M569 P0.2 S0 D3 ; physical drive 0.2 goes forwards M569 P0.3 S1 D3 ; physical drive 0.3 goes forwards M569 P0.4 S1 D3 ; physical drive 0.4 goes forwards M569 P0.5 S1 D3 ; physical drive 0.5 goes forwards M584 X0.4 Y0.3 Z0.0:0.1:0.2 E0.5 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z800.00 ; set steps per mm M906 X1000 Y1000 Z800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout M566 X400.00 Y400.00 Z6.00 E120.00 P1 ; set maximum instantaneous speed changes (mm/min) M203 X10800.00 Y10800.00 Z1000.00 E3600.00 ; set maximum speeds (mm/min) M201 X3000.00 Y3000.00 Z100.00 E3600.00 ; set accelerations (mm/s^2) ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X500 Y500 Z500 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io0.in" ; configure active high endstops M574 Y2 S1 P"io1.in" ; configure active high endstops M671 X60:270:500 Y50:490:50 S5 ; define positions of Z leadscrews or bed levelling screws M557 X60:480 Y50:480 P5 ; define 5x5 mesh grid ; Heaters M308 S0 P"temp1" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp1 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M307 H0 R1.099 C297.8 D4.67 S0.50 B0 ; PID Tuning for Heater0, Heated Bed (85C) ;M307 H0 R0.860 C439.9 D11.80 S1.00 B0 ; PID Tuning for Heater0, Heated Bed (45C) M143 H0 S120 ; Set temperature limit for Heater0 to 120C M308 S1 P"temp2" Y"pt1000" ; configure sensor 1 as PT1000 on pin temp2 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 ;M307 H1 R2.517 C121.8:105.0 D3.66 S1.00 V24.1 ; PID Tuning for Heater1, Extruder0 (230C) M307 H1 R2.794 C119.4:105.8 D3.09 S1.00 V24.1 B0 ; PID Tuning for Heater1, Extruder0 (200C) M143 H1 S285 ; Set temperature limit for heater 1 to 285C ;M308 S2 P"temp2" Y"thermistor" A"Chamber" T100000 B4725 C7.060000e-8; Define Sensor2 as Chamber temperature (Semitec 104GT2) M308 S3 Y"mcu-temp" A"MCU" ; Define Sensor3 as the integrated MCU temperature sensor M308 S4 Y"drivers" A"TMC Drivers" ; Define Sensor4 as the TMC overheat sensor ; Fans M950 F0 C"out3" Q500 ; create fan 0 on pin out3 and set its frequency M106 P0 C"Hotend Fan" S0 H1 T45 L255 ; set fan 0 name and value. Thermostatic control turned on for Hotend M950 F1 C"out4" Q500 ; create fan 1 on pin out4 and set its frequency M106 P1 C"Layer Fan" S0 H-1 L255 ; set fan 1 name and value. Thermostatic control is turned off ; Tools M563 P0 D0 H1 F1 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M950 H1 C"out1" T1 ; create nozzle heater output on out2 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S250 ; set the maximum temperature in C for heater ; EVA 2 / BMG / E3D V6 M92 E830 ; set extruder steps per mm, 0.9 angle/step (LDO Pancake) M906 E800 ; set extruder motor current (mA) and idle factor in per cent ; Z-Probe ;; Inductive Probe ; M558 P5 C"!io3.in" H5 F400 T5000 ; set Z probe type to unmodulated and the dive height + speeds ; G31 P500 X-30 Y-15 Z0.20 ; set Z probe trigger value, offset and trigger height, more Z means closer to the bed BLTouch M950 S0 C"io2.out" ; Create a servo pin on io2 M558 P9 C"io2.in" H5 F240 T10800 A5 ; set Z probe type to unmodulated and the dive height + speeds G31 P25 X-28.00 Y-13.00 Z0.90 ; set Z probe trigger value, offset and trigger height, more Z means closer to the bed ; Pressure Advance ; M572 D0 S0.10Bed.g

; this script compensates for what the Z offset is ; so if G31 P500 X-30 Y-15 Z1.7 then first probe will be at ; X30 Y20 (when G30 P0 X0 Y5) M561 ; clear any bed transform G29 ; probe the bed and enable compensationhomeall.g

M201 X500.00 Y500.00 ; Reduce acceleration for homing moves ; BLTouch ;M280 P0 S160 ; Precautionary alarm release ;M280 P0 S90 ; Ensure the pin is raised G91 ; Relative positioning G1 H2 Z5 F6000 ; Lift Z relative to current position G1 H1 X-625 Y605 F3600 ; Move quickly to X and Y axis endstops and stop there (first pass) G1 H1 X-625 F1800 ; Move quickly to X and Y axis endstops and stop there (first pass) G1 H1 Y605 F1800 ; Move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X1 Y-1 F600 ; Go back a few mm G1 H1 X-625 Y605 F360 ; Move slowly to X and Y axis endstops once more (second pass) G1 H1 X-625 F360 ; Move slowly to X and Y axis endstops once more (second pass) G1 H1 Y605 F360 ; Move slowly to X and Y axis endstops once more (second pass) M201 X3000 Y3000 ; Return to full acceleration G90 ; Absolute positioning ;G1 X150 Y150 F10000 ; Go to the center of the bed (300x300) ;G1 X200 Y200 F10000 ; Go to the center of the bed (400x400) G1 X250 Y250 F10000 ; Go to the center of the bed (500x500) G30 ; Home Z by probing the bed G91 ; Relative positioning G1 Z5 F100 ; Lift Z relative to current position G90 ; Absolute positioningHomex.g

M201 X500.00 Y500.00 ; Reduce acceleration for homing moves G91 ; Relative positioning G1 H2 Z5 F6000 ; Lift Z relative to current position G1 H1 X-625 F3600 ; Move quickly to X endstop and stop there (first pass) G1 H2 X1 F600 ; Go back a few mm G1 H1 X-625 F360 ; Move slowly to X endstop once more (second pass) M201 X3000 Y3000 ; Return to full acceleration G1 H2 Z-5 F6000 ; Lower Z relative to current position G90 ; Absolute positioninghomey.g

M201 X500.00 Y500.00 ; Reduce acceleration for homing moves G91 ; Relative positioning G1 H2 Z5 F6000 ; Lift Z relative to current position G1 H1 Y605 F3600 ; Move quickly to Y endstop and stop there (first pass) G1 H2 Y-1 F600 ; Go back a few mm G1 H1 Y605 F360 ; Move slowly to Y endstop once more (second pass) M201 X3000 Y3000 ; Return to full acceleration G1 H2 Z-5 F6000 ; Lower Z relative to current position G90 ; Absolute positioninghomez.g

; BLTouch ;M280 P0 S160 ; Precautionary alarm release ;M280 P0 S90 ; Ensure the pin is raised G91 ; Relative positioning G1 H2 Z5 F6000 ; Lift Z relative to current position G90 ; Absolute positioning ;G1 X150 Y150 F10000 ; Go to the center of the bed (300x300) ;G1 X200 Y200 F10000 ; Go to the center of the bed (400x400) G1 X250 Y250 F10000 ; Go to the center of the bed (500x500) G30 ; Home Z by probing the bed ; Uncomment the following lines to lift Z after probing G91 ; Relative positioning G1 Z5 F100 ; Lift Z relative to current position G90 ; Absolute positioning -

This is a little out of date but it covers Auto Bed Leveling using G32:

Note this part:

G32 probing uses a bed.g file to define the probe points individually, including an optional Z probe trigger height adjustment for each point. On a Delta printer it is used for auto calibration. On a Cartesian or CoreXY printer it is used for leadscrew adjustment if you have multiple independently-driven Z leadscrews.

Also note that Mesh Bed Compensation using G29 is a different feature though sometimes you will see it mentioned with leveling.

The current firmware expects heightmap creation needed for Mesh Bed Compensation to be done in a file called mesh.g. This leaves bed.g for just doing bed leveling.

The DWC expects G29 to invoke mesh.g and create the height map.

The DWC expects G32 to invoke bed.g and level the bed (either manual or automatic).

Frederick

-

@fcwilt Thank you

-

@duetnewbie said in Help with v-core 3 500mm:

G29 S1 ; Set Units to Millimeters

Note that this, the 6th line of your config.g, loads the default bed map. G29 S1 loads the bed mesh; G21 sets units to millimeters. It's an error on this page: https://v-core.ratrig.com/firmware/

Ian

-

Not that it's perfect and will require some changes from your config. But : https://github.com/Nurgelrot/RatRig-VCore-3-Configs/

I suggest you joining the RatRig Discord server. the Duet channel there has a few people to help with that specific printer.