Looking some input shaping advise on this graphs

-

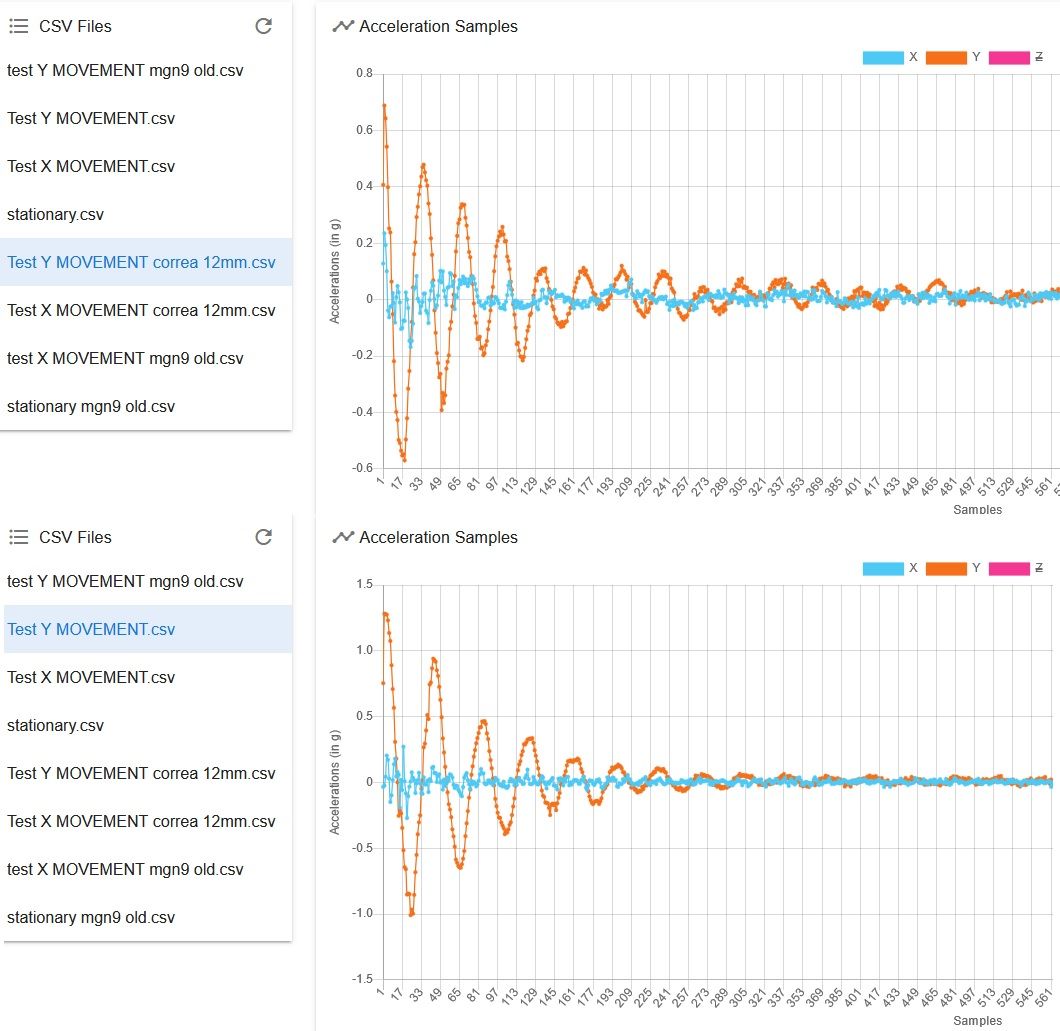

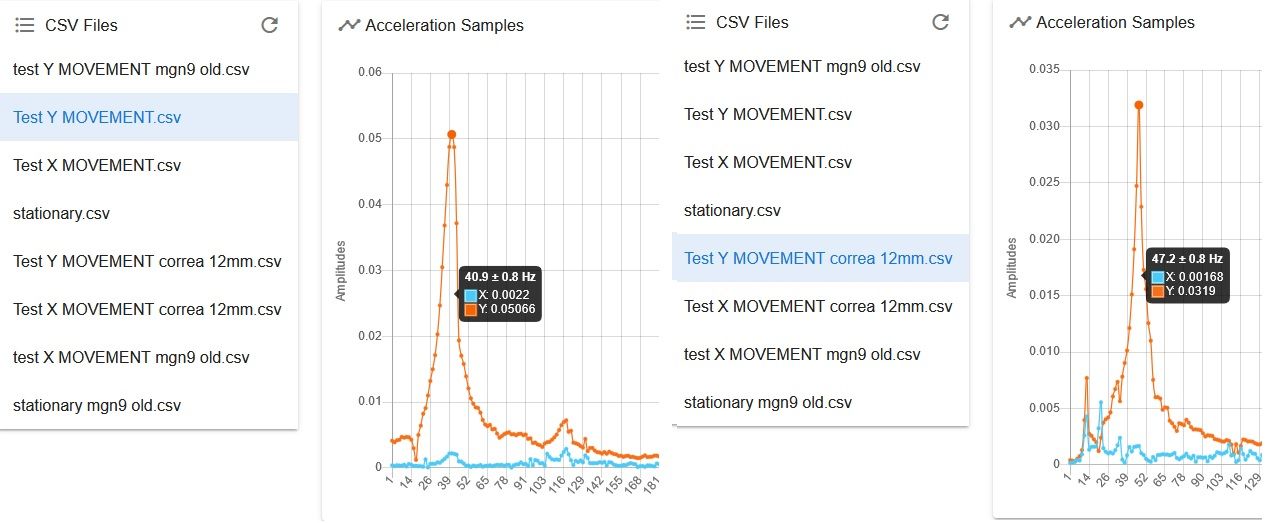

Hi there, I recently installed an accelerometer and did some readings. I am comparing the same system, first time with 12mm gt2 belts and after 6mm ones. All the rest is the same. The test was 200mm , at 10.000 acceleration and 1000mmxs.

As far as I can understand the 12mm is better because they have less amplitude and less wide peak. What do you guys think about it or can you point me something I can do better?

-

@zabana as you say the ringing with the 12mm belt has less amplitude, also it has a higher frequency, 47.2Hx instead of 40.9Hz. However, the damping factor looks a little higher with the 6mm belt.

ZVD or ZVDD or perhaps MZV input shaping should be able to handle either. The higher frequency when using 12mm belts would make allow a slightly higher print speed.

-

@dc42 said in Looking some input shaping advise on this graphs:

@zabana as you say the ringing with the 12mm belt has less amplitude, also it has a higher frequency, 47.2Hx instead of 40.9Hz. However, the damping factor looks a little higher with the 6mm belt.

ZVD or ZVDD or perhaps MZV input shaping should be able to handle either. The higher frequency when using 12mm belts would make allow a slightly higher print speed.

How do you read damping factor from the graph? Less "swinging" in the graph timeline = higher damping? How would one translate that to IS damping factor?

-

@dc42 thanks a lot for the response! I not really understand yet the damping factor and another things related to the use of the input shaping and how to read it from the graph.

I think I will go for the 12mm belts (6mm ones was just a test to confirm with the module what I suspect by eye sight) but you did not mention EI2 or EI3, are them not a good choice for this frequency?

I tried to use the new plugin but can´t undertand how it works, is there any guide or reference page to check how it works?

Thanks again!!!

-

@zabana said in Looking some input shaping advise on this graphs:

@dc42 thanks a lot for the response! I not really understand yet the damping factor and another things related to the use of the input shaping and how to read it from the graph.

I think I will go for the 12mm belts (6mm ones was just a test to confirm with the module what I suspect by eye sight) but you did not mention EI2 or EI3, are them not a good choice for this frequency?

I tried to use the new plugin but can´t undertand how it works, is there any guide or reference page to check how it works?

Thanks again!!!

ei2 and ei3 take significantly longer to execute and limit your speed and acceleration.

With such a narrow frequency band it's usually enough to attack them with a lower order shaper like ZVD or MZV as they run significantly shorter (but also only attack a more narrow range).

If I'm not mistaken MZV runs for 0.75/freq, ZVD for 1/freq and ei2 and ei3 somewhere in the range of 1.5/freq to 2/freq.

In Klipper you get "smoothing" (round corners, wider holes) if the shaper runs longer than what can be squeezed into the acceleration timeframe and Duet just ignores the shaper and doesn't apply it at all in that case (I think at least that's what @dc42 stated a while ago).

Therefore with higher order shapers you need to run a lower acceleration for them to be effective/not have a negative impact) while with lower order shapers you can go quicker.

-

@bberger thanks for the explanation! I will try it so I can see what gives better prints