I got fed up of constantly tweaking the K-Factor calibration for Marlin that you can download, so I wrote a little Macro that can be run from the Duet.

This is also by far the most reliable method for me for determining pressure advance.

https://gist.github.com/bernhardberger/555c4913d492a5213b49b2efa4f0b24e

This should work for Delta printers with the origin (0,0) at center and also cartesian printes with origin at the edge of the bed.

There are no sanity checks (yet), so be careful.

Any suggestions welcome.

Please use the code from the Gist, somehow the forum feature breaks the pasted code (adds {1} instead of newlines..?)

; adjust values to your needs

var temp_nozzle = 195

var temp_bed = 55

var nozzle_diameter = 0.6

var layer_height = 0.1618

var line_width = 0.6

var pa_start = 0

var pa_end = 0.05

var pa_step_size = 0.002

var print_speed_slow_mms = 30

var print_speed_fast_mms = 200

var travel_speed_mms = 300

var travel_speed_z_mms = 300

var line_spacing = 5

var origin_x = 0

var origin_y = 0

var bed_center = true

var line_length_slow = 40

var line_length_fast = 100

var fan_speed = 0.0 ; range 0.0...1.0

var dwell_time_milliseconds = 2000

var prime_nozzle = false

var prime_nozzle_macro = "0:/macros/_Printing/prime_nozzle.g" ;set to "" (empty string) if you don't want to prime the nozzle, otherwise enter the macro location

M291 R"Pressure Advance Calibration" P{"Start Factor: " ^ {var.pa_start} ^ ", End Factor: " ^ {var.pa_end} ^ ", Steps: " ^ {var.pa_step_size}}

; [!!!!!] DO NOT CHANGE VALUES AFTER THIS LINE [!!!!!!]

;------------------------------------------------------

; calculated values start

var print_speed_slow = {var.print_speed_slow_mms * 60}

var print_speed_fast = {var.print_speed_fast_mms * 60}

var travel_speed = {var.travel_speed_mms * 60}

var travel_speed_z = {var.travel_speed_z_mms * 60}

; extrusion calculation taken from slic3r docs (https://manual.slic3r.org/advanced/flow-math)

; A = rectangle + circle = (line_width - layer_height)*layer_height + pi(layer_height/2) * pi(layer_height/2)

var e_per_mm = {(var.line_width - var.layer_height) * var.layer_height + (pi * ((var.layer_height/2) * (var.layer_height/2)))}

; calculated values end

G21 ; Millimeter units

G90 ; Absolute XYZ

M83 ; Relative E

T0 ; Switch to tool 0

M104 S{var.temp_nozzle}

M190 S{var.temp_bed}

G1 Z5 F{var.travel_speed_z} ; move nozzle down

M109 S{var.temp_nozzle} ; Wait for nozzle temp

;M204 S5000 P5000; Acceleration

G92 E0 ; Reset extruder distance

M106 S{var.fan_speed} ;turn off fan

G1 X0 Y0 F{var.travel_speed} ; move nozzle to center

G1 Z{var.layer_height} F{var.travel_speed_z} ; Move to layer height

M572 D0 S0 ;reset pressure advance

; ==== PRIME NOZZLE START ====

if var.prime_nozzle == true

if var.prime_nozzle_macro != ""

M98 P{var.prime_nozzle_macro}

; ==== PRIME NOZZLE END ====

var line_length_total = {2 * var.line_length_slow + var.line_length_fast}

var pos_x_start = 0

var pos_y_start = 0

if var.bed_center == true

set var.pos_x_start = {-1 * (var.line_length_total / 2)}

set var.pos_y_start = {-1 * var.line_spacing * ((var.pa_end - var.pa_start) / var.pa_step_size) / 2}

var pos_x_end = {var.pos_x_start + var.line_length_total}

var pos_y_end = {var.pos_y_start + var.line_spacing * ((var.pa_end - var.pa_start) / var.pa_step_size)}

var anchor_y_start = {var.pos_y_start - var.line_spacing}

var anchor_y_end = {var.pos_y_end + var.line_spacing}

var anchor_y_length = {sqrt(0 + (var.anchor_y_end - var.anchor_y_start) * (var.anchor_y_end - var.anchor_y_start))} ; we only move in the y plance

; ==== ANCHOR FRAME START ====

G1 X{var.pos_x_start} Y{var.anchor_y_start} F{var.travel_speed} ; move to start

G11 ; un-retract

G1 X{var.pos_x_start} Y{var.anchor_y_end} E{var.e_per_mm * var.anchor_y_length} F{var.print_speed_slow} ; print line

G1 X{var.pos_x_start + var.line_width} Y{var.anchor_y_end} F{var.travel_speed} ; move to start

G1 X{var.pos_x_start + var.line_width} Y{var.anchor_y_start} E{var.e_per_mm * var.anchor_y_length} F{var.print_speed_slow} ; print line

G10 ; retract

G1 X{var.pos_x_end} Y{var.anchor_y_start} F{var.travel_speed} ; move to start

G11 ; un-retract

G1 X{var.pos_x_end} Y{var.anchor_y_end} E{var.e_per_mm * var.anchor_y_length} F{var.print_speed_slow} ; print line

G1 X{var.pos_x_end - var.line_width} Y{var.anchor_y_end} F{var.travel_speed} ; move to start

G1 X{var.pos_x_end - var.line_width} Y{var.anchor_y_start} E{var.e_per_mm * var.anchor_y_length} F{var.print_speed_slow} ; print line

G10 ; retract

; ==== ANCHOR FRAME END ====

G4 P{var.dwell_time_milliseconds} ; Pause (dwell) for specified milliseconds

; ==== TEST PATTERN START (loop) ====

var pa_current = {var.pa_start}

var pos_y_current = {var.pos_y_start}

while {var.pa_current <= var.pa_end}

G1 X{var.pos_x_start} Y{var.pos_y_current} F{var.travel_speed} ; move to start

M118 S"M572 D0 S " ^ {var.pa_current} L1

M572 D0 S{var.pa_current} ; set PA factor

G11 ; un-retract

G1 X{var.pos_x_start + var.line_length_slow} Y{var.pos_y_current} E{var.e_per_mm * var.line_length_slow} F{var.print_speed_slow} ; print slow line

G1 X{var.pos_x_start + var.line_length_slow + var.line_length_fast} Y{var.pos_y_current} E{var.e_per_mm * var.line_length_fast} F{var.print_speed_fast} ; print fast line

G1 X{var.pos_x_end} Y{var.pos_y_current} E{var.e_per_mm * var.line_length_slow} F{var.print_speed_slow} ; print slow line

G10 ; retract

set var.pa_current = {var.pa_current + var.pa_step_size}

set var.pos_y_current = {var.pos_y_current + var.line_spacing}

; ==== TEST PATTERN END ====

M0 ;finish

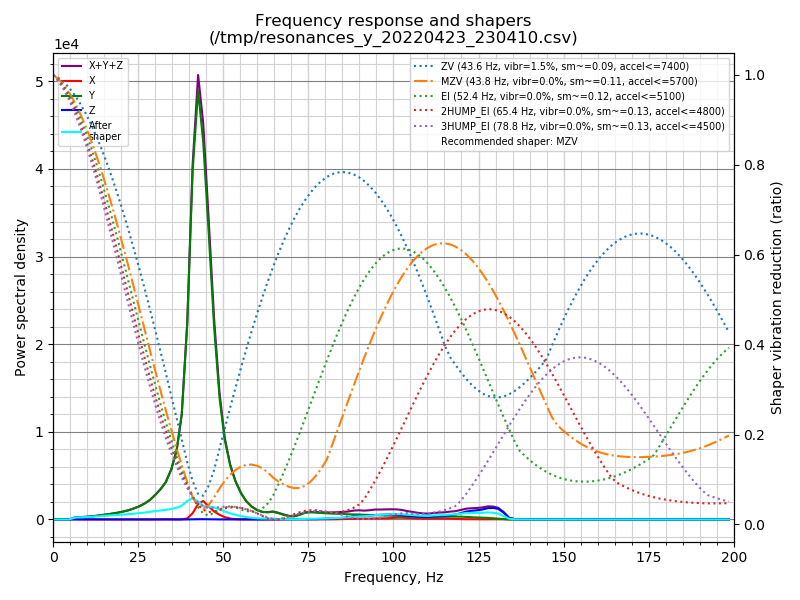

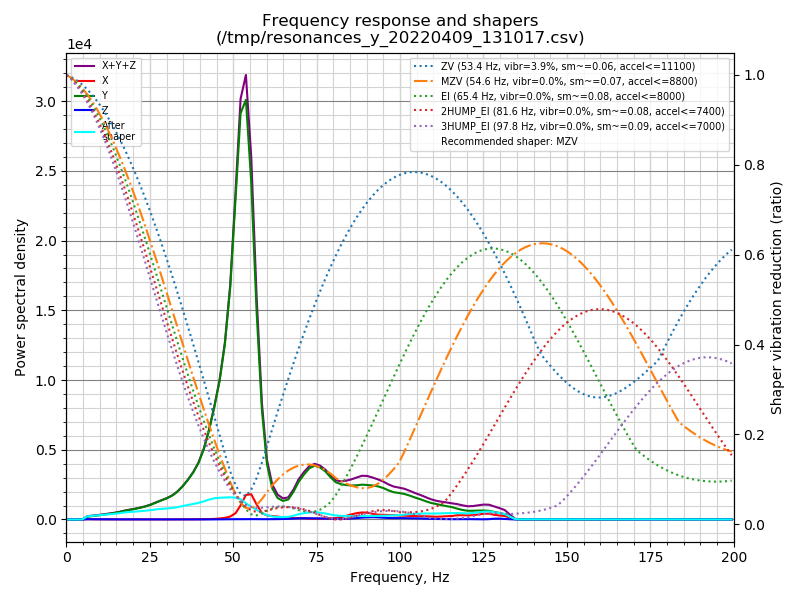

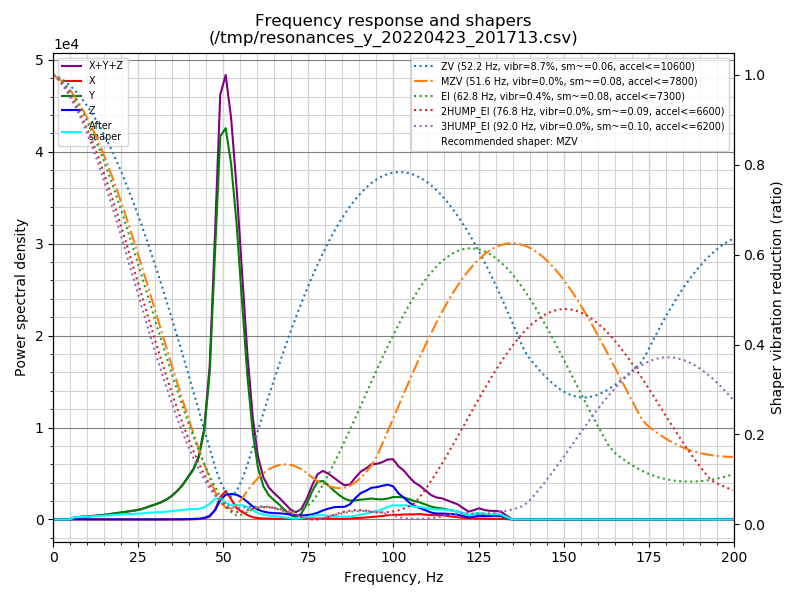

Been a happy 3.4 early adopter for quite some time now and Input Shaping brings so much to the table. Exciting times! Hopefully the IS Plugin gets to the point of comfort and ease-of-use as in Klipper!

Been a happy 3.4 early adopter for quite some time now and Input Shaping brings so much to the table. Exciting times! Hopefully the IS Plugin gets to the point of comfort and ease-of-use as in Klipper!