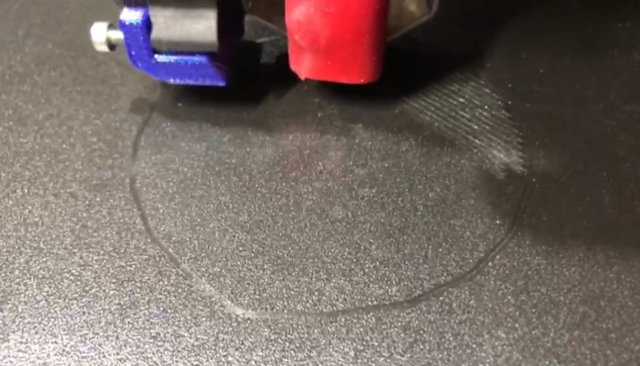

Printing problem duet fw config bad or Siemens drivers bad

-

@createc3d post your config

-

@createc3d it may be that the drivers need slower timings than the default ones provided by the 1XD boards. Please post a link to the datasheet for those drivers, along with your config.g file.

-

@dc42 the drivers are this:

https://support.industry.siemens.com/cs/dl-media/109793552/142040542347_en-US/start.htm?lc=enand the config file is:

; Configuration file for Duet 3 (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.10 on Thu Feb 24 2022 09:21:45 GMT+0100 (hora estándar de Europa central) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Atarfil" ; set printer name M575 P1 S1 B57600 ; Wait a moment for the CAN expansion boards to start G4 S2 ; Network M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P40 S0 R0 T2.7 ; physical drive 121.0 goes forwards M569 P41.0 S1 R0 T2.7 ; physical drive 122.0 goes forwards M569 P42.0 S1 R0 T2.7 ; physical drive 123.0 goes forwards M569 P43.0 S1 R0 T2.7 ; physical drive 124.0 goes forwards M569 P0 S0 R0 ; R0 MODIFICACION M584 X40.0 M584 Y41.0 M584 Z42.0 M584 Z43.0 M584 E0 ; set drive mapping M350 X11.11 Y6.25 Z10 E16 I1 ; configure microstepping with interpolation M92 X11.11 Y6.15 Z200 E600 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z100.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z10.00 E250.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E1680 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X2200 Y200 Z70 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin 121.io0.in M574 Y1 S1 P"io2.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin 122.io0.in M574 Z1 S1 P"io3.in+io4.in" ; configure switch-type (e.g. microswitch) endstop for low end on Z via pin 123.io0.in ; configure switch-type (e.g. microswitch) endstop for low end on Z via pin 123.io0.in ; Z-Probe M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed M557 X15:215 Y15:195 S20 ; define mesh grid ; Heaters M308 S0 P"temp3" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"out0" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 A340 C2745.9 D25 S1.00 B0 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"out1" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 R1.278 C282.5 D6.68 S1.00 V23.1 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; Fans M950 F0 C"out5" Q500 ; create fan 0 on pin out4 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"out4" Q500 ; create fan 1 on pin out5 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools ;M563 P0 S”v4” D0 H1 ; Define tool 0 M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

@createc3d I was unable to find the parameters required in the document you linked to. The parameters needed are:

Minimum step pulse width

Minimum step pulse interval

Required setup time from change in direction signal to leading edge of step pulse

Required hold time from trailing edge of step pulse to change in direction signalCurrently you have set all of these to 2.7 microseconds. I suspect that at least one of them needs to be increased.

Please upgrade to firmware 3.4.0 if you are not already using it.

-

@dc42 I asked Siemens about the data needed and the only thing they can say is this:

They use RS 485 to receive pulses at a máximum frecuency of 1MHz...

They don't tell us anything about "ms" or anything else.

We may increase randomly to see if it works fine?

-

@createc3d in your M569 commands I suggest you try this T parameter:

T2.5:2.5:5:5

If that works, try reducing the last value to zero. It's usually the third value that needs to be increased when there are issues with direction changes.

-

@dc42 Ok, we'll try next week and let you know, because the machine is in other company and can't go to check today.

Thank you.

-

@dc42 hello, we've been testing and it's a bit better but still it's not good.

We tried with T2.5:2.5:5:5 but it was not better.

Then with T2.5:2.5:5:0 was a little improvement.

Then we tried increasing the third value to 10, 20... up to 100 but no change, same results.

We also tried without the T parameter and values and the results was the same that T2.5:2.5:5:0.

Can we try anything else?

-

@createc3d try T5:5:10:10

-

@jay_s_uk Hello, still is not doing it right

-

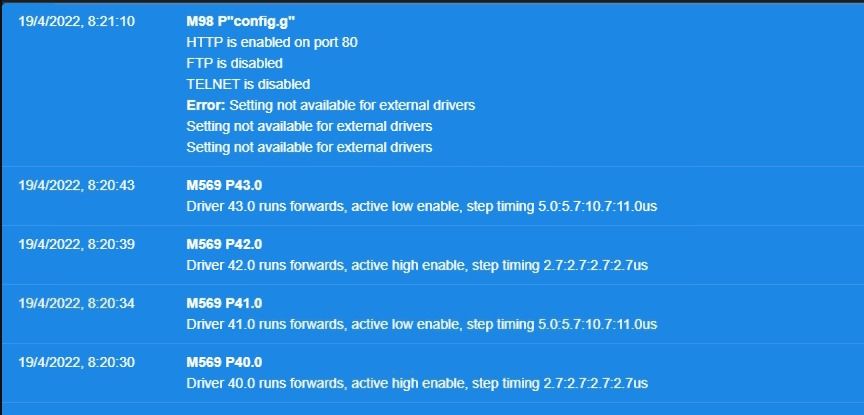

@createc3d if you send M569 P41.0 and similarly for the CAN addresses of the other 1XD boards, does it report the correct T values that you used? Some of them will be rounded up to the next multiple of 1.33us.

If you send M98 P"config.g" are there any error messages?

-

PS have you checked for loose pulleys etc.? That pattern of a straight line segment appearing in what should be a circle is characteristic of a large amount of backlash.

-

@dc42 Hello, sorry for delay, here with easter week we didn't have the possibility to go to the place where the machine is installed until today.

This is the result of M98 P"config.g"

P40 and P41 are X and Y axis, P42 is not in use at the moment and P43 is Z axis.

And config file is now:

; Configuration file for Duet 3 (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.10 on Thu Feb 24 2022 09:21:45 GMT+0100 (hora estándar de Europa central) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Atarfil" ; set printer name M575 P1 S1 B57600 ; Wait a moment for the CAN expansion boards to start G4 S2 ; Network M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P40.0 S0 R0 T5:5:10:10 ; physical drive 121.0 goes forwards M569 P41.0 S1 R0 T5:5:10:10 ; physical drive 122.0 goes forwards M569 P42.0 S1 R0 T5:5:10:10 ; physical drive 123.0 goes forwards M569 P43.0 S1 R0 T5:5:10:10 ; physical drive 124.0 goes forwards M569 P0 S0 R0 ; R0 MODIFICACION M584 X40.0 M584 Y41.0 M584 Z42.0 M584 Z43.0 M584 E0 ; set drive mapping M350 X11.11 Y6.25 Z10 E16 I1 ; configure microstepping with interpolation M92 X11.11 Y6.15 Z200 E600 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z100.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z10.00 E250.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E1680 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X2200 Y200 Z70 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin 121.io0.in M574 Y1 S1 P"io2.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin 122.io0.in M574 Z1 S1 P"io3.in+io4.in" ; configure switch-type (e.g. microswitch) endstop for low end on Z via pin 123.io0.in ; configure switch-type (e.g. microswitch) endstop for low end on Z via pin 123.io0.in ; Z-Probe M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed M557 X15:215 Y15:195 S20 ; define mesh grid ; Heaters M308 S0 P"temp3" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"out0" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 A340 C2745.9 D25 S1.00 B0 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"out1" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 R1.278 C282.5 D6.68 S1.00 V23.1 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; Fans M950 F0 C"out5" Q500 ; create fan 0 on pin out4 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"out4" Q500 ; create fan 1 on pin out5 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools ;M563 P0 S”v4” D0 H1 ; Define tool 0 M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

@dc42 we have a person now checking all mechanics in case there's some problem with it also.

-

@createc3d another test you can do is to approach a particular point (say X=100) from one direction (e.g. from X50) and then from the other (e.g. X150) and check whether the print head goes to exactly the same place in both cases.

-

@dc42 I'm going to tell the people with the machine to do this test, but I think in linear movement the machine has no problem.

About the information before, why is different the step timming in the drivers if we have in config.g the same for all of them?

-

@dc42 this test was fine... but we tried to print two lines, one with 45 degrees and other with 3 degrees... the 45º line was drawn ok, but the 3º line the machine only moves in X axis... the Y was not moving... any ideas?