1HCL 1.0 closed loop controller

-

@phaedrux is the diagnostic light rite next to the micro USB port?

-

@phaedrux

OK I used BOSSA to install Duet3Firmware_MB6HC... not Duet2and3Firmware-3.4.0 and it worked... I have access to DWC... so is it at this point I can install Duet2and3Firmware-3.4.0 or is there something else I should do to make sure I don't have another system lock up.

OK I used BOSSA to install Duet3Firmware_MB6HC... not Duet2and3Firmware-3.4.0 and it worked... I have access to DWC... so is it at this point I can install Duet2and3Firmware-3.4.0 or is there something else I should do to make sure I don't have another system lock up. -

If you now have access to DWC you can upload the full 3.4 zip file to ensure you have all the right files in place for future updates.

https://github.com/Duet3D/RepRapFirmware/releases/download/3.4.0/Duet2and3Firmware-3.4.0.zip

Upload that zip file as is to the system tab in DWC. Don't extract it first. Once done, check the firmware version again with M115. It may prompt to update any attached expansion boards as well. You can check those with M115 B# where # is the CAN bus address of the expansion board.

-

Same errors as before, it is Duet2and3Firmware-3.4.0 causing the system to lock up, I'm going to start over here, this next time I will record and post a youtube video of the update as it happens. Hopefully I can glean some idea as to why or when exactly the fail happens. unless you have a better idea?

-

@phaedrux do you think it would help to disconnect everything from the board except the panel Due?

-

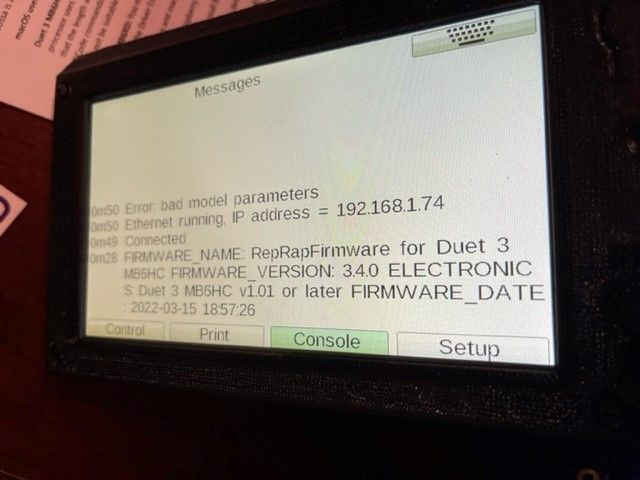

@phaedrux I erased the board again and then used BOSSA to re-install Duet3Firmware_MB6HC.bin. At startup the first error I get on my panel due is "ERROR Bad model parameters". Then it posts the IP address and then it posts connected.

-

@supertb1 said in 1HCL 1.0 closed loop controller:

At startup the first error I get on my panel due is "ERROR Bad model parameters".

That suggests a problem with one of your M307 commands in config.g, or a missing M307 command.

-

@dc42 ; General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Hemera" ; set printer name; Network

M552 P192.168.1.74 S1 ; enable network and acquire dynamic address via DHCP

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

G4 S1 ;wait for expansion boards to start

M569.1 P50.0 T2 C5 E5:10 ; Configure the 1HCL board at CAN address 50 with a quadrature encoder on the motor shaft that has 20 steps per motor full step.

M569.1 P51.0 T2 C5 E5:10 ; Configure the 1HCL board at CAN address 51 with a quadrature encoder on the motor shaft that has 20 steps per motor full step.

M569 P50.0 D4 S1 ; Configure the motor on the 1HCL at can address 50 as being in closed-loop drive mode (D4), Open loop (D2) and not reversed (S1) X axis

M569 P51.0 D4 S1 ; Configure the motor on the 1HCL at can address 51 as being in closed-loop drive mode (D4), Open loop (D2) and not reversed (S1) Y axis

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M584 X50.0 Y51.0 Z0.0 E0.1 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X106.50 Y106.50 Z400.00 E420.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X1000 Y1000 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

M917 X10 Y10 ; Set the closed loop axes to have a holding current of zero; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X235 Y235 Z235 S0 ; set axis maxima; Endstops

M574 X1 S1 P"io1.in" ; configure active-high endstop for low end on X via pin !^io1.in

M574 Y1 S1 P"io2.in" ; configure active-high endstop for low end on Y via pin !^io2.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

M591 D0 P7 C"io5.in" L7 R55:150 E22 S1 ;Bigtree smart filament moniter v2 set to moniter between 55%-150% of 7 counts over a distance of 22mm; Z-Probe

M950 S0 C"io7.out" ; create servo pin 0 for BLTouch

M558 P9 C"io7.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X60 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 X15:200 Y15:200 S20 ; define mesh grid; Heaters

M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 Bed Heater

M950 H0 C"out1" T0 ; create bed heater output on out1 and map it to sensor 0

M307 H0 B1 S5.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"temp1" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp1

M950 H1 C"out2" T1 ; create nozzle heater output on out2 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M950 F0 C"out8" Q500 ; create fan 0 on pin out8 and set its frequency

M106 P0 C"Tool Fan" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off

;M950 F1 C"out6" Q500 ; create fan 1 on pin out6 and set its frequency

M950 F1 C"!out6+out6.tach" ; Fan 1 uses out6, but we are using a PWM fan so the output needs to be inverted, and using out6.tach as a tacho input

M950 F2 C"out7" Q500 ; create fan 2 on pin out7 and set its frequency

M106 P1 C"Extruder" S1 H1 T50 ; set fan 1 name and value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

@supertb1 looks like you haven't run M303 heater tuning on either of your heaters, so you have incomplete M307 commands.

-

@dc42 OK thanks... I will get that done... any idea why Duet2and3Firmware-3.4.0 is causing the board to lock up? or do you think the heater tune is the answer?

-

@dc42 This is what I came up with on my heater calibrations:

M307 H0 R0.395 K0.368:0.000 D5.05 E1.35 S1.00 B0

M307 H1 R4.905 K0.241:0.035 D7.64 E1.35 S1.00 B0 V24.0

Do I try and perform Duet2and3Firmware-3.4.0.zip again? or is there something else I need to do? -

@supertb1 said in 1HCL 1.0 closed loop controller:

Do I try and perform Duet2and3Firmware-3.4.0.zip again? or is there something else I need to do?

Just to verify, you are uploading the whole zip file to the system tab in DWC? Correct?

Can you send M122 and M98 P"config.g" in the gcode console and copy and paste the results here?

Are you using a raspberry pi?

-

@phaedrux

To answer your question I am using the DWC to upload the Zip file as is with out unziping it in any way and no there is no Raspberry Pi or any other kind of USB handler. It is strictly Duet equipment in a stand alone format in the control box. Incedently I did get a good response back on the Y axis in closed loop so I am excited to get to that part. Let me know your thoughts please.

M122

=== Diagnostics ===

RepRapFirmware for Duet 3 MB6HC version 3.4.0 (2022-03-15 18:57:24) running on Duet 3 MB6HC v1.01 or later (standalone mode)

Board ID: 08DJM-956BA-NA3TJ-6J9F2-3SD6J-9B9AT

Used output buffers: 1 of 40 (13 max)

=== RTOS ===

Static ram: 151000

Dynamic ram: 96256 of which 0 recycled

Never used RAM 103416, free system stack 200 words

Tasks: NETWORK(ready,25.4%,237) ETHERNET(notifyWait,0.0%,184) HEAT(notifyWait,0.0%,321) Move(notifyWait,0.0%,352) CanReceiv(notifyWait,0.0%,797) CanSender(notifyWait,0.0%,374) CanClock(delaying,0.0%,339) TMC(notifyWait,8.0%,92) MAIN(running,66.4%,1101) IDLE(ready,0.1%,30), total 100.0%

Owned mutexes:

=== Platform ===

Last reset 00:01:45 ago, cause: power up

Last software reset at 2022-04-19 16:25, reason: User, GCodes spinning, available RAM 103216, slot 2

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

Aux0 errors 0,0,0

Step timer max interval 127

MCU temperature: min 19.7, current 30.8, max 31.0

Supply voltage: min 24.2, current 24.2, max 24.3, under voltage events: 0, over voltage events: 0, power good: yes

12V rail voltage: min 12.0, current 12.1, max 12.2, under voltage events: 0

Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0

Events: 0 queued, 0 completed

Driver 0: standstill, SG min 0, mspos 8, reads 59917, writes 14 timeouts 0

Driver 1: standstill, SG min 0, mspos 8, reads 59917, writes 14 timeouts 0

Driver 2: standstill, SG min 0, mspos 8, reads 59920, writes 11 timeouts 0

Driver 3: standstill, SG min 0, mspos 8, reads 59920, writes 11 timeouts 0

Driver 4: standstill, SG min 0, mspos 8, reads 59920, writes 11 timeouts 0

Driver 5: standstill, SG min 0, mspos 8, reads 59921, writes 11 timeouts 0

Date/time: 2022-04-19 20:48:29

Slowest loop: 2.39ms; fastest: 0.05ms

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 25.0MBytes/sec

SD card longest read time 1.5ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 125, segments created 0, maxWait 0ms, bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty

=== Filament sensors ===

Extruder 0 sensor: no data received

=== CAN ===

Messages queued 957, received 1698, lost 0, boc 0

Longest wait 6ms for reply type 6018, peak Tx sync delay 6, free buffers 50 (min 49), ts 526/525/0

Tx timeouts 0,0,0,0,0,0

=== Network ===

Slowest loop: 4.39ms; fastest: 0.02ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions Telnet(0), 0 sessions

HTTP sessions: 1 of 8-

Ethernet -

State: active

Error counts: 0 0 1 0 0

Socket states: 5 2 2 2 2 0 0 0M98 P"config.g"

HTTP is enabled on port 80

FTP is disabled

TELNET is disabled

M122 B50.0

Diagnostics for board 50:

Duet EXP1HCL firmware version 3.4.0 (2022-03-15 08:58:59)

Bootloader ID: SAME5x bootloader version 2.4 (2021-12-10)

All averaging filters OK

Never used RAM 52288, free system stack 192 words

Tasks: Move(notifyWait,0.0%,152) HEAT(notifyWait,0.0%,88) CanAsync(notifyWait,0.0%,70) CanRecv(notifyWait,0.0%,79) CanClock(notifyWait,0.0%,72) TMC(notifyWait,34.6%,360) CLSend(notifyWait,0.0%,152) MAIN(running,63.7%,407) IDLE(ready,0.0%,30) AIN(notifyWait,1.7%,265), total 100.0%

Last reset 00:04:37 ago, cause: power up

Last software reset data not available

Closed loop enabled: yes, pre-error threshold: 5.00, error threshold: 10.00, encoder type rotaryQuadrature, reverse polarity: no, position 1, raw count = 0, tuning mode: 0, tuning error: 0x1, collecting data: no

Control loop runtime (ms): min=0.003, max=0.012, frequency (Hz): min=11364, max=17045

Driver 0: pos 0, 106.5 steps/mm,not tuned, SG min 0, mspos 8, reads 2343, writes 34 timeouts 0, steps req 0 done 0

Moves scheduled 0, completed 0, in progress 0, hiccups 0, step errors 0, maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0

Peak sync jitter -7/7, peak Rx sync delay 195, resyncs 0/0, no step interrupt scheduled

VIN voltage: min 24.3, current 24.3, max 24.4

V12 voltage: min 12.1, current 12.1, max 12.1

MCU temperature: min 22.7C, current 25.6C, max 25.8C

Last sensors broadcast 0x00000000 found 0 45 ticks ago, 0 ordering errs, loop time 0

CAN messages queued 2258, send timeouts 0, received 2511, lost 0, free buffers 37, min 37, error reg 0

dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 0M122 B51.0

Diagnostics for board 51:

Duet EXP1HCL firmware version 3.4.0 (2022-03-15 08:58:59)

Bootloader ID: SAME5x bootloader version 2.4 (2021-12-10)

All averaging filters OK

Never used RAM 52288, free system stack 182 words

Tasks: Move(notifyWait,0.0%,152) HEAT(notifyWait,0.0%,88) CanAsync(notifyWait,0.0%,70) CanRecv(notifyWait,0.0%,79) CanClock(notifyWait,0.0%,72) TMC(notifyWait,34.6%,360) CLSend(notifyWait,0.0%,152) MAIN(running,63.7%,417) IDLE(ready,0.0%,30) AIN(notifyWait,1.7%,265), total 100.0%

Last reset 00:05:21 ago, cause: power up

Last software reset data not available

Closed loop enabled: yes, pre-error threshold: 5.00, error threshold: 10.00, encoder type rotaryQuadrature, reverse polarity: no, position 1, raw count = 0, tuning mode: 0, tuning error: 0x1, collecting data: no

Control loop runtime (ms): min=0.003, max=0.011, frequency (Hz): min=11364, max=17442

Driver 0: pos 0, 106.5 steps/mm,not tuned, SG min 0, mspos 8, reads 655, writes 34 timeouts 0, steps req 0 done 0

Moves scheduled 0, completed 0, in progress 0, hiccups 0, step errors 0, maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0

Peak sync jitter -4/4, peak Rx sync delay 195, resyncs 0/0, no step interrupt scheduled

VIN voltage: min 24.3, current 24.3, max 24.4

V12 voltage: min 12.2, current 12.2, max 12.2

MCU temperature: min 22.1C, current 25.8C, max 25.8C

Last sensors broadcast 0x00000000 found 0 140 ticks ago, 0 ordering errs, loop time 0

CAN messages queued 2610, send timeouts 0, received 2909, lost 0, free buffers 37, min 37, error reg 0

dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 0 -

-

At least it looks like all of the boards are up to date now, so it did apply the firmware.

It may help to see a video of the entire firmware zip file upload process so we can see what it's doing along the way.

-

@phaedrux https://www.youtube.com/watch?v=N9KXrUuBpnk

It took this time... thank god... ok so I tried to home my "X" axis in closed loop and it failed to home properly. The console reports:

4/20/2022, 3:31:42 PM Error: Driver 50.0 error: failed to maintain position

4/20/2022, 3:31:41 PM Warning: Driver 50.0 warning: tuning failed

Warning: Driver 50.0 new tuning error(s): The measured motion was inconsistent.

4/20/2022, 3:31:40 PM Error: Driver 50.0 error: failed to maintain position

4/20/2022, 3:31:37 PM Error: Driver 50.0 error: failed to maintain position

Error: Driver 50.0 error: failed to maintain position -

@phaedrux Y axis and Z axis home fine

Here is my HomeX:

M569 P50.0 D0 ; Turn off closed loopG91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X-240 F3000 ; move quickly to X axis endstop and stop there (first pass)

G1 H2 X5 F6000 ; go back a few mm

G1 H1 X-240 F240 ; move slowly to X axis endstop once more (second pass)G90 ; absolute positioning

G1 X50 F3000 ; Move to a known-safe position

M400 ; Wait for the move to complete

G4 P500 ; Wait for the motor to settle

M569 P50.0 D4 ; Turn closed loop back on

M569.6 P50.0 V31 ; Perform the tuning manoeuvres for a quadrature encoder

G1 X0 ; Move back to X0G1 H2 Z0 F6000 ; lower Z again

-

Glad it worked this time. Hopefully that means everything is up to date and in sync now and should stay that way going forward.

As for the homing and closed loop, I'm not really familiar. Best I can do is point you to the M569.x gcode command documentation here:

https://docs.duet3d.com/User_manual/Reference/Gcodes#m5696-execute-closed-loop-tuning-move

Let me know how you proceed and we can figure it out.

-

@dc42 In open loop what would cause the 1HCL board to report a failed to maintain position on a homing sequence? As soon as I move the axis it makes the same report, as soon as I restart the main board it makes that report

-

@supertb1 are you sure that the driver is in open loop mode? Try using D2 instead of D0 in the M569 command to set the driver to open loop mode.

-

@dc42 Yes sir, that is how it is set at the moment, would resetting the board help?

; Drives

G4 S1 ;wait for expansion boards to start

M569.1 P50.0 T2 C5 E5:10 ; Configure the 1HCL board at CAN address 50 with a quadrature encoder on the motor shaft that has 20 steps per motor full step.

M569.1 P51.0 T2 C5 E5:10 ; Configure the 1HCL board at CAN address 51 with a quadrature encoder on the motor shaft that has 20 steps per motor full step.

M569 P50.0 D2 S1 ; Configure the motor on the 1HCL at can address 50 as being in closed-loop drive mode (D4), Open loop (D2) and not reversed (S1) X axis

M569 P51.0 D4 S1 ; Configure the motor on the 1HCL at can address 51 as being in closed-loop drive mode (D4), Open loop (D2) and not reversed (S1) Y axis

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M584 X50.0 Y51.0 Z0.0 E0.1 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.50 Y81.70 Z407.00 E420.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X1000 Y1000 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

M917 X100 Y100 ; Set the closed loop axes to have a holding current of zero; homex.g

; called to home the X axis

;

; generated by RepRapFirmware Configuration Tool v3.3.10 on Fri Apr 08 2022 20:56:07 GMT-0500 (Central Daylight Time)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X-240 F1800 ; move quickly to X axis endstop and stop there (first pass)

G1 H2 X5 F6000 ; go back a few mm

G1 H1 X-240 F360 ; move slowly to X axis endstop once more (second pass)

G1 H2 Z-5 F6000 ; lower Z again

G90 ; absolute positioning

; homex.g