Solved: Jogging past axis limits..?

-

Here you go, @jay_s_uk...

(I'd like to know how to do this with the colourful screens others use...); General preferences

M453 ; set machine to CNC mode

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Heretic" ; set printer name; Network

M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Configure Drives

M569 P0.0 S0 ; physical drive 0.0 goes backwards - X axis

M569 P0.1 S1 ; physical drive 0.1 goes forwards - Y1 axis

M569 P0.2 S1 ; physical drive 0.2 goes forwards - Y2 axis

M569 P0.3 S0 ; physical drive 0.3 goes backwards - Z axis

M584 X0.0 Y0.1:0.2 Z0.3 ; set drive mapping; Configure Motors

M350 X16 Y16 Z16 I1 ; configure microstepping with interpolation

M92 X400 Y400 Z400 ; set steps per mm

M566 X500 Y500 Z500 ; set maximum instantaneous speed changes (mm/min)

M203 X2500 Y2500 Z2500 ; set maximum speeds (mm/min)

M201 X150 Y150 Z150 ; set accelerations (mm/s^2)

M906 X2400 Y2400 Z 2400 ; set motor currents (mA) 80% of maximum (3000mA)

M84 S0 ; Disable motor idle current reduction; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X549 Y787 Z100 S0 ; set axis maxima

; M208 X0:535 Y0:787 Z0:100 S0 ; set axis minima and maxima; Endstops

M574 X1 S1 P"io8.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin io8.in

M574 Y1 S1 P"io6.in+io3.in" ; configure switch-type (e.g. microswitch) and dual self-squaring high ends on Y1 via pin io6.in and on Y2 via pin io3.in

M574 Z1 S1 P"io2.in" ; configure switch-type (e.g. microswitch) endstop for low end on Z via pin io2.in; Fans

M950 F0 C"out8" Q500 ; create fan 0 on pin out 8 and set its frequency

M106 P0 S0.5 H-1 ; set fan 0 value. Thermostatic control is turned off; Makita and relay configuration

M950 R0 C"out1+out7" ; enable router relay on out8

M563 P0 S"Makita" R0 ; assign spindle 0 to tool 0 and name it Makita

T0 ; select tool 0; Custom settings are not defined

; Miscellaneous

M564 S1 H1 ; Disable jog commands when not homed...and the Homeall file, too...

G91 ; relative positioning

G1 H1 Z100 F2400 ; move quickly to the Z axis endstop (first pass)

G1 H2 Z-5 F2400 ; go back 5mm

G1 H1 Z100 F240 ; move slowly to the Z axis endstop (second pass)

G1 H2 Z-3 F240 ; go back 3mm

G1 H1 X549 Y787 F2400 ; move quickly to X and Y axis endstops (first pass)

G1 H2 X-5 Y-5 F2400 ; go back 5mm

G1 H1 X549 Y787 F240 ; move slowly to X and Y axis endstops (second pass)

G1 H2 X-3 Y-3 F240 ; go back 3mm

G90 ; absolute positioning -

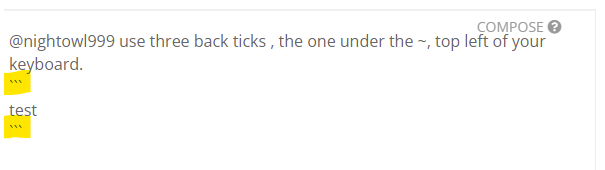

@nightowl999

do you have and H564 statements in your homing macros ?formating: use three back ticks , the one under the ~, top left of your keyboard.

test

-

Forgive me, @sinned6915, but I'm not really sure what you mean, but I don't have H564 statements in the homing files. I do have them in the config.g file, though (M564 S1 H1)

-

@nightowl999 both your X and y endstop locations are set to the minima (

X1andY1). When you home, the minima limit from M208 is applied even though you're moving to the Maxima.

Change the 1 to a 2 (soX2Y2) in yourM574 -

There is definitely something wrong with the configuration files of my machine.

As I understand it, M564 is used to limit (or not) axis movements, with the S limiting (or not) movement outside the axis boundaries and H to allow (or not) moving the axes without homing.

In my config.g file (above) there is the line "M564 S1 H1" and, when I first start up the machine, I can't move an axis without homing it first, as I would expect (and I get the G0/G1: insufficient axes homed error).

If I then send M564 H0 S1, I can move any axes in any direction, but also past it's limits, which I thought the S1 would prevent.

Am I going mad?

-

I did that, @jay_s_uk, but then the endstops didn't activate, but I'll try (anything) again!

UPDATE: Now I get the G0/G1: target position outside machine limits when I try to move any axis. The proximity sensors do work, though!

-

@nightowl999 you'll need to do the same with your Z endstop too.

There's also no need to include M564 as S1 H1 are the default setup -

I'm in the process of doing that now, @jay_s_uk, but won't I still have the same problem?

-

@nightowl999 not if you're jogging to the -ve once homed

-

Blinkin' 'eck, @jay_s_uk, you've only gone and sorted it!

The only thing, and I might just have to get used to this, is that the machine home coordinates are back to the maxima values, rather than 0, 0, 0 I was hoping to achieve.

I don't care any more

. It's not as if the machine co-ordinates really matter with a CNC, as the starting point of the work being cut is more important!

. It's not as if the machine co-ordinates really matter with a CNC, as the starting point of the work being cut is more important! -

@nightowl999 exactly. Typically front left is 0,0. Ideally you want it there as otherwise whatever you're cutting is the opposite way it appears on screen.

Homing to max is perfectly fine.

If you did want to flip it the other way you'd have to change your M574s back, flip the move direction in M569 and rewrite your homing files to move towards the minima rather than the maxima -

Thanks, @jay_s_uk. I think it's time I started doing stuff, rather than messing about!

Talking of homing... Because I can't really reach the back of the machine when it's homed, I temporarily REM'd out the lines relating to the Y axes in the homeall.g file. But, it still homed the Y axes.

Does the Home All button on the dashboard run the homeall.g file, or the individual home files?

-

@nightowl999 homeall but if a certain axis isn't there, it then calls the homing file for that axis, unless they're hidden

-

Well, I don't know who had that foresight, @jay_s_uk, but that would explain the magical event

I really appreciate the help, thank you.

-

@nightowl999 said in Solved: Jogging past axis limits..?:

I think it's time I started doing stuff, rather than messing about!

That will leave a bruise if your don't sort this out!

Did you follow the basic comissioning procedure that it outlined in the docs?

https://docs.duet3d.com/en/How_to_guides/Commissioning#h-7-check-endstops

Its really straight forward to to take it step by stepIf you do it 'half-way' then it WILL come back to haunt you someday. DAMHIKT!

-

@sinned6915 said in Solved: Jogging past axis limits..?:

That will leave a bruise if your don't sort this out!

Did you follow the basic comissioning procedure that it outlined in the docs?

https://docs.duet3d.com/en/How_to_guides/Commissioning#h-7-check-endstops

Its really straight forward to to take it step by stepIf you do it 'half-way' then it WILL come back to haunt you someday. DAMHIKT!

Yeah, I followed those instructions closely, but it's in changing things to suit my situation that made it difficult (in my mind, anyway), and trying to keep track of incremental changes is a bit challenging.

I believe this is sorted now, so apart from one or two other capabilities I want to integrate into the system (using an old Carbide3D touch probe, install a power fail/resurrect ability and install an externally switched feed hold (pause/resume) facility, I'm almost ready to cut stuff!

-

@nightowl999 said in Solved: Jogging past axis limits..?:

Carbide3D

I am in the middle of comissioning a mill right now too. I understand what you are going through.

GOOD LUCK!

-

@nightowl999 said in Solved: Jogging past axis limits..?:

I believe this is sorted now, so apart from one or two other capabilities I want to integrate into the system (using an old Carbide3D touch probe, install a power fail/resurrect ability and install an externally switched feed hold (pause/resume) facility, I'm almost ready to cut stuff!

Would you post a picture or two of your mill?

Thanks.

Frederick

-

Sure, @fcwilt, but I’ll do it tomorrow 🥱

-

Not sure if this is what you wanted, @fcwilt, but here you go:

The machine is a RatRig 1075 KillerBee, although I've made a few amendments to the supplied machine, including using 4x proximity sensors instead of limit switches, and redesigned the spoil board supports. It has a Duet 3 MB6HC control board (as you already know!) connected via a wired network to a Microsoft Surface Pro.

Most of my work is done on my iMac, which is in the house, so I connect to the Surface Pro and the Duet via a wired network using powerline adapters.

Apart from my own knowledge limits, everything seems to work well - but the proof will be when I eventually make something!