2 Thermistors in bed

-

I have two thermistors to monitor my bed temp. the Main Thermistor centered on the heating pad. and also a 2nd one mounted to one corner of the bed. my bed is quite thick (1/2 alum) so it takes time for the heat to soak in, generally when I warm up my bed to 65 degrees i will watch the bed thermistor hit that temp fairly quickly but I will wait until the 2nd thermistor hits that temp 5-10min later. before I start my print. anyways is there a way to set it so my print wont start until the 2nd thermistor is at bed temp.

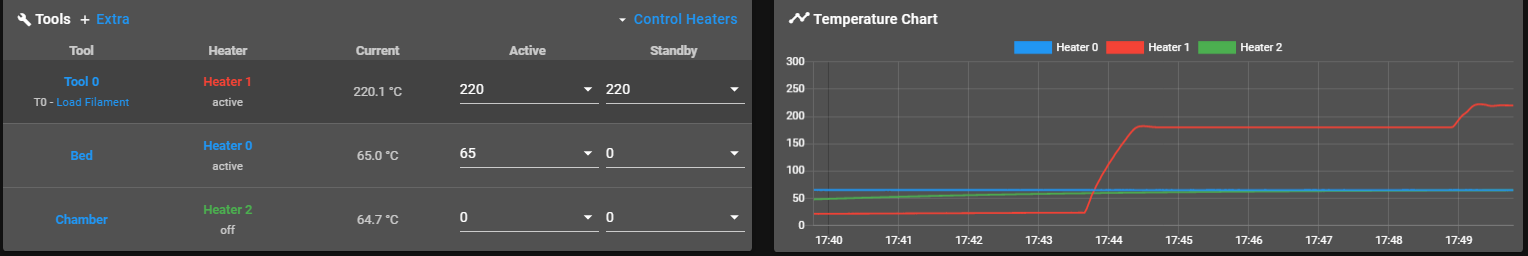

FYI. I set my 2nd therm. to be called Chamber for now

-

Not an answer to your question, but I'm curious how big your print-bed is? I'm planning on around 18" x 18", and I'm thinking 3/8" thick will be good so it won't warp.

-

@adamfilip Here is one way that I use in my pre-print macro - there may be other ways too.

while sensors.analog[0].lastReading < 75 ; M291 P"Waiting for bed to pre-heat to 75" R"Pre-Print Macro" echo "Bed", sensors.analog[0].lastReading G4 S5Substitute your own sensor number and the temperature that you want. The M291 and "echo" are optional but I like to know what's going on.....

EDIT. BTW, I found that having a sensor at the junction between a heater and a thick aluminium plate is a bad idea. What happens is (as you have observed) the temperature at that point rises rapidly. When it hits (or gets close to) the set point, the heater turns off even though the upper surface is still cool. You then have to wait for the temperature at the junction to drop before the heater turns on and so the process repeats until eventually the upper surface gets close to the desired temperature. The net result is that it takes an awfully long time for the build surface to get hot enough (due to the constant on-off cycling of the heater). To mitigate that. I drilled small hole in the edge of the plate, as deep as possible and close to the upper surface as possible and installed the sensor in that hole. This reduced the warm up time by more than 50% and negates the need for the second sensor.

-

@adamfilip As an addition to the wise words of @deckingman: if you follow his advice, you can use the thermistor built into the heater to limit its maximum temperature with M143. Adapt the first example given there to your own requirements:

M143 H1 P0 S275 A2 ; switch off heater 1 temporarily if it exceeds 275°C