Problem with toolpath not cutting correctly.

-

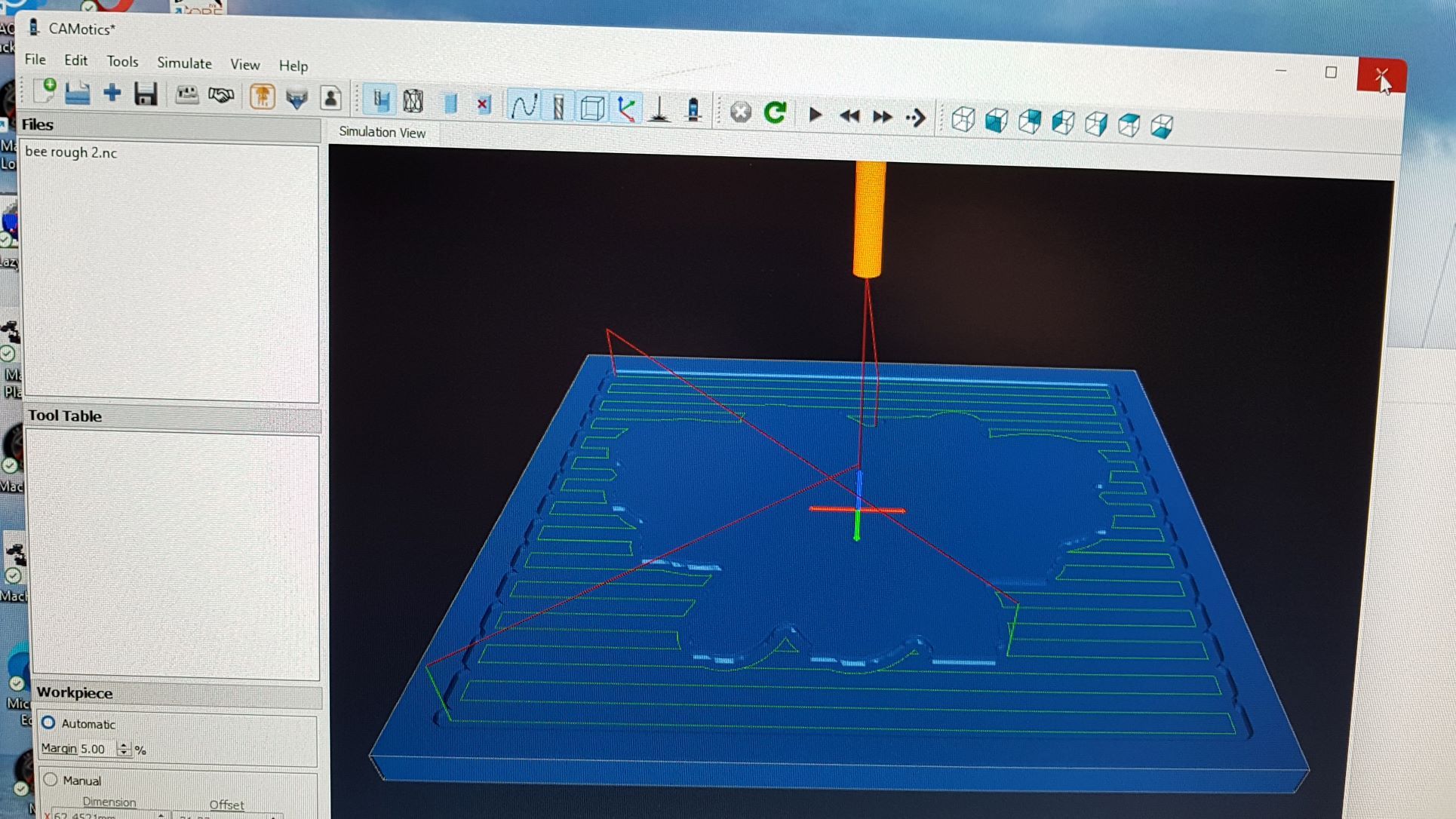

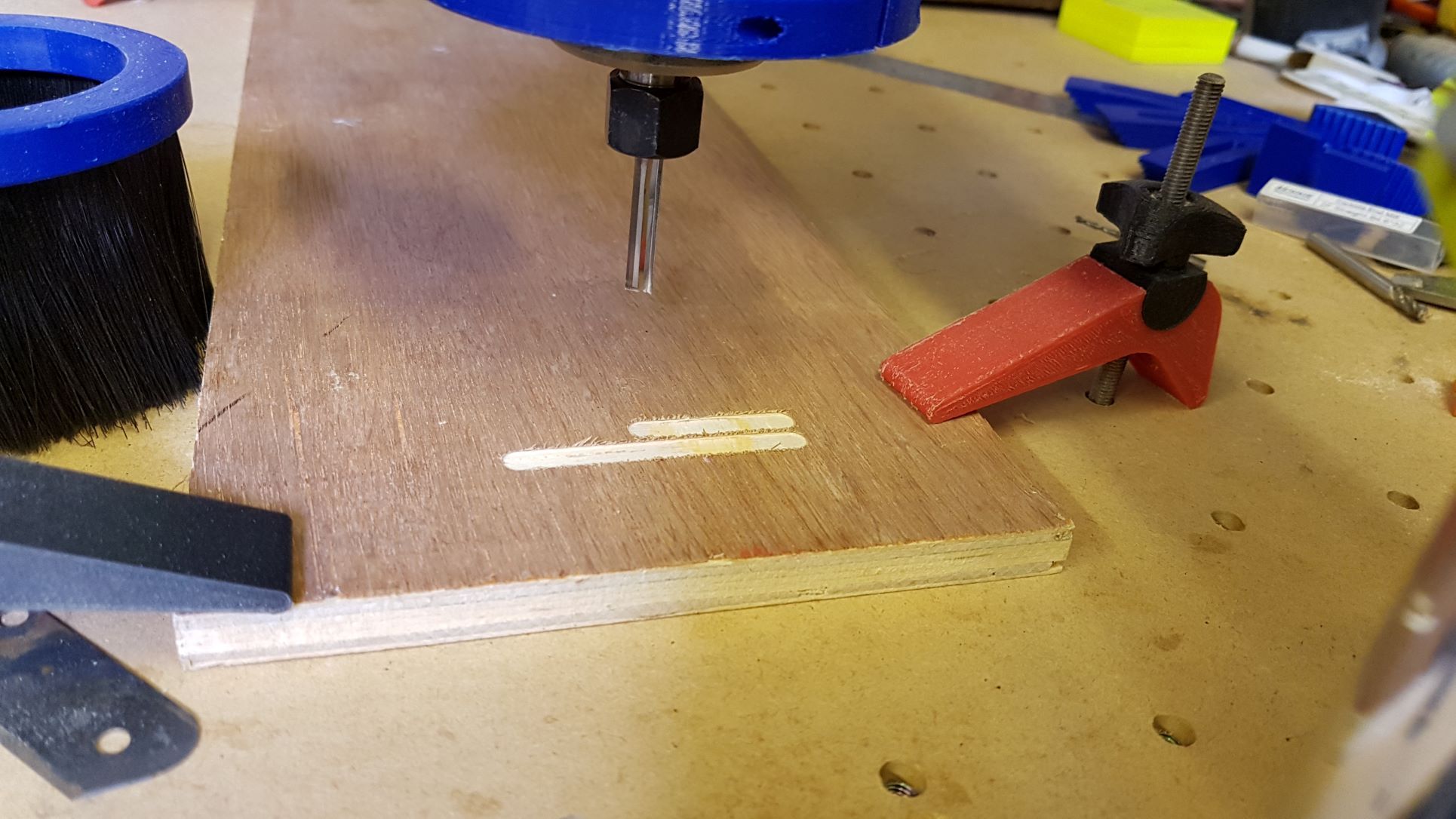

Hi, I’m using Workbee software on a Duet2 Wifi controlling an MPCNC machine. I have a problem in that for some reason the roughing toolpaths I produce using Artcam 2018 do not cut properly. The finishing toolpaths using the ‘spiral in a box’ setting work fine but all the roughing toolpaths, whether raster or offset, fail. I have attached the toolpaths together with an image of the roughing toolpath run in Camotics simulator and a photo of the actual cutting done on my machine from the same file. The machine runs along each of the two paths it cuts 8 or 9 times... I would be delighted if someone could give me a clue as to what is going wrong here. Thanks.

bee rough 2.pdf

bee finish.pdf

-

This post is deleted! -

@ian-0 At a guess, I'd say that the machine is skipping steps on the 'roughing' cut, where speed is set to F6000 (line 23 in your 'bee rough 2.pdf' Gcode file is

N23 G1 X27.3873 F6000.0). This is 100mm/s - I'd say that is very fast, even for a roughing cut, and all cuts are in X and Y axes. The 'finishing' cut is running at F3600 (line 22 in 'bee finish.pdf isN22 G1 X0.0208 Y0.0361 Z-0.4571 F3600.0), which is 60mm/s - also fast, especially for a finishing cut I would have thought. Each line does have a Z axis movement, which may be slowing the move down though; if you watch DWC when running this file, it should show the requested speed and actual speed.Test whether your machine can actually move at 100mm/s. Send Gcode, starting from X0 Y0, something like

G1 X100 Y100 F6000. DWC should report if the move is completed, then check if the machine has actually moved that far. You may need to make an actual cut, to see if the machine has the power to move at this speed, which does seem very fast for cutting.If it doesn't do the move correctly, there are a number of possibilities why not:

- Just cutting too fast (fix: reduce speed in Gcode generator or limit axis speed in config.g)

- Motors not strong enough to move axes at that speed while cutting, if this is the intended speed (fix: motor current may be set too low, but CAUTION: don't just increase current! Check motor specification)

- Axes binding (fix: check axes for squareness and smooth, unhindered movement, check rails are straight, lubricate etc.)

Post your config.g if you continue to have problems, and response to M122.

(Another) Ian (there are so few of us, except hurricanes!)

-

@ian-0 Hi, I don't think it's skipping steps. That would produce some of the desired path.

I'm not entirely clear on what it's actually doing. Are you saying that it cuts the two grooves we see then comes back and cuts them again and again and then it stops? That would be bizarre. It could be that it's deciding the cnc hasn't parsed those two chunks and it sends them repeatedly until it gives up I suppose.

I'd also vote for seeing your config.g file for RRF.

One simple test you could do is manually move the CNC head - following along the G-code roughing file - just send each line individually in the console, except the Z offset, (without the N prefix) and see how the head moves.

mark