Can cables and external stepper

-

Hi,

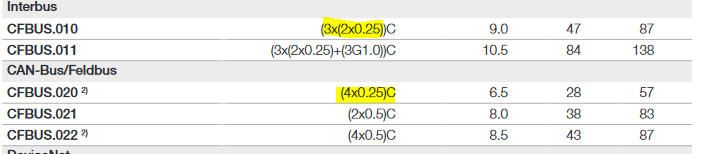

I'm converting an existing 3D printer (Creatbot D600 Pro) to a Duet 3.

I need some help regarding CAN connections.I have one Duet3, three 1XD expansion Board (for external steppers), one distribution toolboard and one toolboard (for now)

A - For the connection to the distribution toolboard, i have no problem, i will use the included RJ11 cable.

B - For the connection to the 1XD expansion Board and between them, I wanted to do some custom RJ11 cables as I could not find them in small size.

I bought some RJ11 cables but they are not twisted pairs (see attached picture)Is it okay to use non twisted pair cables for short distances (less than 15cm) ?

C - For the connection from the distribution toolboard to the tool, I need to solder to the connector or crimp my own.

Regarding the rest of the cable, what would be the best option ?

1 - Using one of the RJ11 cables which is not made with twisted pair

2 - Just take 4 cables and twist two pairs of them myself, what AWG should I take for this ?

3 - both options are bad and I should just order twisted pair cables (which I did, but Farnell then said they will arrive in March 2023...). It's a pain for me to order things (except from Farnell), so I would rather avoid ordering from other supplier.

The cable need to be around 3m long.Also, why do I need 4 cables for this Can connection and not only 2 ?

If it is at the end of the CAN line I can use only 2 no ?Final question, I will be using external stepper, i searched through this page and found no information about this :

Do I need to set the microsteping used on my external stepper in my config.g (M350) ?

What do I need to put inside the Motor currents command (M906) ?Here is the start of my config.g for reference.

It's not finished as I need to add fans, create tools, and PID tune commands.;######################## ; General preferences ;######################## M111 S0 ; Debugging off G21 ; Work in millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M555 P2 ; Set firmware compatibility to look like Marlin M667 S1 ; Select CoreXY mode ;######################## ; Network ;######################## M550 P"Creatbot" ; Set machine name M553 P255.255.255.0 ; Ethernet Settings - Mask M554 P192.168.1.255 ; Ethernet Settings - Passerelle M552 P192.168.1.12 ; Ethernet Settings - Adresse M552 S1 ; Enable Networking M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Wait a moment for the CAN expansion boards to start G4 S2 ;######################## ; Drive ;######################## ;Drive directions M569 P121 S1 ; Drive on Toolboard (E0) - change to 20 M569 P122 S1 ; Drive on 1XD (X) - change to 40, might need R0/R1 M569 P123 S1 ; Drive on 1XD (Y) - change to 41, might need R0/R1 M569 P124 S1 ; Drive on 1XD (Z) - change to 42, might need R0/R1 ;Drive mapping and control M584 X122 Y123 Z124 E121 ; Stepper motor connection points ;M350 X16 Y16 Z16 I0 ; Configure microstepping without interpolation for XYZ- needed or not ? M350 E16 I1 ; Configure microstepping with interpolation for the extruder M92 X266.67 Y266.67 Z960.00 E392 ; Set steps per mm assuming x16 microstepping ; Axis Limits M208 X0 Y0 Z0 S1 ; Set axis minima - need adjustments M208 X600 Y600 Z600 S0 ; Set axis maxima - need adjustments ;Drive speeds and acceleration M203 X18000 Y18000 Z600 E5000 ; Set maximum speeds (mm/min) M201 X1000.00 Y1000.00 Z100 E2500 ; Set maximum accelerations (mm/s^2) M566 X400 Y400 Z10 E400 ; Set the jerk : maximum instantaneous speed changes (mm/min) ; Motor current M906 X1000 Y1000 Z1000 E1000 I30 ; Set motor currents (mA) and motor idle factor to 30% - needed or not ? M84 S30 ; Set idle timeout ;######################## ; Endstops ;######################## ; Axis Limits M208 X0 Y0 Z0 S1 ; Set axis minima M208 X500 Y500 Z499 S0 ; Set axis maxima ; Endstops M574 X1 S1 P"121.io1.in" ; Set endstop position (X), type (P) and connection point (P) - on toolboard M574 Y1 S1 P"123.io1.in" ; Set endstop position (Y), type (P) and connection point (P) - on 1XD for Y M574 Z1 S1 P"124.io1.in" ; Set endstop position (Z), type (P) and connection point (P) - on 1XD for Z ; Z-Probe M950 S0 C"121.io0.out" ; Create servo pin 0 for BLTouch at connection point (C) M558 P9 C"121.io0.in" H5 F120 T6000 ; Set Z probe type to bltouch (P), the connection point (C), ; the dive height (H), the dive speeds (F), travel speed between probe points (T) G31 P500 X11 Y11 Z1 ; Set Z probe trigger value (P), offset (XY) and trigger height (Z) M557 X40:300 Y40:300 S40 ; define mesh grid ;######################## ; Heaters ;######################## ;Heated bed M308 S0 P"temp0" Y"thermistor" A"Bed" T100000 B3950 ; Set thermistor number (S), connection point (P), name (A) and parameters (YTBC) M950 H0 C"out0" T0 ; Set heater number (H), connection point (C) and map it to a sensor (T) M143 H0 S105 ; Set temperature limit M140 H0 ; Set this heater as bed heater ;Tool M308 S1 P"121.temp0" Y"thermistor" T100000 B4725 C7.06e-8 ; Set thermistor number (S), connection point (P), name (A) and parameters (YTBC) M950 H1 C"121.out0" T1 ; Set heater number (H), connection point (C) and map it to a sensor (T) M143 H1 S285 ; Set temperature limit ;Heated chamber M308 S2 P"temp1" Y"thermistor" T100000 B3950 ; Set thermistor number (S), connection point (P), name (A) and parameters (YTBC) M950 H2 C"out1" T2 ; Set heater number (H), connection point (C) and map it to a sensor (T) M143 H2 S80 ; Set temperature limit M141 H2 ; Set this heater as chamber heater

-

@fbunel said in Can cables and external stepper:

Is it okay to use non twisted pair cables for short distances (less than 15cm) ?

Yes.

Regarding the rest of the cable, what would be the best option ?

1 - Using one of the RJ11 cables which is not made with twisted pair

2 - Just take 4 cables and twist two pairs them myself, what AWG should I take for this ?

3 - both options are bad and I should just order twisted pair cables (which I did, but Farnell then said they will arrive in March 2023...)

The cable need to be around 3m long.For a 3m long cable I recommend you use twisted pair. If you have just one tool board and you put that at the end of the CAN bus, you can run a single twisted pair to it and terminate the bus at the tool board. Recent version tool boards let you do this by adding a solder blob across a pair of pads on the underside of the tool board.

For the cable I usually separate 1 or 2 pairs from a length of SpectraStrip, such as https://www.ebay.co.uk/itm/251792806204. You could also Modbus cable such as https://www.ebay.co.uk/itm/263511046540 but the screen/shield is not needed.

Also, why do I need 4 cables for this Can connection and not only 2 ?

If it is at the end of the CAN line I can use only 2 no ?Yes, see above.

Do I need to set the microsteping used on my external stepper in my config.g (M350) ?

What do I need to put inside the Motor currents command (M906) ?You don't need M350 or M906 commands for external stepper drivers. You may need to use M569 commands with T parameters to set the step and direction pulse timing.

-

First of all, thank you very much for your help @dc42, on this thread and on all the other thread on the forum where I have read you answering to most of my questions.

For a 3m long cable I recommend you use twisted pair. If you have just one tool board and you put that at the end of the CAN bus, you can run a single twisted pair to it and terminate the bus at the tool board. Recent version tool boards let you do this by adding a solder blob across a pair of pads on the underside of the tool board.

For the cable I usually separate 1 or 2 pairs from a length of SpectraStrip, such as https://www.ebay.co.uk/itm/251792806204. You could also Modbus cable such as https://www.ebay.co.uk/itm/263511046540 but the screen/shield is not needed.

Thanks for the additional information.

Can you explain me the difference between buying already twisted cables and taking two unshieldted cable and twisting them together ?Are these reference the correct type of wires ?

https://fr.farnell.com/lapp-kabel/0035800/cable-blinde-2-paires-gris-0-25mm/dp/1491439

https://fr.farnell.com/pro-power/pd1002/cable-7-0-203-blinde-2-paires/dp/1387731

https://fr.farnell.com/van-damme/268202/cable-bleu-series-2paires-par/dp/1891037 -

@fbunel the main things that matter are:

- The cable should be flexible if it has to reach a moving part such as a hot end. So the conductors should be stranded core, not solid.

- The cable impedance should preferably be close to 120 ohms. This is the impedance of CAN termination (Modbus uses the same impedance, which is why Modbus cables are also suitable), Unfortunately the datasheets you linked do don't give the impedance. One of them gives the capacitance and inductance per unit length, from which the impedance can be calculated.

- The loss for signals up to about 10MHz should be low over the distance concerned. This is likely to be the case over 3m for any twisted pair cable you find.

In practice, for a cable length of 3m it's not that critical. Even twisting two single core insulated wires around each other will work.

PS - what sort of cable is normally used in France for connecting a telephone socket to a DSL modem/router?

-

Thanks for the detailed explanation. With your recommendation I checked all the listing of Farnell.

I think I found a winner :

https://fr.farnell.com/lapp-kabel/2170204t/cable-profibus-par-metre/dp/3034318

It's advertised as a BUS Cable with two pairs of stranded core wires and an impedance of 120 ohms.Or this one :

https://fr.farnell.com/belden/9829/cable-blinde-2pair-24awg-gris/dp/1218666

Which has an impedance of 100 ohms, and also stranded core wiresPS - what sort of cable is normally used in France for connecting a telephone socket to a DSL modem/router?

I have no idea. I haven't seen one in ages. Every place I worked/lived in the past 5 years have had optic fiber router.

-

For moving cables, Chainflex series cable from Igus can be found at good prices.

They would be a bit more expensive than usual cables but they may also last longer.

You can find other references (mainly depending on the bend radius) using their configurator : https://chainflex-productfinder.igus.tools/ Select "Can bus" under "system bus" select-boxhttps://www.tme.eu/ is distributing them for non-pro buyers (Not sure you can buy directly from igus as non-pro)

-

@Falcounet

Thanks, the thing is, i'm doing this for my work so I can use a pro account. But buying things at my work is a pain (except from Farnell or RS...) -

@fbunel yes those cables look suitable, although overkill because they are shielded. The Belden one may be more flexible than the Lapp one.

The Chainflex series from IGUS that @Falcounet suggested also look good. You can select "Bus cables" and then "CAN bus".

-

@dc42 @Falcounet

Yes, I found the reference from Chainflex Igus on RS on which I can order easily.

https://uk.rs-online.com/web/p/control-cable/210-0497They seem perfect for the application.

Only problem is that they are not twisted pairs. Do you think this might be an issue ?

I was looking at this one with 4 wires so I can run the Bus IN and Bus OUT in the the same cable.This is probably overkill but this machine will be used intensively so I don't want to cheap out and make sure the cable will hold in time.

Also, I have an additional question, what would be the temperature limit of the toolboard 1LC ?

Will it hold up in an heated enclosure (let's say 70°C, but maybe more) ?

-

@fbunel if the bus goes there-and-back along the same cable then it's not ideal.

Have you considered using one or two pairs from a flexible (not solid core) Ethernet cable?

-

@fbunel The wires are indeed twisted.

You can see it at the product image : https://www.igus.fr/product/1112?artNr=CFBUS.001 -

@dc42

I'm going mad trying to choose cable knowing very well it will probably work fine whatever I choose.Things are :

- I can't order from the internet, only RS and Farnell

- I don't have access to anything that I don't buy. I know it's stupid but I can't take one ethernet cable that is laying around...

- I would like to have it quickly

- I don't have to worry about the money...

- I'd like the right cable for the application.

@Falcounet said in Can cables and external stepper:

@fbunel The wires are indeed twisted.

You can see it at the product image : https://www.igus.fr/product/1112?artNr=CFBUS.001Yes they are twisted but not in two pairs of two I believe. All four are twisted together.

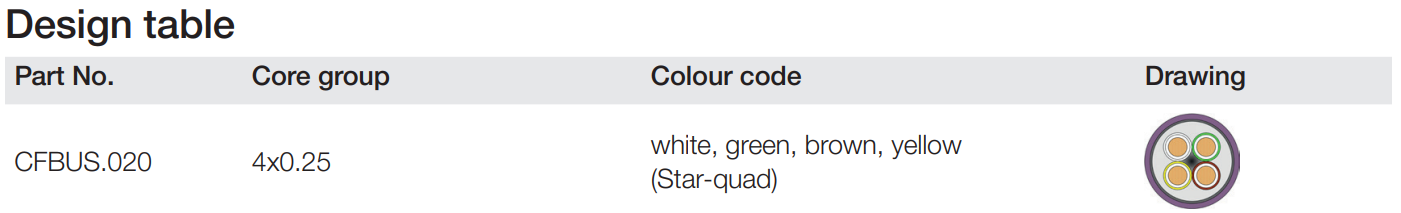

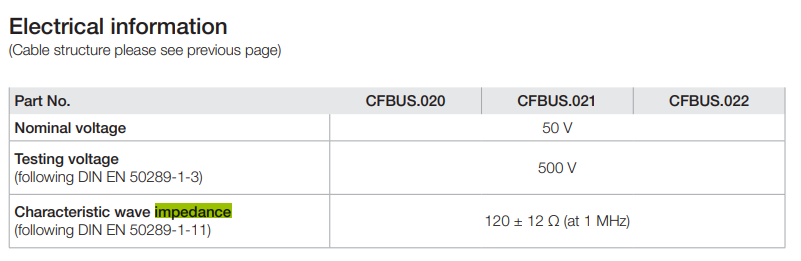

In their daratsheet they are markes as 4x0.25 and not 2x(2x0.25) like other Bus.

-

@fbunel CAN bus only need 2 wires. If you have more than 1 node and you need to run cables along, why not just use 2x CFBUS.021 ? Especially if you don't have to worry about the money.

Bear in mind you need another cable for power though. Usually, the (4x0.25)C cables are used to carry power with the bus for low-power devices (CAN encoders, etc ...) -

@Falcounet

I don't need the 2 can line for now as I have only one tool. But in the near future, I will have more tools so I will need the CAN IN line and the CAN OUT line.Yes, 2x CFBUS.021 is actually a very good idea. I will probably do that.

I just thought this would be way over kill since they are 20AWG and a smaller cable that could flex more would be better.I just realised one thing, since they are so thick, can I also use these cable to run the power line ?

If I run just three of these cable to the toolhead, two for BUS and 1 for power, this will make a pretty neat solution.

Is there a difference between cable like these made for CANBUS and regular power cable ? -

For anyone reading this, I spent 4 hours searching through RS and Farnell for references.

I removed all the cable with impedance not being 120 Ohms, and searched for 22-24 Awg cables.

The one I find that suit the best this application are the following :

(If some of the specialists here could confirm these choice that would be great.)Alpha wire 6413, 2x(2x24AWG), Impedance 120 Ohms, Outer Diameter 7.1mm, Temp -20 to 80, unshielded :

https://fr.farnell.com/alpha-wire/6413-sl005/cable-24awg-2-pair-slate-30-5m/dp/1746265?st=6413Lapp Kabel 2170204T, 2x(2x24AWG), Impedance 100-120 Ohms, Outer Diameter 7.1mm, Temp -5 to 70, shielded (i think)

https://fr.farnell.com/lapp-kabel/2170204t/cable-profibus-par-metre/dp/3034318And if you want way overkill, you can run two of these cable

CFBUS.LB.021, 2x20AWG, Impedance 120 Ohms, Outer Diameter 8.0mm, Temp -50 to 70, shielded

https://fr.rs-online.com/web/p/cables-de-controle/1854913The last one is the only one that is purposely made for dragchains and to move.

I will try my luck with the first one.