Ender 3 mesh grid offset

-

Hey guys, I just want to check if I do everything correctly, can someone double check if my mesh grid coordinates are correct?

; Configuration file for SKR-RFF-E3-v1.1 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.1-LPC-STM32+2 on Tue Dec 28 2021 01:07:55 GMT+0100 (közép-európai téli idő) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Ender3" ; set printer name ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; physical drive 0 goes backwards using TMC2209 driver timings M569 P1 S0 ; physical drive 1 goes backwards using TMC2209 driver timings M569 P2 S1 ; physical drive 2 goes forwards using TMC2209 driver timings M569 P3 S0 ; physical drive 3 goes forwards using TMC2209 driver timings M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E93.00 ; set steps per mm M566 X1200.00 Y1200.00 Z60.00 E360.00 ; set maximum instantaneous speed changes (mm/min) M203 X9000.00 Y9000.00 Z1800.00 E6000.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z100.00 E5000.00 ; set accelerations (mm/s^2) M906 X1000 Y1000 Z1000 E1000 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X235 Y235 Z260 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop ; Z-Probe M950 S0 C"servo0" ; create servo pin 0 for BLTouch M558 P9 C"^probe" H5 F300:120 A3 T6000 ; set Z probe type to bltouch and the dive height + speeds,the F300:120 first speed 300 second 120 G31 P500 X0 Y-47 Z2.15 ; set Z probe trigger value, offset and trigger height M557 X30:190 Y30:190 S10 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bed" T0 ; create bed heater output on bed and map it to sensor 0 M307 H0 B0 R0.365 C296.6 D3.97 S1.00 V24.0 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B4092 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 R2.845 C121.4:119.4 D5.71 S1.00 V24.0 ; disable bang-bang mode for heater and set PWM limit M143 H1 S245 ; set temperature limit for heater 1 to 245C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 C"Part Cooling Fan" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 C"Hotend Fan" S0.01 H1 T45 ; set fan 1 name and value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined M918 P1 E4 E1000000 -

@re_tour theres no need to offset the mesh in X if you probe X offset is 0. You can probe something like X10 to X225

Your Y offset can start at 0 as the probe is in front of the nozzle, but you can't have the last row at 190 as the nozzle would have to be at Y237 for the probe to be at Y190 and Y237 is outside the limits set in M208. Change it to something like Y180 or Y185 -

@jay_s_uk Thank you, I'll give it a go in a moment.

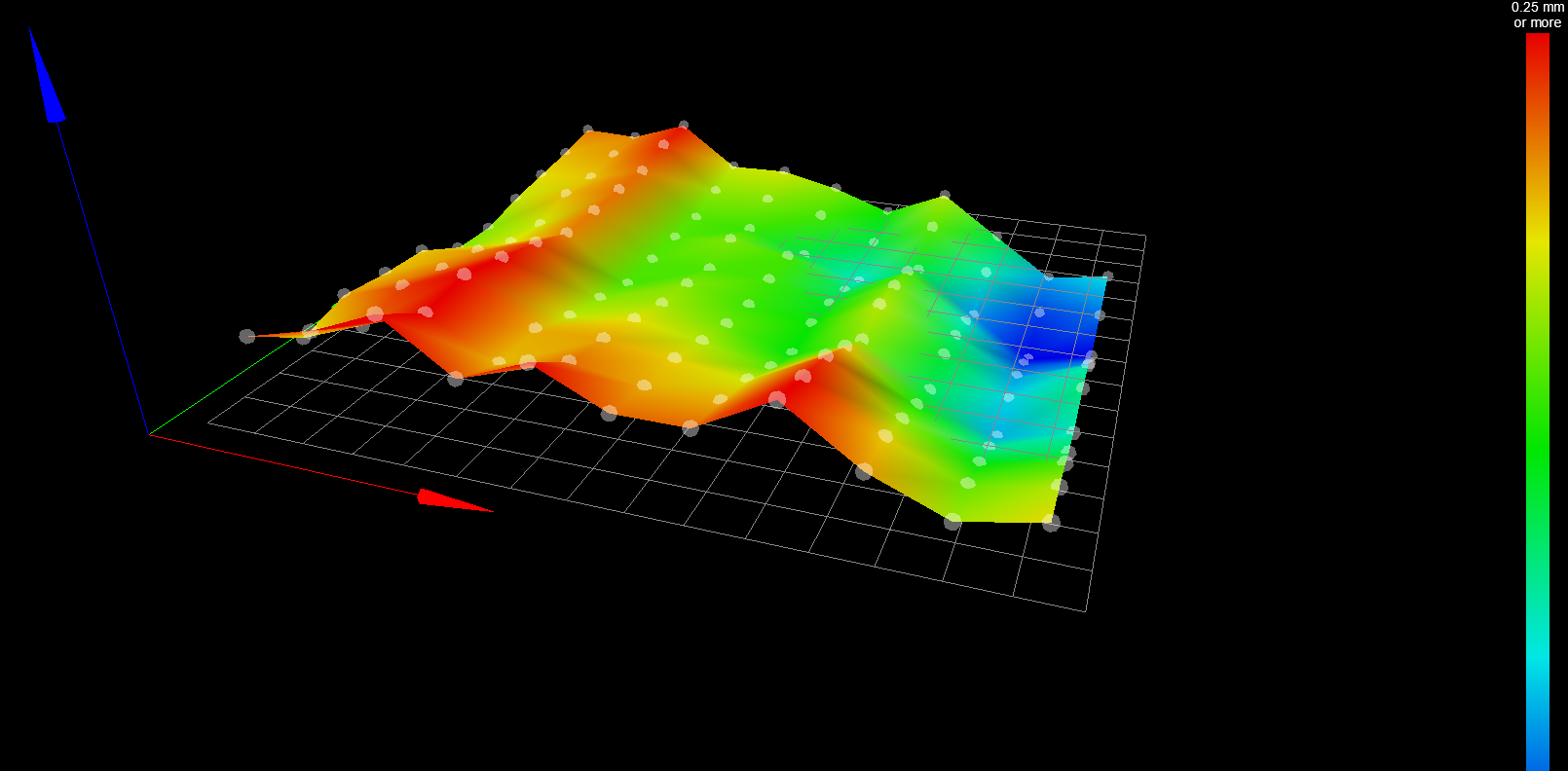

The other thing is that after I do a mesh compensation the grid map is all wobbly which I don't understand and don't know what to do with it. I'll back this up with an image in a few minutes.

-

This is it, what am I doing wrong?

-

@re_tour looks like you may have some movement in your toolhead which may be tilting your probe slightly beween points

-

@jay_s_uk Interesting, how could I test that? I tried moving my tool head but its rock solid, bltouch also has no movement at all, not even bending.

-

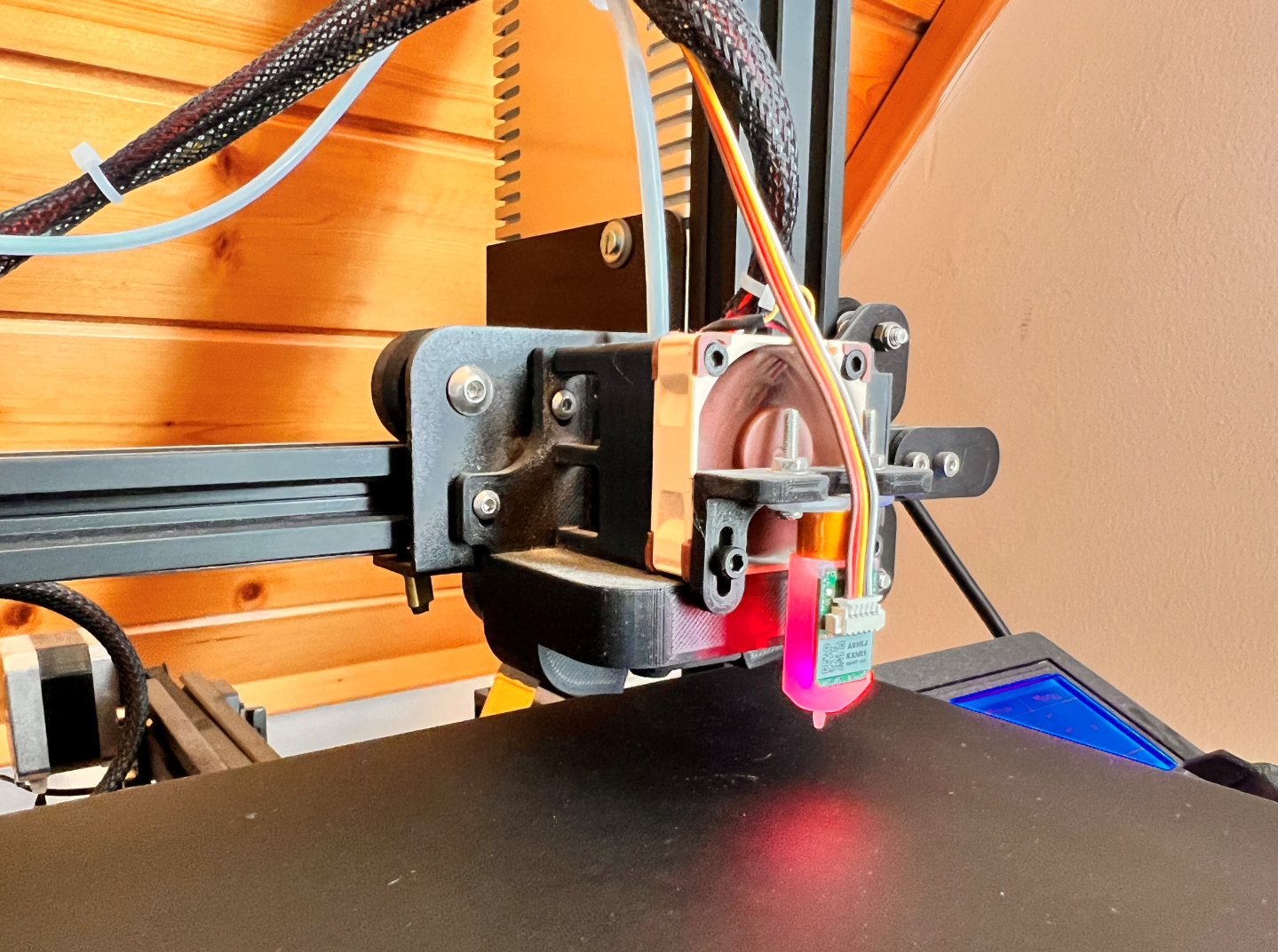

@re_tour thats only a guess though so it may be something else. maybe post a photo of your setup?

-

-

@re_tour do the peaks tie in with the diameter of the rollers?

-

@jay_s_uk Sorry, but what do you mean by that?

-

@re_tour whats the distance between the measuring points in X?

-

@jay_s_uk 15mm

-

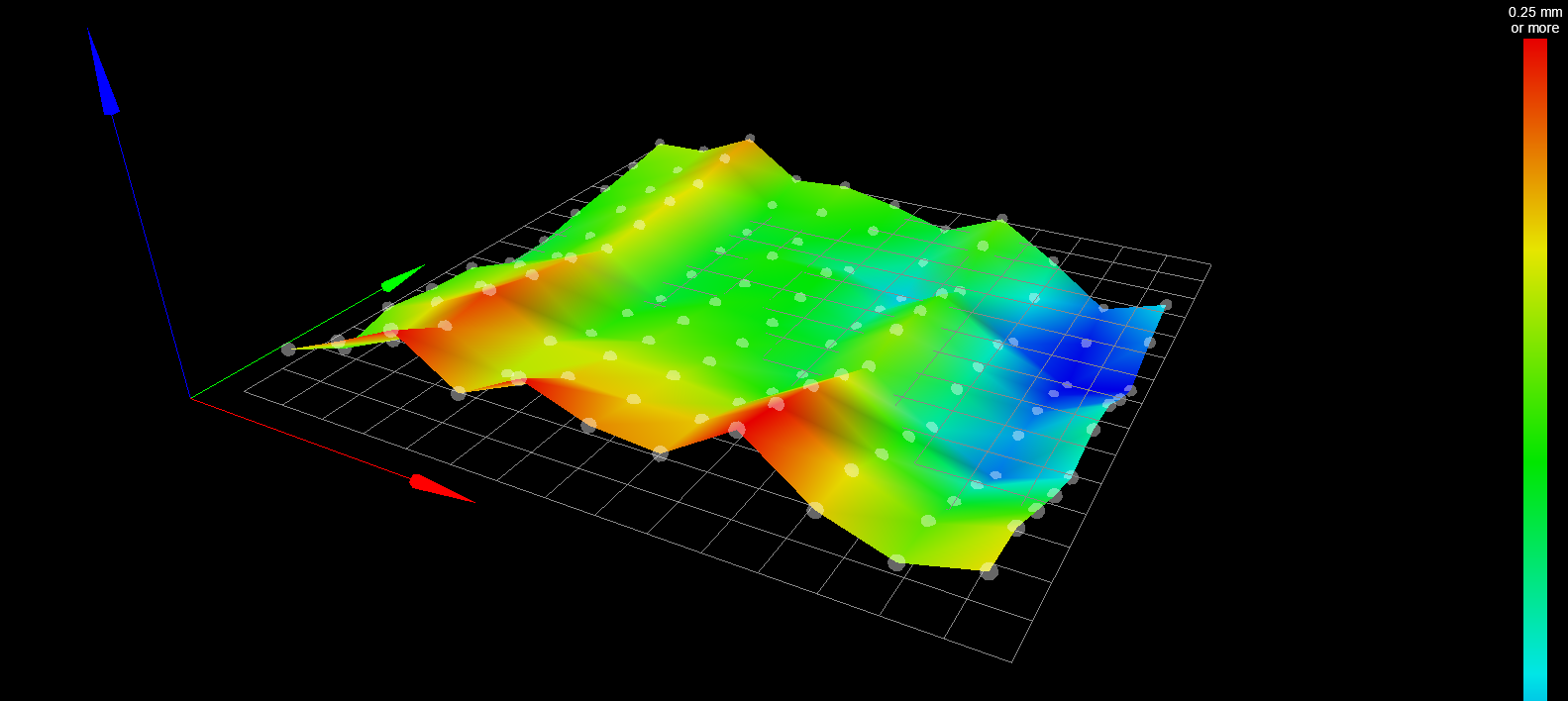

@jay_s_uk I did one more probing and now I have the same pattern with a bit different values

-

@jay_s_uk The rollers are 44,5mm if you think of the ones that move the tool head on X

-

@re_tour the rollers are 24mm. it may be linked to the quality of those. first off i would look at removing them and checking for crunchiness etc in their motion. You may be able to do that with the carriage mounted too.

these are good if you need to replace any https://www.aliexpress.com/item/1005003495562376.html

-

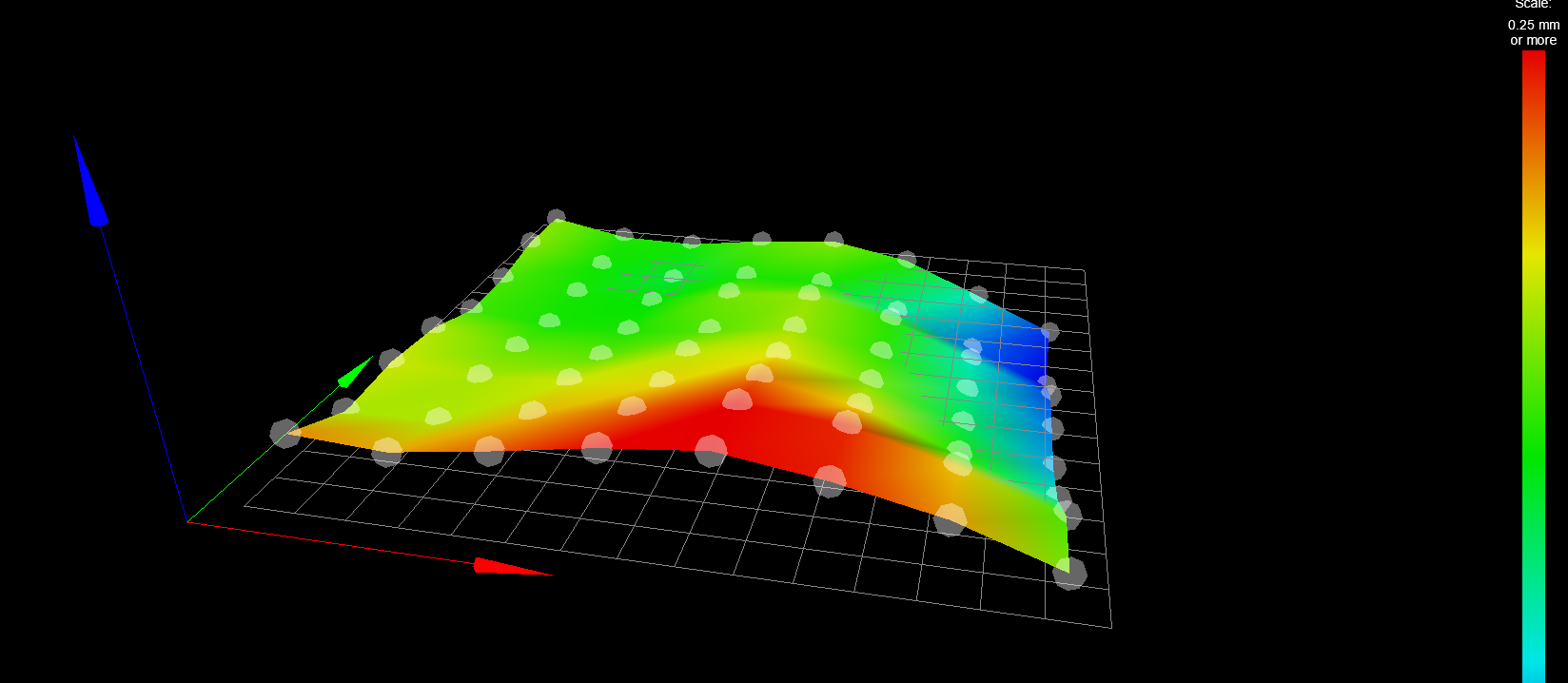

@jay_s_uk well sh#t I guess I never even tought about the fact that debris can build up at the rollers...I did a mesh again, now it looks much better, however, there still is a bump which I dont really know how to correct?

-

@re_tour thats looking better.

It could be a sagging or bent extrusion on X, although sagging seems unlikely -

@jay_s_uk I have a magnetic pad on the bed, but I can't see any depressions or bumps...not visible ones at least, I just cleaned above and below the pads

-

@jay_s_uk Okay so, I cleaned the rollers, the mesh map looks better. I think the bumps should be compensated by the printer. However, now I cant for the love of god make the filament stay on the bed. I have it heated to 65C since the magnetic pad needs a bit higher temperature, but still the filament won't stick. I tried setting the Z offset to a smaller value, the problem is the same. I think the g-code my Cura puts out is also well configured:

; Ender 3 Custom Start G-code G92 E0 ; Reset Extruder G28 ; Home all axes G29 ; Does mesh probing G29 S1 ; Calls the mesh G1 Z2.0 F3000 ; Move Z Axis up little to prevent scratching of Heat Bed G1 X0.1 Y20 Z0.3 F5000.0 ; Move to start position G1 X0.1 Y200.0 Z0.3 F1500.0 E15 ; Draw the first line G1 X0.4 Y200.0 Z0.3 F5000.0 ; Move to side a little G1 X0.4 Y20 Z0.3 F1500.0 E30 ; Draw the second line G92 E0 ; Reset Extruder G1 Z2.0 F3000 ; Move Z Axis up little to prevent scratching of Heat Bed G1 X5 Y20 Z0.3 F5000.0 ; Move over to prevent blob squishThis is the start code. Am I doing something wrong or its a trial end error thing where I have to find the sweet spot?

-

I think the bumps should be compensated by the printer.

It is a common misconception to think of a height map as an image of the print bed’s surface - in fact, it represents the Z-sum of the deviations from the ideal in all mechanical parts. Looking at your latest map, the two bumps (in red and blue) possibly don’t represent deformations of your print bed.

You should be able to verify these "bumps" with a ruler. If these are true deformations, use a mirror tile to flatten the surface. However, I think you should have a second look at your V-slot rollers (all axes). Especially the Y axis of the Ender (and the CR-10) is a common source of "joy" (and quite difficult to fix).

Talking from experience, I know that the Creality printers are well able to lay down a first layer (0.2 mm) without using mesh compensation, just by fixing mechanical issues carefully. If you get that right, put the mesh on top to counter irregularities of the bed’s surface.