Hitachi WJ200 VFD wiring

-

I have a Hitachi WJ200-022-HFE

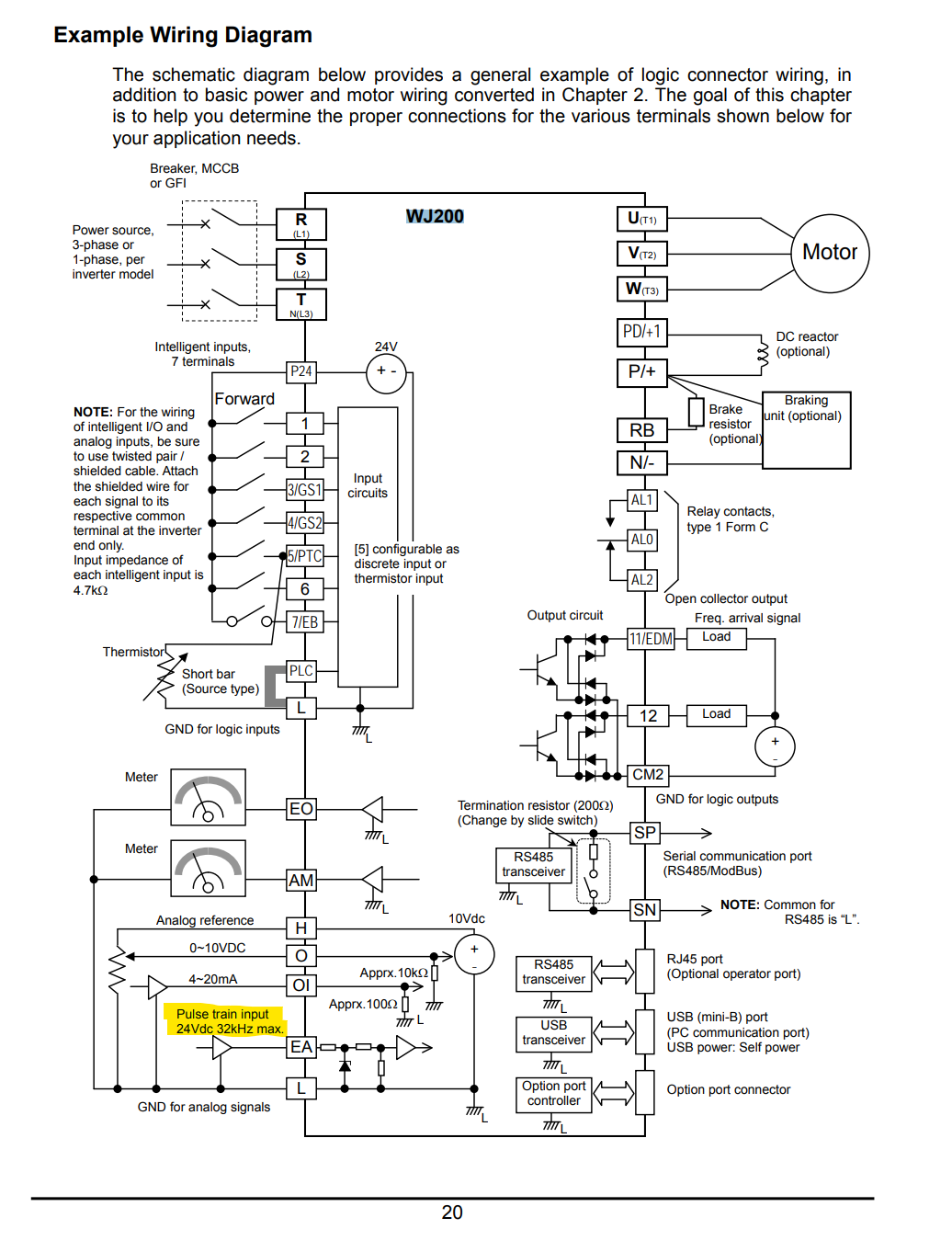

While digging troug the manual I noticed that the VFD has the standard 0-10V analog signal input as well as an 24Vdc "pulse train" input. Do I understand this correctly that I can basically wire a 24V PWM-output from the Duet directly to the EA and L terminals on the VFD in order to controll the spindle motor RPM?

-

I have a Hitachi WJ200-022-HFE

That looks like a very capable VFD! 3-phase, 400V, 2.2kW... yikes! Not sure what the 'E' in HFE stands for?

I had a look at the English versions of the manual (sorry, my German isn't good enough for reading the pdf you linked!) https://www.hitachi-iesa.com/sites/default/files/supportdocs/(WJ200)SM-E265W.pdf or https://www.hitachi-iesa.com/sites/default/files/supportdocs/NT3251X.pdf (I think your image comes from this one), but the huge number of configurable options are equally baffling to me.

However, I don't think you can control it using 24V PWM from a Duet, because the Duet doesn't output 24V PWM, eg on the heater and fan outputs. It outputs 24V constantly, and the PWM switching is on the ground side (because MOSFETs work best if they are placed after the load). But there seems to be so many 'Pulse train' options in the documentation, I could easily be wrong.

I think the easiest option is to use a board to convert PWM to the 0-10V range, and use that input. See https://docs.duet3d.com/en/User_manual/Machine_configuration/Configuration_CNC#connecting-a-spindle

Ian

-

@MaxGyver

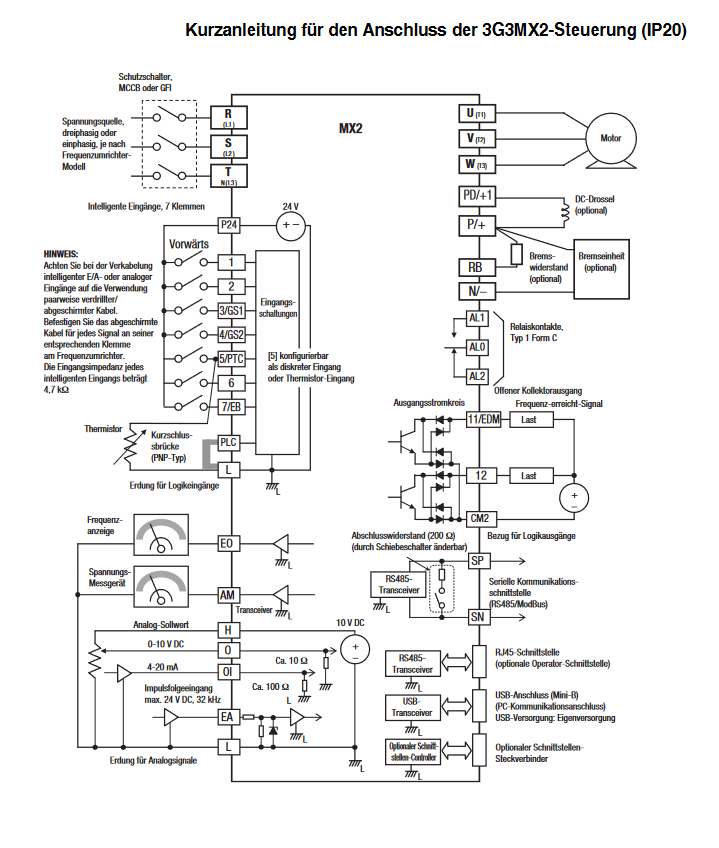

That looks like the Omron MX2The impulse train input for the omron is for a rotary encoder feedback (position control).

I use a custom PWM -> 0-10V converter to drive the inverter from duet.

-

Thank you all for your feedback.

I went with the PWM to 0-10V Analog converter to control the spindle. I would have preferred a direct interface between Duet and VFD. It would simplify the wiring, eliminate the extra space requirements for the PCB and for me it just feels kind of wrong to have a 5€ China PCB controlling the most expensive components on my CNC. If I recall correctly a 0-10V analog output for interfacing VFD's is already on the Duet3 Hardware wishlist?

-

@MaxGyver it might be. But that requires extra circuitry, and additional cost. Also, it’s been reported by @jay_s_uk that the spindle speed can vary if the voltage wanders, I guess depending on the quality of the PWM to 0-10V conversion and maybe interference or wiring losses. RS485 and Modbus has been suggested as a better way to control spindles, and is under consideration.

Ian