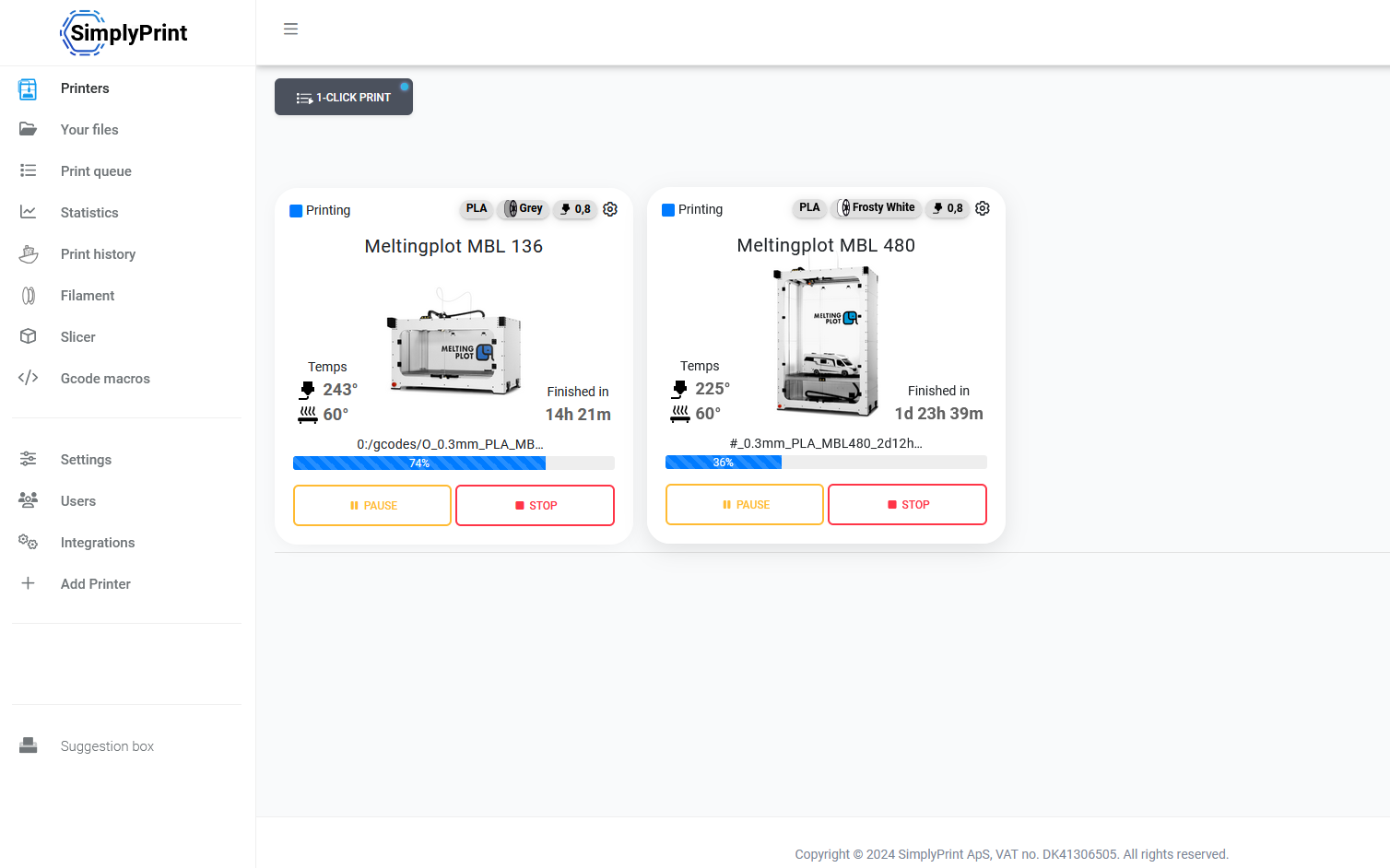

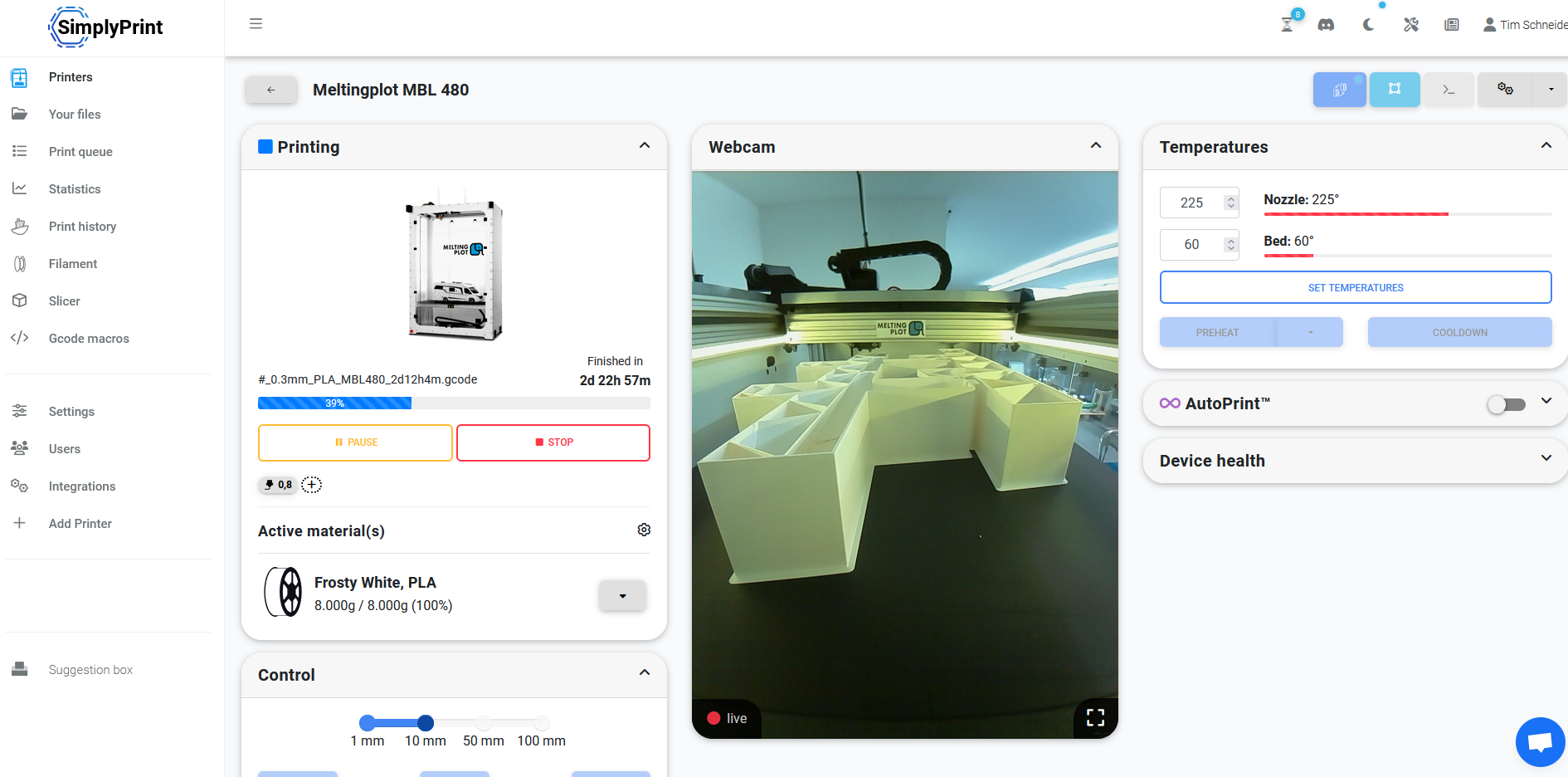

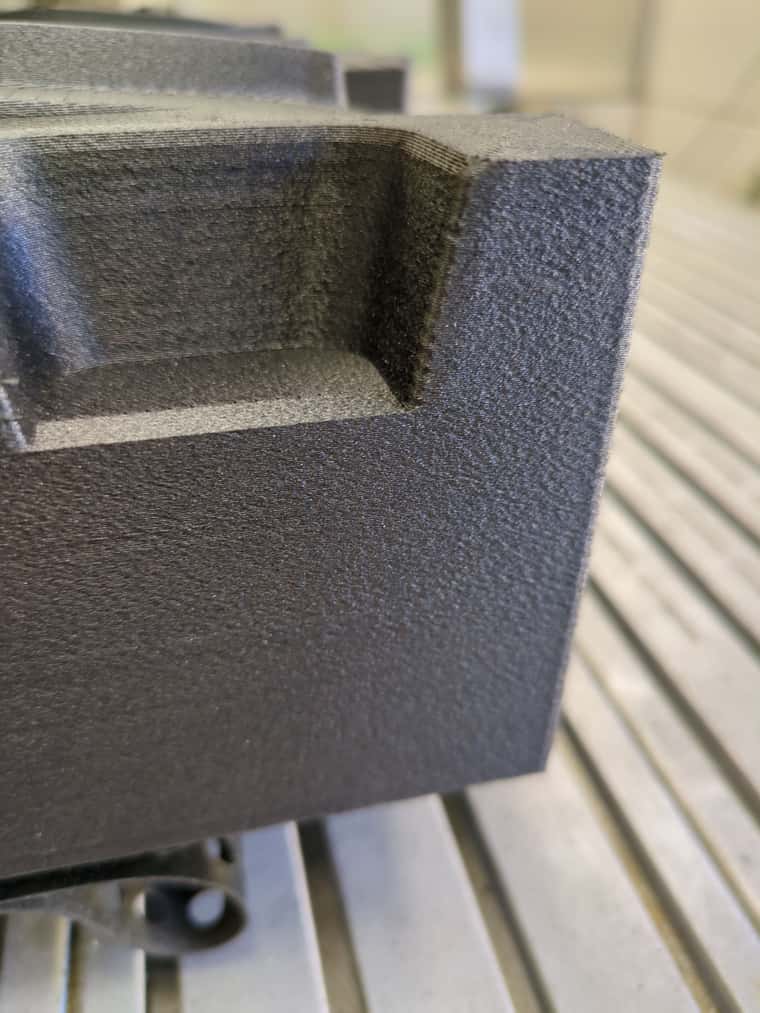

Another failure today

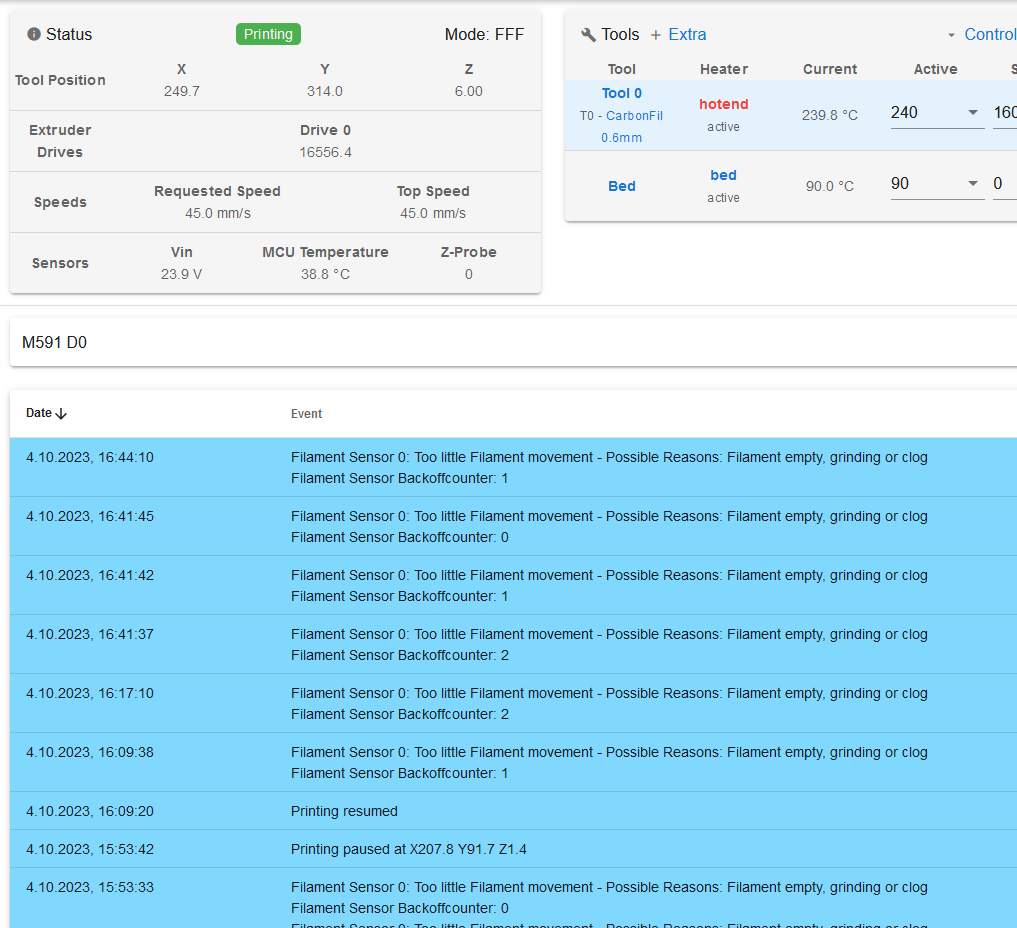

Feb 15 22:05:47 Meltingplot-MBL-480-vaswsq DuetControlServer[4948]: [info] Printing resumed

Feb 16 00:59:08 Meltingplot-MBL-480-vaswsq DuetControlServer[4948]: [warn] Restarting full transfer because a bad header format code was received (0xff)

Feb 16 00:59:09 Meltingplot-MBL-480-vaswsq DuetControlServer[4948]: [warn] Lost connection to Duet (Timeout while waiting for transfer ready pin)

Feb 16 00:59:09 Meltingplot-MBL-480-vaswsq DuetControlServer[4948]: [info] Connection to Duet established

Feb 16 00:59:09 Meltingplot-MBL-480-vaswsq DuetControlServer[4948]: [warn] Daemon: Aborting orphaned macro file daemon.g

Feb 16 00:59:09 Meltingplot-MBL-480-vaswsq DuetControlServer[4948]: [info] Aborted macro file daemon.g

Feb 16 00:59:09 Meltingplot-MBL-480-vaswsq DuetControlServer[4948]: [warn] SPI connection has been reset

Feb 16 00:59:09 Meltingplot-MBL-480-vaswsq DuetControlServer[4948]: [info] Aborted job file

Feb 16 00:59:09 Meltingplot-MBL-480-vaswsq DuetControlServer[4948]: [info] Starting macro file config.g on channel Trigger

Feb 16 00:59:15 Meltingplot-MBL-480-vaswsq DuetControlServer[4948]: [error] M584: Driver 50.0 does not exist

Feb 16 00:59:15 Meltingplot-MBL-480-vaswsq DuetControlServer[4948]: Driver 51.0 does not exist

Feb 16 00:59:15 Meltingplot-MBL-480-vaswsq DuetControlServer[4948]: [info] Starting macro file config-override.g on channel Trigger

Feb 16 00:59:15 Meltingplot-MBL-480-vaswsq DuetControlServer[4948]: [info] Trigger: Finished macro file config-override.g

Feb 16 00:59:15 Meltingplot-MBL-480-vaswsq DuetControlServer[4948]: [info] Event logging stopped

Feb 16 00:59:15 Meltingplot-MBL-480-vaswsq DuetControlServer[4948]: [info] Event logging to 0:/sys/eventlog.log started

2025-02-15 22:05:47 Printing resumed

2025-02-16 00:59:09 Warning: Lost connection to Duet (Timeout while waiting for transfer ready pin)

2025-02-16 00:59:09 Connection to Duet established

2025-02-16 00:59:09 Warning: SPI connection has been reset

2025-02-16 00:59:09 Connection to SBC established!

2025-02-16 00:59:15 Error: M584: Driver 50.0 does not exist

Driver 51.0 does not exist

2025-02-16 00:59:15 G10 P0 X0 Y0 Z0

2025-02-16 00:59:15 G10 P0 R0 S0

2025-02-16 00:59:15 G10 L2 P1 X0.000000 Y0.000000 Z0.000000

2025-02-16 00:59:15 G10 L2 P2 X0.000000 Y0.000000 Z0.000000

2025-02-16 00:59:15 G10 L2 P3 X0.000000 Y0.000000 Z0.000000

2025-02-16 00:59:15 G10 L2 P4 X0.000000 Y0.000000 Z0.000000

2025-02-16 00:59:15 G10 L2 P5 X0.000000 Y0.000000 Z0.000000

2025-02-16 00:59:15 G10 L2 P6 X0.000000 Y0.000000 Z0.000000

2025-02-16 00:59:15 G10 L2 P7 X0.000000 Y0.000000 Z0.000000

2025-02-16 00:59:15 G10 L2 P8 X0.000000 Y0.000000 Z0.000000

2025-02-16 00:59:15 G10 L2 P9 X0.000000 Y0.000000 Z0.000000

2025-02-16 00:59:15 Event logging stopped

2025-02-16 00:59:15 Event logging started

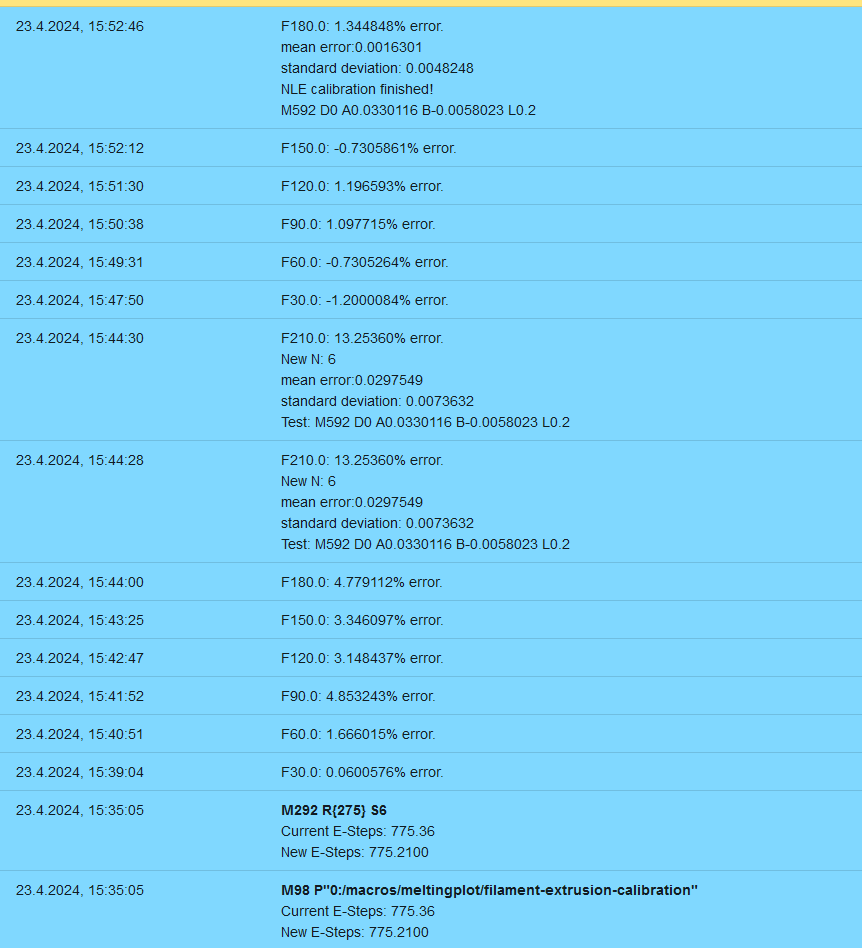

M122

=== Diagnostics ===

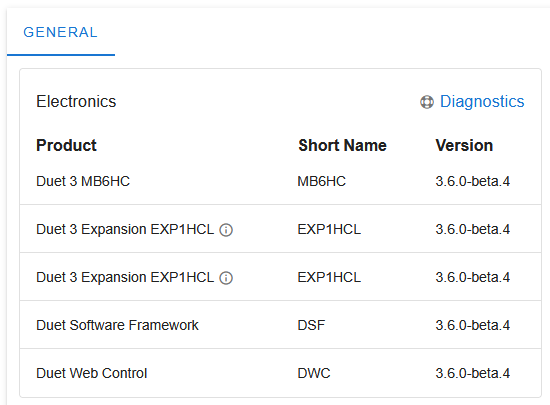

RepRapFirmware for Duet 3 MB6HC version 3.6.0-beta.4 (2025-02-11 09:51:22) running on Duet 3 MB6HC v1.02 or 1.02a (SBC mode)

Board ID: 08DJM-9P63L-DJ3T8-6JKD4-3SJ6K-9A77A

Used output buffers: 1 of 40 (17 max)

Error in macro line 29 while starting up: M584: Driver 50.0 does not exist

Driver 51.0 does not exist

=== RTOS ===

Static ram: 137396

Dynamic ram: 98044 of which 3056 recycled

Never used RAM 105560, free system stack 180 words

Tasks: LASER(5,nWait 7,0.0%,269) SBC(2,nWait 7,1.0%,725) HEAT(3,nWait 6,0.0%,323) Move(4,nWait 6,0.0%,323) TMC(4,nWait 6,3.0%,375) CanReceiv(6,nWait 1,0.0%,805) CanSender(5,nWait 7,0.0%,334) CanClock(7,delaying,0.0%,350) MAIN(1,running,95.9%,101) IDLE(0,ready,0.0%,29) USBD(3,blocked,0.0%,144), total 100.0%

Owned mutexes: HTTP(MAIN)

=== Platform ===

Last reset 06:21:05 ago, cause: software

Last software reset at 2025-02-16 00:59, reason: WatchdogTimeout, Gcodes spinning, available RAM 83312, slot 1

Software reset code 0x00a3 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x1440e04f BFAR 0x00000000 SP 0x2045ffa8 Task MAIN Freestk 78286 ok

Stack: fff530e0 0000f850 0000f850 0000f850 f846069c 00000000 0044b234 a1030027 ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff

=== Storage ===

Free file entries: 20

SD card 0 not detected, interface speed: 37.5MBytes/sec

SD card longest read time 0.0ms, write time 0.0ms, max retries 0

=== Move ===

Segments created 0, maxWait 0ms, bed comp in use: none, height map offset 0.000, hiccups added 0/0 (0.00/0.00ms), max steps late 0, ebfmin 0.00, ebfmax 0.00

Pos req/act/dcf: 0.00/0/0.00 0.00/0/0.00 0.00/0/0.00

Next step interrupt due in 140 ticks, disabled

Driver 0: standstill, SG min n/a, mspos 8, reads 53019, writes 11 timeouts 0

Driver 1: standstill, SG min n/a, mspos 8, reads 53019, writes 11 timeouts 0

Driver 2: standstill, SG min n/a, mspos 760, reads 53006, writes 24 timeouts 0

Driver 3: standstill, SG min n/a, mspos 40, reads 53006, writes 24 timeouts 0

Driver 4: standstill, SG min n/a, mspos 232, reads 53006, writes 24 timeouts 0

Driver 5: standstill, SG min n/a, mspos 260, reads 53008, writes 22 timeouts 0

Phase step loop runtime (us): min=0, max=18, frequency (Hz): min=1918, max=2094

=== DDARing 0 ===

Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0]

Segments left 0, axes/extruders owned 0x00000000, drives owned 0x00000000

Code queue is empty

=== DDARing 1 ===

Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0]

Segments left 0, axes/extruders owned 0x00000000, drives owned 0x00000000

Code queue is empty

=== Heat ===

Bed heaters 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1 -1 -1 -1 -1, ordering errs 0

=== GCodes ===

Movement locks held by null, null

HTTP* is doing "M122" in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger* is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon* is idle in state(s) 0 0, running macro

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

File2 is idle in state(s) 0

Queue2 is idle in state(s) 0

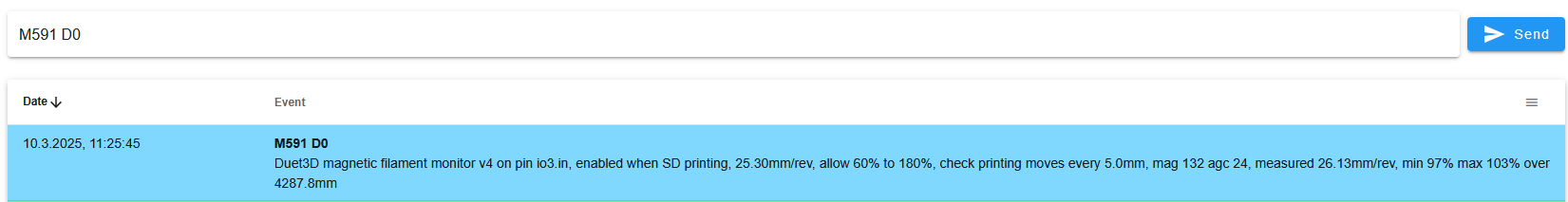

=== Filament sensors ===

Driver 31: pos 13718.32, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0

=== CAN ===

Messages queued 199813, received 365858, lost 0, ignored 0, errs 0, boc 0

Longest wait 241ms for reply type 6041, peak Tx sync delay 384, free buffers 50 (min 49), ts 108370/108369/0

Tx timeouts 0,0,0,0,0,0

=== SBC interface ===

Transfer state: 5, failed transfers: 0, checksum errors: 0

RX/TX seq numbers: 53927/29369

SPI underruns 0, overruns 0

State: 5, disconnects: 0, timeouts: 0 total, 0 by SBC, IAP RAM available 0x27a80

Buffer RX/TX: 0/0-0, open files: 0

=== Duet Control Server ===

Duet Control Server version 3.6.0-beta.4 (2025-02-11 12:02:27, 32-bit)

HTTP+Executed:

> Executing M122

Daemon:

>> Doing macro daemon.g, started by system

Code buffer space: 4096

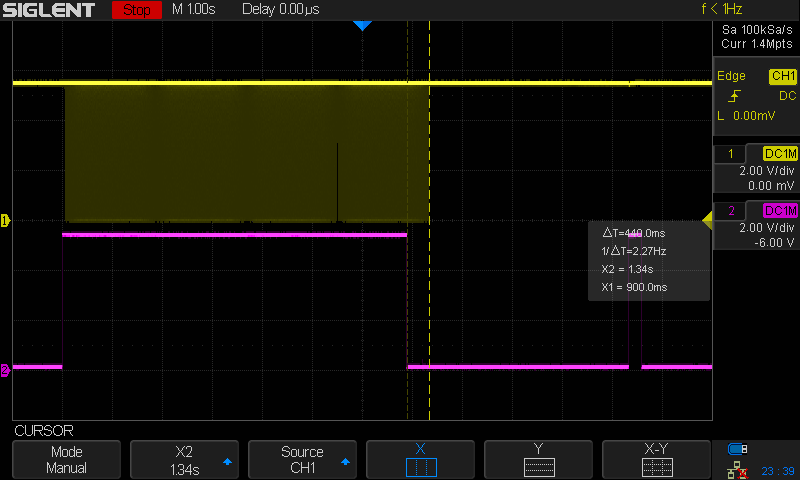

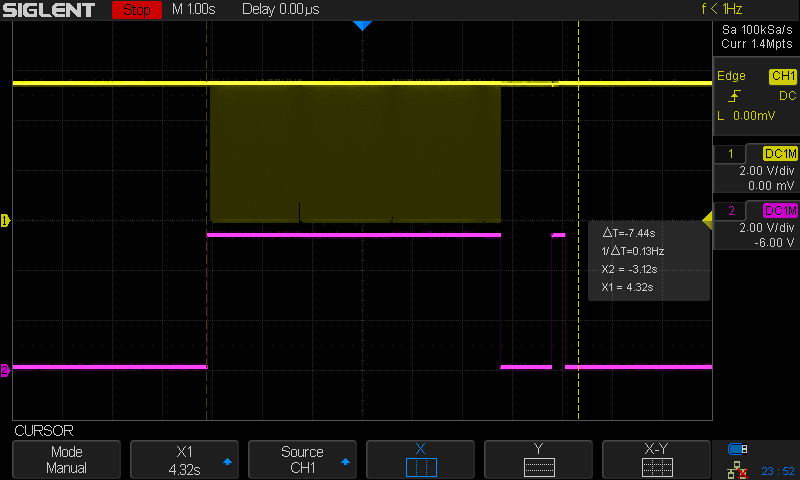

Configured SPI speed: 8000000Hz, TfrRdy pin glitches: 1

Full transfers per second: 39.57, max time between full transfers: 85.1ms, max pin wait times: 945.5ms/6.2ms

Codes per second: 8.62

Maximum length of RX/TX data transfers: 5444/1664

M122 B50

Diagnostics for board 50:

Duet EXP1HCL rev 1.0a or earlier firmware version 3.6.0-beta.4 (2025-02-10 20:09:59)

Bootloader ID: SAME5x bootloader version 2.4 (2021-12-10)

All averaging filters OK

Never used RAM 45228, free system stack 178 words

Tasks: EncCal(1,nWait 6,0.0%,469) Move(3,nWait 7,0.1%,97) CLSend(3,nWait 6,0.0%,149) TMC(4,nWait 6,70.4%,317) HEAT(2,nWait 6,0.1%,105) CanAsync(5,nWait 4,0.0%,70) CanRecv(3,nWait 1,0.0%,31) CanClock(5,nWait 1,0.0%,63) MAIN(1,running,28.1%,253) IDLE(0,ready,0.0%,29) AIN(2,nWait 2,1.3%,255), total 100.0%

Owned mutexes:

Last reset 20:42:45 ago, cause: software

Last software reset data not available

Moves scheduled 410248, hiccups 0 (0.00/0.00ms), segs 259, step errors 0 (types 0x0), maxLate 0 maxPrep 2467, ebfmin 0.00 max 0.00

Phase step loop runtime (us): min=34, max=69, frequency (Hz): min=488, max=17045

Peak sync jitter -10/6, peak Rx sync delay 192, resyncs 0/1, next timer interrupt due in 4 ticks, enabled, next step interrupt due in 4205270383 ticks, disabled

VIN voltage: min 24.6, current 24.6, max 24.6

V12 voltage: min 12.2, current 12.2, max 12.2

MCU temperature: min 29.2C, currentDriver 0: pos 1924, 80.0 steps/mm, ok, SG min n/a, mspos 8, reads 55386, writes 16871 timeouts 1524

Last sensors broadcast 0x00000000 found 0 63 ticks ago, 0 ordering errs, loop time 0

CAN messages queued 596576, send timeouts 0, received 1061897, lost 0, ignored 0, errs 0, boc 0, free buffers 38, min 33, error reg 0

dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 573, adv 17915/70063

Closed loop driver 0 mode: closed loop, pre-error threshold: 2.00, error threshold: 4.00, encoder type rotaryAS5047, position 9853

Encoder reverse polarity: yes, full rotations 0, last angle 9854, minCorrection=-9.0, maxCorrection=9.4, agc 57, mag 4645, no error

Tuning mode: 0, tuning error: 0, collecting data: no

Accelerometer: none

I2C bus errors 12, naks 0, contentions 0, other errors 0

M122 B51

Diagnostics for board 51:

Duet EXP1HCL rev 1.0a or earlier firmware version 3.6.0-beta.4 (2025-02-10 20:09:59)

Bootloader ID: SAME5x bootloader version 2.4 (2021-12-10)

All averaging filters OK

Never used RAM 44892, free system stack 174 words

Tasks: EncCal(1,nWait 6,0.0%,469) Move(3,nWait 7,0.1%,97) CLSend(3,nWait 6,0.0%,149) TMC(4,nWait 6,70.2%,317) HEAT(2,nWait 6,0.1%,105) CanAsync(5,nWait 4,0.0%,70) CanRecv(3,nWait 1,0.0%,31) CanClock(5,nWait 1,0.0%,63) MAIN(1,running,28.3%,253) IDLE(0,ready,0.0%,29) AIN(2,nWait 2,1.3%,255), total 100.0%

Owned mutexes:

Last reset 20:43:05 ago, cause: software

Last software reset data not available

Moves scheduled 371581, hiccups 0 (0.00/0.00ms), segs 273, step errors 0 (types 0x0), maxLate 0 maxPrep 2394, ebfmin 0.00 max 0.00

Phase step loop runtime (us): min=34, max=70, frequency (Hz): min=491, max=16304

Peak sync jitter -7/9, peak Rx sync delay 192, resyncs 0/1, next timer interrupt due in 1 ticks, enabled, next step interrupt due in 4190702455 ticks, disabled

VIN voltage: min 24.2, current 24.2, max 24.3

V12 voltage: min 12.0, current 12.1, max 12.1

MCU temperature: min 28.2C, current Driver 0: pos -1824, 80.0 steps/mm, ok, SG min n/a, mspos 8, reads 21706, writes 13725 timeouts 1238

Last sensors broadcast 0x00000000 found 0 131 ticks ago, 0 ordering errs, loop time 0

CAN messages queued 596733, send timeouts 0, received 1023400, lost 0, ignored 0, errs 0, boc 0, free buffers 38, min 32, error reg 0

dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 544, adv 18140/70373

Closed loop driver 0 mode: closed loop, pre-error threshold: 2.00, error threshold: 4.00, encoder type rotaryAS5047, position 9340

Encoder reverse polarity: yes, full rotations 0, last angle 9341, minCorrection=-35.3, maxCorrection=30.5, agc 47, mag 4612, no error

Tuning mode: 0, tuning error: 0, collecting data: no

Accelerometer: none

I2C bus errors 12, naks 0, contentions 0, other errors 0

not rock solid, as I can still crash it - but mostly solid

not rock solid, as I can still crash it - but mostly solid