Need help to calculate rail size for new printer

-

Hello! im looking to build a new delta printer (DuetWiFi of course)

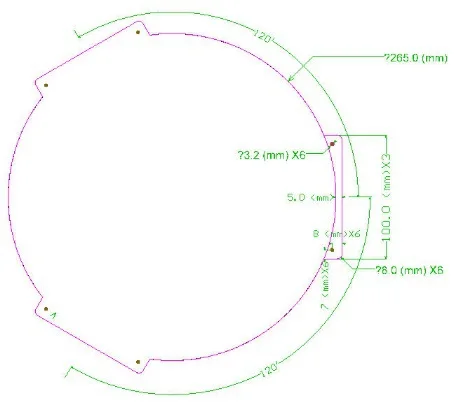

and pre-selected headbed (below)

i think to use 2040 rail for more stability…Questions:

- do you think 2040 rail will be significantly stable compared to 2020 rail ?

- how to calculate needed length of rail for top / bottom ?

thank you in advance!

-

There is no easy formula, because the length of the rails depends on the geometry of the frame vertices you use. I found out that the Robotdigg aluminium vertices for 2020 and 2040 extrusions need different rail lengths when I converted my printer from 2020 to 2040 extrusions.

-

Daid,

I converted my printer from 2020 to 2040 extrusions.

do you find your printer much more stable on 2040? or it does not worth such an upgrade ???

-

My printer is 1m tall with a print diameter of 300mm. I didn't notice any stability issues with the previous 2020 extrusions, but I never printed a tall object on it. When building a printer of that size from scratch, the additional cost of using 2040 instead of 2020 is relatively small, so worthwhile IMO. But whether it was worthwhile for me to buy new extrusions and vertices and sell the old ones at a bargain price is much less clear. It's much the same with 0.9deg vs 1.8deg motors - it's worth buying 0.9deg motors in the first place because the additional cost is small, but probably not worth upgrading an existing printer from 1.8deg to 0.9deg.

-

David, what is your opinion on wide (300mm), but not tall printer (600-700mm)?

2020 or 2040 ? -

David, what is your opinion on wide (300mm), but not tall printer (600-700mm)?

2020 or 2040 ?My guess is that 2020 would be adequate. But how much extra does 2040 cost compared to 2020? There might be an observable difference if you print tall objects at high print speeds and accelerations.

-

2040 ads less than 25% to 2020 profile

and almost 100% on alloy corners.I'm building high precision machine that i want to run high speed… and it should look proportional :))

another thing that i want to do - is to hide power supply and DuetWiFi board under the plate.

with either type of profile i will need to get "3rd row" of corners.

1st will be sitting on the desk,

2nd - will hold the plate

3rd one - on the top.electronics will be between 1st and 2nd. for thermal isolation i found great material - aerogel https://youtu.be/5sw1tNeJ0Rw fantastic material! that will be on the build plate back

-

Check out my build at https://miscsolutions.wordpress.com/dc42s-large-kossel-build/, you can hide the PSU and Duet under the bed using standard 60mm high 2020 or 2040 vertices.

-

If you intend to use Robotdigg 2040 style corners, try this calculator:

Tip: Drag the effector to move it. Drag NOT on the effector to orbit/pan the whole printer. Try all your mouse buttons and rollers.

-

Nice work but what with the banana lol

-

I guess it is used to match printer with real size… assuming you have seen banana at least once :))

-

I'd got for 2040 for an Xl sized machine I did and the frame is very stiff. 2020 with cross bracing works but I its not a clean or neat look IMO.

Also if buying linear rail for axes a 1m tall printer only needs 600mm rail unless your rods are too short I bought longer and had to cut them down,and they cost more.

My build is here http://forums.reprap.org/read.php?178,702599 was based on David's but included everything up to date as of about a year ago. Now sporting smarteffector, nimble and enclosure/watercooling.

-

Nice work but what with the banana lol

Obscure reference to reddit.

And, when you zoom in, it really does have a scale…