PT1000 thermistor configuration

-

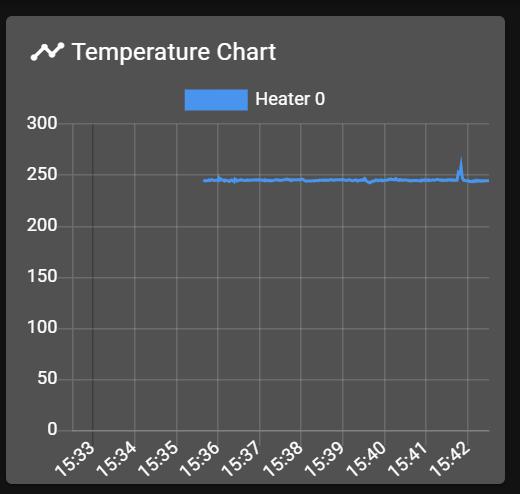

@droftarts I did not notice if temp spikes then heaters are off. But this is a little spike I was able to capture while heater is on:

-

@Arminas Please note that PT1000 (and PT100) temperature sensors are NOT thermistors. They are a Platinum (PT) Resistance Temperature Detector (RTD), with a resistance of 1000ohms (or 100ohms for PT100) at 0°C. Their resistance increases as the temperature increases, and are also all made to match the standard resistance vs temperature table. This is why you don't need any additional parameters in the M308 command when configuring PT1000.

The resistance of a thermistor decreases as temperature increases, and thermistors come in a wide range of values, and have a wide range of responses to temperature increases.

Ian

-

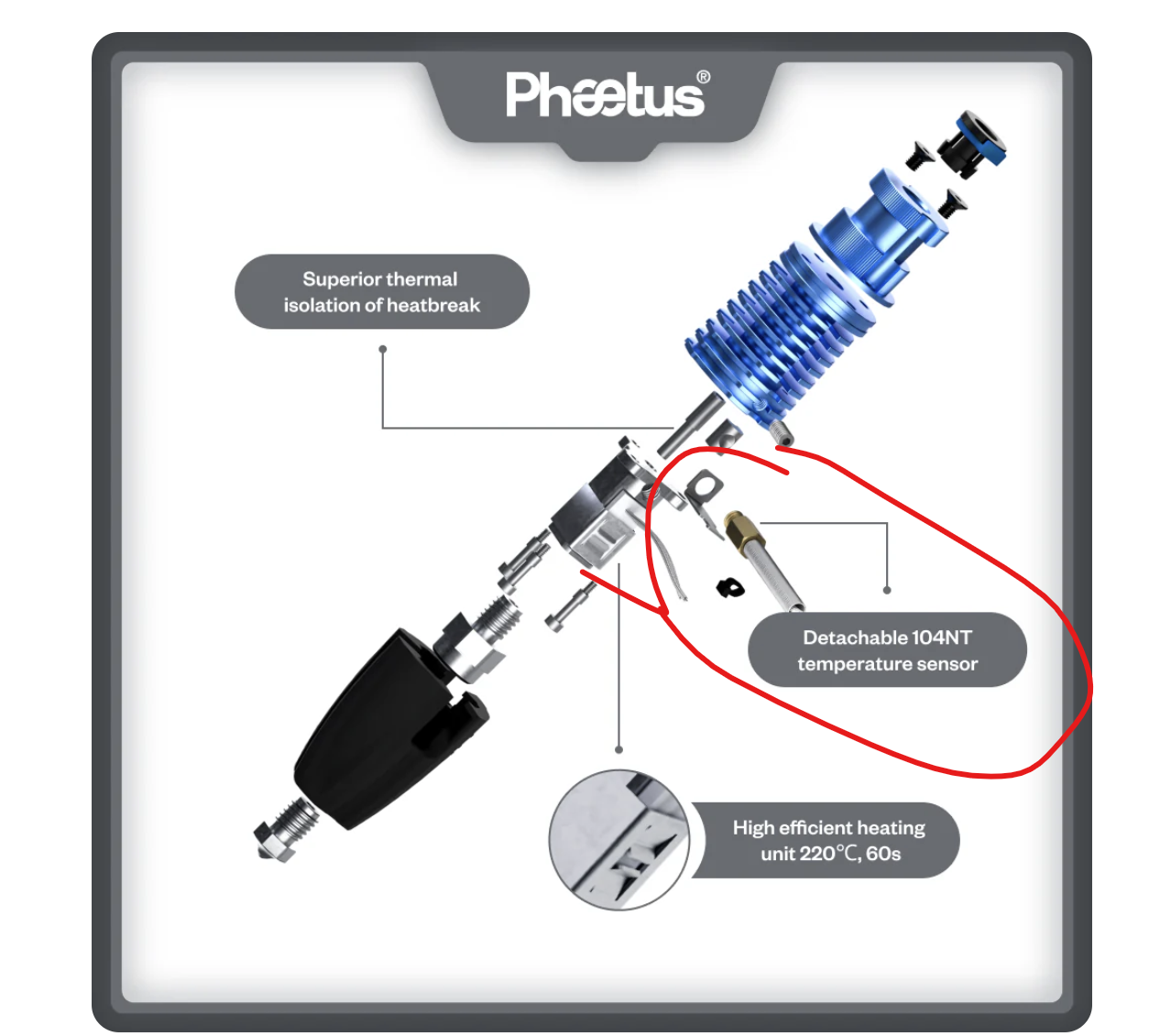

@droftarts my bad, I am talking about PT1000 temp sensor. I am a bit lost with phaetus rapido hotends, I don't understand what I have. I want to buy a replacement temp sensor, but it does not look the same as what I have right now.

-

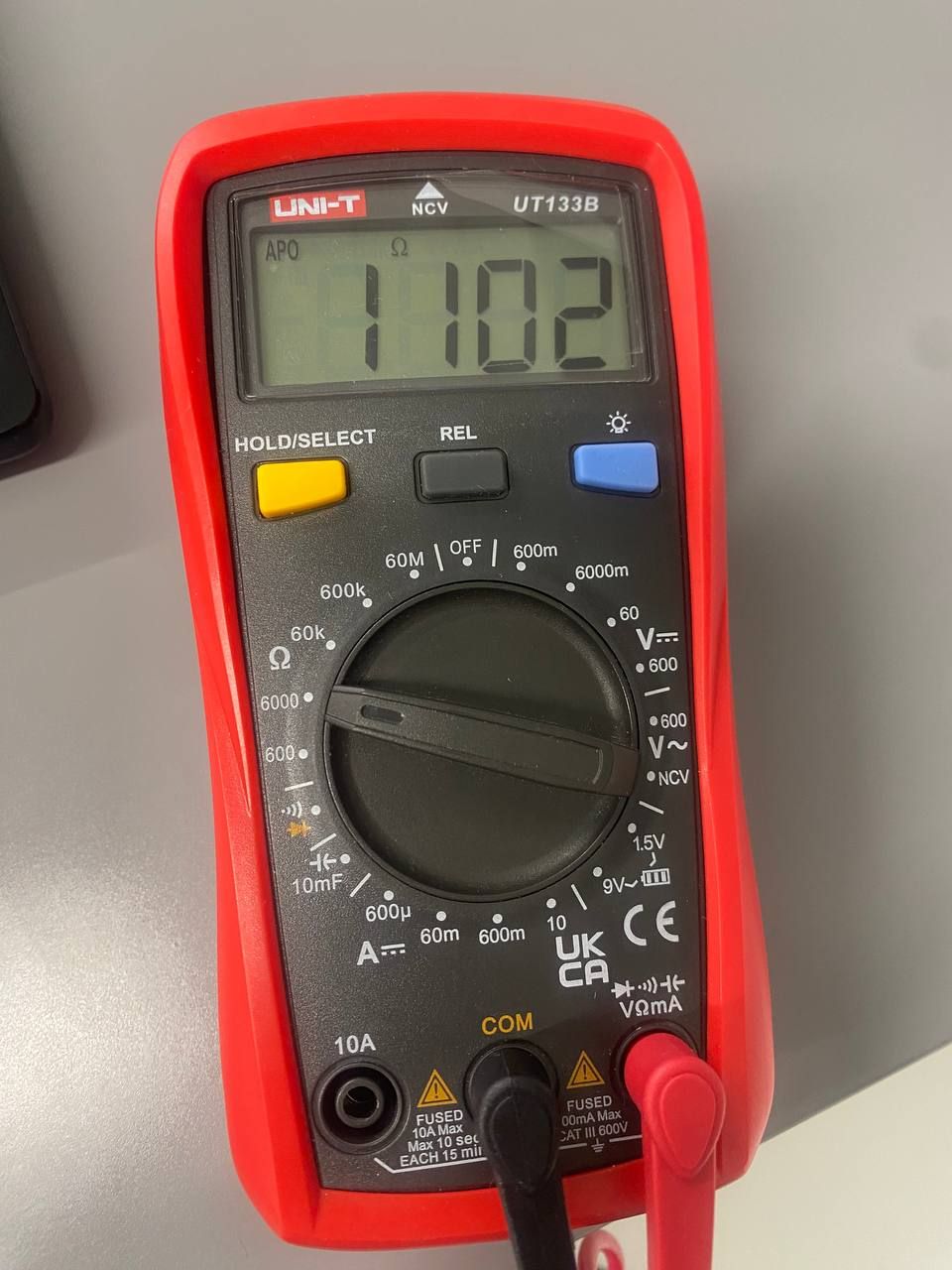

@Arminas If you have a multimeter, check the resistance at room temperature. A PT1000 should be 1077 ohms at 20C (see https://www.sterlingsensors.co.uk/pt1000-resistance-table). A 100K NTC thermistor will be around 123300 ohms at 20C (100000 ohms at 25C) see https://api.mikroelectron.com/storage/862/186d503e-bf2a-4279-ac77-9b94ce1f0c80.png.

Ian

-

@droftarts okay, it's above 20C in my room and I have 1102 ohms, so it's PT1000.

Any ideas where can I buy PT1000 rapido temp sensor? everyone sells this one https://3do.dk/en/spare-parts/1250-rapido20-heateblock-3.html but mine does not have thread, it looks different

-

in Phaetus website this one is marked as 104NT

I don't understand what is what -

@Arminas I think your hot end looks like a Rapido 2F or 2 plus, which talks about having a PT1000: https://www.phaetus.com/products/rapido-2f

The picture you posted looks like the Rapido 2.Ian

-

@droftarts mine should be 2 plus. Is it normal if multimeter shows 774 ohms (less then measuring unplugged temp sensor) if I measure the temp sensor pins on toolboard?

-

@Arminas The temperature circuit is a voltage divider with inline resistors, so yes, you should read some resistance. It looks like you're measuring across the temp sensor pins with the PT1000 still connected. In which case you're measuring about 1100 ohms in parallel with about 2K to 3K. So 774 ohms is believable. I just measured a bare 1LC board, and get 2.7k ohms on temp0 and temp1. See the schematic here: https://github.com/Duet3D/Duet3-Toolboard-1LC/blob/master/Toolboard_1LC_v1.3/Duet3_TB_1LC_Schematic_v1.3.pdf

Ian

-

@droftarts Could you please explain a little more about this test - how do I differ if it's board or wiring? Maybe I can measure resistance of temp sensor pins on the board?

-

@Arminas said in PT1000 thermistor configuration:

Could you please explain a little more about this test

- Turn off power, disconnect the PT1000 from the 1LC

- Measure the resistance on the wires to the PT1000. You have already done this, resistance was 1102 ohms.

- Measure the resistance across the temp0 pins of the 1LC, without the PT1000 connected. It should be around 2.7k ohms. Measure the temp1 pins as well.

Generally, in order of most likely to least likely, spiky temperature readings are caused by:

- intermittent wiring - loose connections, poor crimping, frayed wires, dry solder joints. It may only happen when the wiring moves, or when temperature changes.

- failing temperature sensor - may only show when at temperature

- Electrical interference - usually from heater or motor wiring running very close to the temperature sensor wiring. Generally shows when machine is operating

- Power supply issues - faulty or failing power supply, external power spikes (eg large/noisy dc motor on the same electrical circuit starting/stopping)

- Hardware issues - faulty Duet board. Try connecting the PT1000 to the other temperature input on the 1LC, or move the temperature sensor and heater to the mainboard to test

- Firmware bug - least likely because this is heavily tested, and would be reported by other users.

Ian

-

@Arminas said in PT1000 thermistor configuration:

erature is stable all the time, expect at a

you probably have season changes and thus your PID tuning is out the window.

rerun the tune and you will probably find that it works fine now