Correct steps per mm for Z axis to move 1mm

-

Any Quick suggestions:

On my PnP Machine, i have 3 x NEMA 17 steppers Motors BD4248 with 1.8 deg./step , 200 KHz used for 3 x Z-axes type ( Z, U, V) on Duet 3HC using Duet Internal (In-built) Drivers

-

5mm (0.2") Diameter Drive Shaft . i.e The circumference = 1 complete revolution (360 degrees) = 15.71 mm

-

360/1.8 = 200 steps/revolution

-

So steps/mm on Z-axes = 200/15.71 steps/mm = 12.73 steps/mm

i think i might be calculating it wrong ???

My goal is to have OpenPnP synchronized with Duet3 Controller board so an OpenPnP command for Z axis to move 1mm actually moves 1mm on the Z-axis on the machine

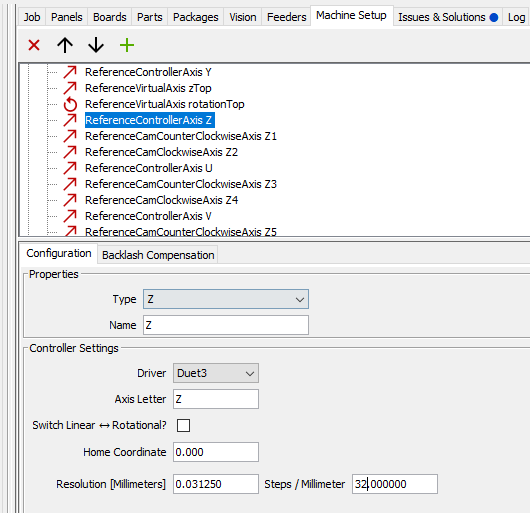

My Current Z-axes configs on Duet3 Controller that need adjustment

M584 Z1.0 U1.1 V1.2 R0 S0 ; LIN R0 = LINEAR , R1 = ROTATION M350 Z32 U32 V32 I1 ; configure microstepping with interpolation M92 Z32 U32 V32 ; set steps per mm M566 Z900.00 U900.00 V900.00 ; set maximum instantaneous speed changes (mm/min) M203 Z60.00 U60.00 V60.00 ; set maximum speeds (mm/min) M201 Z60.00 U60.00 V60.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeoutMy OpenPnP Configs

Any help or pointers ?

-

-

@developeralgo222 Normally you do not need to know the diameter of the motor shaft as it has nothing to do with the steps/mm. Are you using lead screws? Lead screws will have a spec called "lead" which is the linear distance the nut (your Z axis) would move in one full rotation. For one-start lead screws, lead is the same as pitch. For two-start screws, lead is 2x the pitch, etc. Lead/200 = full steps per mm. If you turn on microstepping you also have to multiply by the microstepping factor.

If you're using lead screws and they are connected with a belt to a single motor, you also have to factor in the pulley size ratios.

-

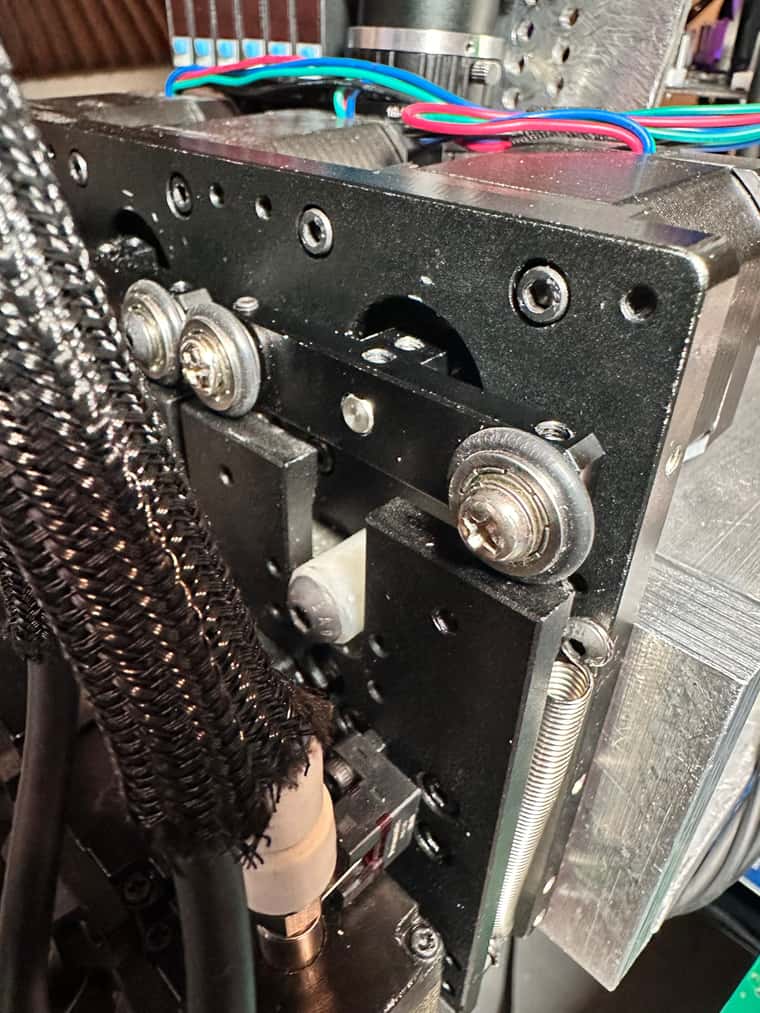

It just Stepper motor which is CAM driven, no belts or no leadscrew

-

So the Z axis movement is just the motor turning a cam to raise or lower a small amount? Is that what you're showing in your second photo?

-

@developeralgo222 from the responses on the OpenPnP group at https://groups.google.com/g/openpnp/c/W-ZLi_xXj-A it appears to me that you need to specify the microsteps/degree for a cam-driven Z axis, not steps/mm.