SZP for bed level in 3.6-RC1

-

@gloomyandy thanks for the reply!

The probe is around 2mm above the nozzle tip. I can only move it about another 1mm higher relative to the nozzle without some redesign. Since my last post I had change the G31 to Z3 because that was what I got when I did a G30 K1 S-1. I'm really not clear how the trigger height is getting established. Am I requesting a height to trigger and then M558.1 is finding the right threshold to trip it? What is the purpose of overshooting the limit with S parameter? When I was setting 2mm before it tripped at 3mm.

While debugging this I realized that although the bed can potentially have a large tilt to it, it is mostly in negative. The high initial dive was to prevent crashes on first pass. But due to the bed probe at the back of the bed, the front cannot be more than ~7 mm higher so I set the first dive to 10mm now. So the SZP will cover less range now.

I don't understand the DWC feedback. I was seeing red Z values for heights above the trigger, like 6mm. And sometimes I see yellow. Right now it is behaving.

My config was about 4 years old, which I based off someone else. So this overhaul for CAN is finding a lot of things to fix. I have no idea how the bed level was working before because you are correct I am missing the A parameter. It was doing 3x probes at each point. And right before I switched to CAN I added the second dive height since that had been introduced in the intervening years and it did both heights but only once each. Now it is only doing 1 which makes sense based on command.

I am currently trying to get mesh.g to work but it fails every time on the first point with an error that I need to recalibrate the probe, despite the ABL working correctly now. The G29 starts with a high Z value that I cannot seem to control.

-

@jltx said in SZP for bed level in 3.6-RC1:

I don't understand the DWC feedback. I was seeing red Z values for heights above the trigger, like 6mm. And sometimes I see yellow. Right now it is behaving.

Are you sure it was red when that far above the trigger height? That is not normal unless the probe is returning an invalid reading (in which case it will read 99999). The colour will change as you get close to the trigger threshold. Had you actually set the trigger threshold when you saw the DWC reading go red? You can find out what the current trigger height and threshold are by running G31 k<probe number> with no other parameters.

The threshold is set either by using the P parameter to G31, when you do that you are basically saying set the trigger threshold to be <xxxx> (the P parameter value) and that this value will be reported at the Z height set with the Z parameter of G31. The alternate way to set the threshold with a SZP is to set the Z trigger height with G31 and then to use M558.1 to run a calibration pass. This will move to the Z trigger height plus the calibration range set by the M558.1 S parameter and will then move down to the trigger height minus the calibration range, taking a series of readings. This data is then used to calibrate the conversion of readings to actual height above the bed. As part of the process the probe trigger threshold will also be set to match the trigger height.

I am currently trying to get mesh.g to work but it fails every time on the first point with an error that I need to recalibrate the probe, despite the ABL working correctly now. The G29 starts with a high Z value that I cannot seem to control.

What is the full error message you are getting when you try to perform the scan? You probably need to post your updated bed.g and mesh.g files so we can see what it is you are doing.

After running ABL you should rehome Z and probably recalibrate the SZP using M558.1 then run the scan using G29, this scan will move the probe to the trigger height as set by G31 and will then perform the scan. So you need to be sure that that drive current is set to ensure that you have valid readings with the nozzle at the selected trigger height and at all heights above/below this needed to obtain a scan.

-

@gloomyandy said in SZP for bed level in 3.6-RC1:

Are you sure it was red when that far above the trigger height? That is not normal unless the probe is returning an invalid reading (in which case it will read 99999). The colour will change as you get close to the trigger threshold. Had you actually set the trigger threshold when you saw the DWC reading go red?

The trigger threshold is set in my config.g so always set. It is possible there was a lag on display update, i.e. last point red, next point should not be but still red. I don't have a computer near the printer, I only have 12864 so I use my phone for DWC if I am debugging live with the printer.

The alternate way to set the threshold with a SZP is to set the Z trigger height with G31 and then to use M558.1 to run a calibration pass. This will move to the Z trigger height plus the calibration range set by the M558.1 S parameter and will then move down to the trigger height minus the calibration range, taking a series of readings. This data is then used to calibrate the conversion of readings to actual height above the bed. As part of the process the probe trigger threshold will also be set to match the trigger height.

This is how I thought it worked. But I had the experience above where I had G31 Z2 and then later after an M558.1 I ran a G30 K1 S-1 and it triggered at 3.06 mm. So that convinced me I have not idea what is going on. But now it is behaving more like I would expect.

I am currently trying to get mesh.g to work but it fails every time on the first point with an error that I need to recalibrate the probe, despite the ABL working correctly now. The G29 starts with a high Z value that I cannot seem to control.

What is the full error message you are getting when you try to perform the scan? You probably need to post your updated bed.g and mesh.g files so we can see what it is you are doing.

Well once again, with no changes, I turn on printer today and the same g file works. The scan was crazy slow though, 1mm/s. So I then added the M558 K1 F20000 and it scans quickly now. I think I was on the edge of a good drive current yesterday and today it likes it. Another thing I have noticed is that certain parameters are sticky. For example, I went back and added an A2 to one of my bed level probes. And after that all were doubled, every time. So it is possible I had set something during debug through the console that stuck and cause havoc with G29. Here is the mesh.g in case you see something wrong.

G32 M561 ; ignore current heightmap G29 S2 ; Disable mesh bed compensation ; Establish final Z ref ;M291 P"Final Z ref..." R"Bed Mesh" T5 G28 Z ; Ensure Z is higher than inductive probe trigger height G1 Z6 ; To avoid backlash move to point higher than start of calibration ; Get the reference Z offset M98 P"/macros/print_scripts/goto_bed_center.g" M558.1 K1 S1.7 ; Calibrate probe G1 Z6 ; Move up at end of calibration ; Probe a new bed mesh! ;M291 P"Probing now!" R"Bed Mesh" T5 M558 K1 F20000 ; set probe feed rate G29 S0 K1 ; Scan bed and create mesh -

@jltx said in SZP for bed level in 3.6-RC1:

The trigger threshold is set in my config.g

Please post your config.g file so we can see what you are setting.

-

; Configuration file for Duet 3 Mini 5+ with SBC and Roto Toolboard (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sat Jun 05 2021 22:48:46 GMT-0500 (CDT) ; General preferences M111 S0 ; Debugging off G21 ; Work in millimetres G90 ; send absolute coordinates... M83 ; ...but relative extruder moves G4 S2 ; wait for expansion boards to start ;now goes into dsf-config.g -> M550 P"CerberusDWC" ; set printer name M669 K1 ; select CoreXY mode M564 S1 H1 ; Forbid axis movements when not homed ; Network ;SBC M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; --- Drive map --- ; B _______ A ; | 2 | ; Z | 1 | 0 | ; ------- ; front ; ; (looking at the printer from the top) ;Crown lights M950 E0 C"led" T1 ;Q3000000 ; set LED type to NeoPixel and set SPI frequency to 3MHz M150 E0 B255 P192 S30 F0 ; set next 20 LEDs to cyan, full brightness, finished programming strip ; Drives M569 P0.0 S1 ; A drive 0.0 goes forwards M569 P0.1 S1 ; B drive 0.1 goes forwards M569 P0.2 S0 ; Z0 drive 0.2 goes backwards M569 P0.3 S0 ; Z1 drive 0.3 goes backwards M569 P0.4 S0 ; Z2 drive 0.6 goes backwards M569 P121.0 S1 ; E drive 0.4 goes forwards ; motor mapping and steps M584 X0.0 Y0.1 Z0.2:0.3:0.4 E121.0 ; set drive mapping ;M584 U0.2 V0.3 W0.6 ;control individual Z M350 X4 Y4 Z16 E16 I1 ; configure microstepping with interpolation M92 X40.00 Y40.00 ; set steps per mm (0.9deg) M92 Z800.00 E688.00 ; set steps per mm (1.8deg) ; drive currents M906 X1400 Y1400 Z1200 E1150 I20 ; set motor currents (mA) and motor idle factor in per cent M84 S60 ; Set idle timeout ; Accelerations and speed M98 P"/macros/print_scripts/setup_printing.g" ; Axis Limits M208 X-1 Y-2 Z-0.5 S1 ; set axis minima M208 X302 Y307 Z260 S0 ; set axis maxima ; Bed mechanics M671 X345:-45:150 Y20:20:345 S12 ; bed pivot coords, max 12mm adjust ; Endstops M574 X2 S1 P"121.^io1.in" ; configure active-high endstop for high end on X via pin ^io1.in M574 Y2 S1 P"^io4.in" ; configure active-high endstop for high end on Y via pin ^io2.in M574 Z0 P"nil" ; No Z endstop ; Z probes ;old inductive probe M558 K0 P8 C"^io5.in" T24000 F120 H5 A5 S0.01 R0.2 ;old inductive probe G31 K0 P500 X0 Y25 Z2.48 ; Don't really care about inductive probe Z offset M558 K0 P8 C"^io6.in" T15000 F240:60 H2 A6 S0.005 R0.2 ; microswitch bed offset probe ;G31 K0 P500 Z0.819 S25 T-0.0012:0 H2 ; Z switch offset @ 25C (if positive, greater value = nozzle closer to bed. if negative, more negative = nozzle further from bed) G31 K0 P500 Z-0.056 ; use fixed value for now ; Scanning Z probe M558 K1 P11 C"121.i2c.ldc1612" F36000 T36000 ; configure SZP as probe 1, type 11, on CAN address 120 M308 A"SZP coil" S10 Y"thermistor" P"121.temp2" ; thermistor on SZP coil G31 K1 X0 Y36 Z3 ; define probe 1 offsets and trigger height M558.2 K1 S16 R120000 ; set drive current and reading offset ; Bed heater (dual thermistor setup) M308 S0 P"temp0" Y"thermistor" T100000 B3950 A"Bed Heater" ; configure sensor 0 as thermistor on pin temp0 (heater sensor) M308 S2 P"temp2" Y"thermistor" T100000 B3950 A"Bed Plate" ; configure sensor 2 as thermistor on pin temp1 (mic6 sensor) M950 H0 C"out0" T0 Q10 ; ##FIXME create bed heater output on out0 and map it to sensor 2 (mic6 sensor). Set PWM frequency to 10Hz M140 P0 H0 ; Mark heater H0 as bed heater (for DWC) M143 H0 P1 T0 A2 S120 C0 ; Regulate (A2) bed heater (H0) to have pad sensor (T0) below 115°C. Use Heater monitor 1 for it M143 H0 P2 T0 A1 S125 C0 ; Shut off (A1) bed heater (H0) if pad sensor (T0) exceeds 125°C. Use Heater monitor 2 for it M143 H0 S120 ; Set bed heater max temperature to 110°C, use implict monitor 0 which is implicitly configured for heater fault M307 H0 B0 S0.6 ; disable bang-bang mode and set PWM to 60% to avoid warping ; Hotend heater M308 S1 A"Hotned" P"121.temp1" Y"pt1000" ;R2200 ; configure sensor 1 as PT1000 on pin temp1 M950 H1 C"121.out0" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S350 ; set temperature limit for heater 1 to 350C ; MCU sensors (not available on Mini5+, Booh!!) ;M308 S3 Y"mcu-temp" A"MCU" ;M308 S4 Y"drivers" A"Drivers" ; chamber temp+humid M308 S10 P"io1.out+io1.in" Y"dht22" A"Chamber Temp[C]" ; Set DHT22 for chamber temp M308 S11 P"S10.1" Y"dhthumidity" A"Chamber Hum[%]" ; Fans M950 F0 C"121.out2" Q250 ; create fan 0 (hotend) on pin out4 and set its frequency M106 P0 S1 H1 T50 C"Hotend" ; configure fan 0 value. Thermostatic control is turned on, using sensor #1 M950 F1 C"121.out1" Q20 ; create fan 1 (cooling) on pin out3 and set its frequency M106 P1 S0 H-1 C"Cooling" ; configure fan 1 value. Thermostatic control is turned off M950 F2 C"out3" Q150 ; Create fan 2 (electronics bay) on pin out5 and set its frequency ;;M106 P2 S0.25 H1 T50 C"BedFan" ; Run the fans at 25% if the hotend is over 50C M106 P2 S0 H-1 C"BedFan" ; (temporary manual setup) M950 F3 C"out4" Q150 ; Create fan 3 (chamber) on pin out6 and set its frequency ;M106 P3 S1 H2 T65 C"Bento" ; Configure fan 3: Thermostatic control is turned on, based on sensor #2 (mic6 temp) M106 P3 S0 H-1 C"Bento" ; (temporary manual setup) -

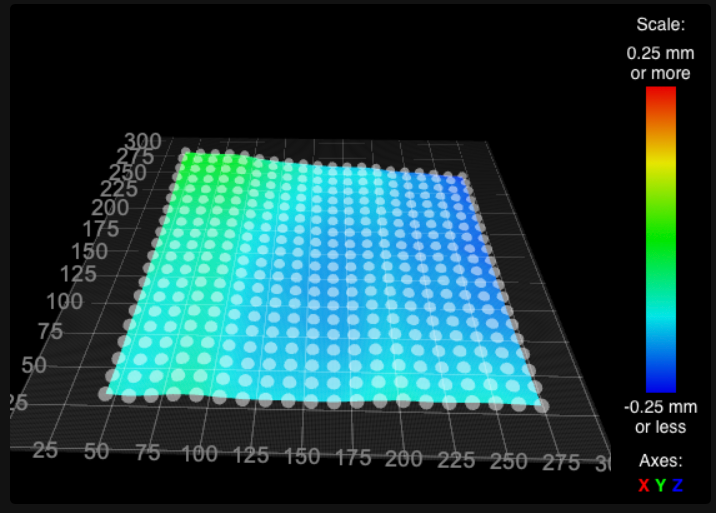

since I recalibrate probe at bed center, should't that point come back as zero in the bed mesh? I am not seeing that.

-

@jltx answering my own question: no. The Z reference is the rear probe (K0) and so bed center can be offset.

-

@jltx said in SZP for bed level in 3.6-RC1:

G31 K1 X0 Y36 Z3 ; define probe 1 offsets and trigger height

M558.2 K1 S16 R120000 ; set drive current and reading offsetYou are not setting the probe threshold/trigger value in config.g (the P parameter to G31), so it will be using whatever the default is (which is almost certainly not correct) until you have performed a M558.1.

As to the mesh not reading zero at the centre of the bed. I would expect the scan to return 0 for wherever you have homed/set Z=0, ideally you will be homing and calibrating the probe at the same location, which again is ideally probably in the centre of the bed. I don't think you have posted your homez.g file so I'm not sure what you are doing to set z=0. Depending upon how you are setting Z=0 you may need to adjust the position of the nozzle to place your szp coil over the same location used to set z=0 before carrying out the calibration of the szp.

-

@gloomyandy said in SZP for bed level in 3.6-RC1:

You are not setting the probe threshold/trigger value in config.g (the P parameter to G31), so it will be using whatever the default is (which is almost certainly not correct) until you have performed a M558.1.

Correct. You can't guess this value so it would just be a random number. Before any use of the SZP I run a M558.1, such as in bed.g and mesh.g.

As to the mesh not reading zero at the centre of the bed. I would expect the scan to return 0 for wherever you have homed/set Z=0, ideally you will be homing and calibrating the probe at the same location

correct. I answered myself above when I remembered I am setting Z=0 with a separate probe at the back of the bed. So the bed scan does not necessarily cross zero, especially if the G31 offset for that probe isn't close enough.

Everything seems to be running well. I don't know why I had so much trouble setting it up. I understood the documentation but thought that I didn't because the results were so flaky. Knock on wood but it is stable right now. It is a very slick setup and much better than what I had before. Thanks for the help.

-

undefined droftarts has marked this topic as solved

undefined droftarts has marked this topic as solved