Problem with external stepper drivers

-

It sounds to me that your T parameter is still too low. Try T5. Also check that you have the correct driver numbers in the M569 commands.

-

Tested with T5 and T10, nothing change, the problem continue

Problem happen in X Y and Z -

Please provide a link to the datasheet for those drivers. Also post your config.g file.

-

Datasheet:

https://forum.linuxcnc.org/media/kunena/attachments/1749/2m982.pdfConfig:

[[language]] ; Configuration file for Duet WiFi (firmware version 1.20 or newer) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool on Wed Mar 14 2018 18:47:26 GMT+0100 (CET) ; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves ; Network M550 PMyPrinterName ; Set machine name M552 S1 ; Enable network M587 S"CNC" P"JJ393267652NHHJHJHHK" I192.168.2.202 J192.168.2.1 K255.255.255.0 ; Configure access point and IP addresses. You can delete this line once connected M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Drives M569 P0 S1 T2 ; Drive 0 goes forwards M569 P1 S1 T2 ; Drive 1 goes forwards M569 P2 S1 T2 ; Drive 2 goes forwards M569 P3 S0 ; Drive 3 goes backwards M569 P4 S1 ; Drive 4 goes forwards M584 X7 Y6 Z5 E3:4 ; Apply custom drive mapping M350 X16 Y16 Z16 E16:16 I0 ; Configure microstepping without interpolation M92 X160 Y160 Z320 E504:504 ; Set steps per mm M566 X60 Y60 Z18 E120:120 ; Set maximum instantaneous speed changes (mm/min) M203 X4500 Y4500 Z1500 E6000:6000 ; Set maximum speeds (mm/min) M201 X100 Y100 Z100 E1000:1000 ; Set accelerations (mm/s^2) M906 X800 Y800 Z800 E1000:1000 ; Set motor currents (mA) M84 S0 ; Disable motor idle current reduction ; Axis Limits M208 X0 Y0 Z0 S1 ; Set axis minima M208 X1150 Y800 Z500 S0 ; Set axis maxima ; Endstops M574 X1 Y1 S0 ; Set active low endstops M558 P0 H5 F120 T6000 ; Disable Z probe but set dive height, probe speed and travel speed M557 X15:1085 Y15:785 S20 ; Define mesh grid ; Heaters M305 P0 T100000 B4725 C7.060000e-8 R4700 ; Set thermistor + ADC parameters for heater 0 M143 H0 S300 ; Set temperature limit for heater 0 to 300C M305 P1 X150 ; Configure thermocouple for heater 1 M143 H1 S300 ; Set temperature limit for heater 1 to 300C ; Fans M106 P0 S0.1 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 S0.5 I0 F500 H T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on M106 P2 S0.5 I0 F500 H T45 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Tools M563 P0 D0 H1 ; Define tool 0 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C M563 P1 D1 H1 ; Define tool 1 G10 P1 X0 Y0 Z0 ; Set tool 1 axis offsets G10 P1 R0 S0 ; Set initial tool 1 active and standby temperatures to 0C ; Automatic saving after power loss is not enabled ; Custom settings are not configured ; Miscellaneous T0 ```// I see than you do some changes in the 1.21RC for external stepper drivers, maybe is for this? I use 1.20. -

Tested in 1.21RC4 and happen the same

-

You have the driver numbers as 0, 1, 2 in your first three M569 commands, so the T2 parameter is being applied to the internal drivers, not the external drivers. Your M584 command maps XYZ to drivers 7, 6 and 5. So the P parameters in those M569 commands need to be 5, 6 and 7 not 0, 1 and 2.

-

Tested and works!!!

Two questions:- My correct value is supposed than is T2.5? or biggest?

- Is working…. Taa:bb:cc:dd?? (you say: planned for a future firmware version)

-

One thing….

Axis X and Y works perfect, but Z not.

Axi Z have same stepper driver but.

My table is moved for 4 stepper, each stepper use one driver.

The four drivers is connected to E4 output PUL/DIR.

Perhaps is for this? -

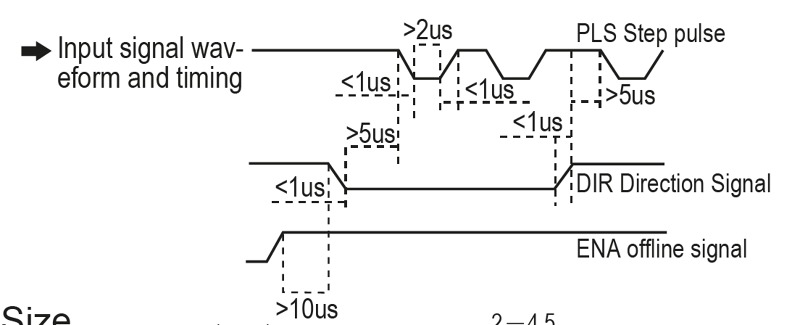

Your drivers require a 5us setup time from DIR changing to the leading edge of STEP, so it would be best to use T5 at present.

The Taa:bb:cc:dd syntax is implemented in firmware 1.21RC5 which I hope to release tomorrow, perhaps even tonight. Then you should be able to use T2.5:2.5:5:0.

-

You are true, tested with 5 and is ok, tested with 10 and is ok.

What will be the difference between use 5 or 10?Thanks for everything.

-

The higher the T value you use, the lower the maximum step rate will be and the more CPU time it will use in generating step pulses. This may affect the maximum microstepping that you can set those drivers to.

-

Only want question more (sorry but this discuss is really interesting….)

-What Steps/rev you advise? 1600-3200... or that? -

3200 or 6400 would be typical values. The limiting factor is the step pulse rate at the highest speed that you want the motors to move.

-

With the new RC5 is necessary totally configure the M569,

so the correct is T2.5:2.5:5:0? (like you say in the old post)Minimum driver step pulse width: 2.5

Step pulse interval: 2.5

Direction setup time: 5

Direction hold time: 0Regard to the draw of my external stepper driver:

???

I think than the correct is:

Minimum driver step pulse width: 2

Step pulse interval: 5

Direction setup time: 1

Direction hold time: 1

T2:5:1:1 -

That diagram doesn't give the minimum step interval, so you need to work it out from the maximum step rate quoted on the data sheet. The second T parameter is the minimum interval between the end of one step pulse and the start of the next.

-

So, You advise me use this:

T2.5:2.5:5:0Minimum driver step pulse width: 2.5

Step pulse interval: 2.5

Direction setup time: 5

Direction hold time: 0??

-

If the maximum step pulse rate is 200kHz, then yes.