Duet resetting with high motor currents

-

Hi there!

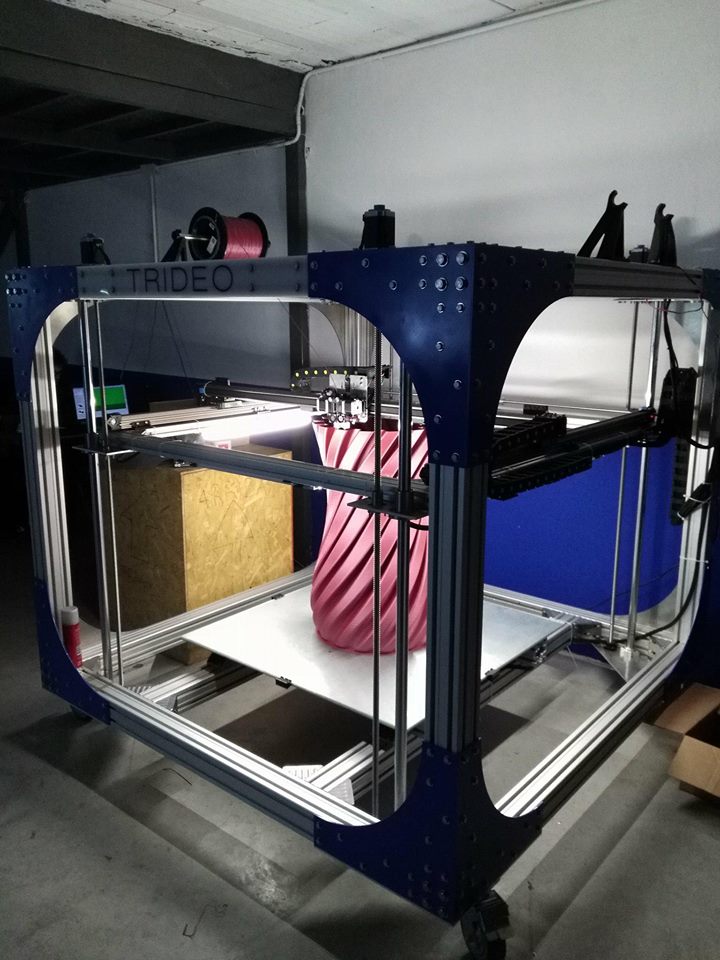

We have just finished our first 1 cubic meter printer using DUET board + DUEX5 + PANEL, we are very happy and satisfied using duet for that new printer!

However, we experienced some issues : we are using six nema 23 2.8A motor current for all axis (except for Extruders) , divided as shown below:

M584 X0 Y1 Z6:7:8:9 E3:4

M350 X32 Y32 Z32 E16:16 I0

M92 X85 Y85 Z1280 E405:405

M566 X900 Y900 Z12 E120:120

M203 X18000 Y18000 Z360 E1200:1200

M201 X500 Y500 Z250 E250:250

M906 X1680 Y1680 Z1680 E800:800 I30We started our experiments with 60% nominal current = 1680mA for each motors, but when we turned on all motors and then heated up the extruder the board reseted and gave us " cause: reset button or watchdog" error message. (heated bed not taken into account because directly fed from 220V).

Everything works well using 40% nominal current = 1120mA, we already did some prints like this but we seriously think that we have a lack of torque.

Our configuration :

- Firmware 1.21

-24V 15A leds power supply (could be the responsible)

Thanks for your help, any question about the printer just ask.

Simon

- Firmware 1.21

-

It does sound like a power issue. The first thing to check is that the VIN terminal block screws are tight.

When using a DueX5 it is vital that the ground connection between the Duet and the DueX5 VIN terminal blocks is thick and very short. This is especially important when using high motor currents. Can you post a photo showing the VIN wiring?

-

@trideo 6 steppers at 1.12A imply a total of almost 7A, but that is RMS! For that the peak current can be as high as 10A (roughly 1.4*RMS).

To that you must add the current required by the extruders, again considering the above rule. From your configuration values I see 0.8A for each extruder, and that gives about 1.15A peak current, so you can have as much as 2.3A for both extruders.

At 12.3A there is little margin in the PSU, if any at all, because the Duet boards and the panel also need some power and, of course, you have mentioned nothing about the heaters on the printing heads.

Based on your findings, you have about 5.5A power requirement of everything else except the NEMA23 steppers. With 2.8A steppers, you could go as high as 2.24A limit in Duet configuration, thus needing roughly 19A for all of them. So a 25A PSU is the minimum I would consider. And use some thick cables between the PSU and Duet boards. 1.5sqmm ones are the minimum I would consider, but for safety I would go for thicker ones, like 2.5sqmm, especially to reduce voltage drop as much as possible at those currents.

-

Actually the current drawn by the stepper drivers from the 24V VIN supply is very much less than the current in the motors, except during high speed acceleration. That's the magic of chopper-type stepper motor drivers. So a 15A supply should be more than enough.

I suspect the problem is caused by the ground wire between VIN on the Duet and on the X5 being too long or too thin.

-

Indeed, it is usually a lot less. But it may happen to have just now and then all motors in a state that briefly requires that high current. The PSU overload protection could easily trigger. @Trideo mentioned that the problem is visible when he activates all motors and starts heating the extruder. On my WorkBee there is a strong mechanical "bump" just before doing the first homing cycle, after powering it up. The 4 steppers are rated for 3A, set to 2.4A in firmware. There is a significant current surge visible even on the 220V input of the PSU during the initial "bump". And I have a 24V/20A MeanWell PSU. Previously I had a 13A one (leftover from previous eShapeOko) and it wasn't really coping with the startup current.

While I agree with you on the relatively low current needed when moving, that is true for 3D printing, and only when the printing head is low weight. So far we know nothing related to @Trideo's printer, but I assume that those NEMA23 steppers have been chosen for a reason! And if the printer works at 40% of the rated current, that doesn't mean that smaller steppers could have done the job equally well - for the same current the torque would have been significantly lower.

@Trideo mentions that the PSU is built for LEDs. From my own experience it is not a good choice because the load impedance is different when supplying steppers, and it gets worse with large steppers.

As for grounding, I agree that it must be properly done. But I would also recommend to use shielded cables for steppers and home/limit switches, with the shield connected to ground near the Duet. If the radiated electrical noise is too high, it may trigger random resets even if everything else is properly done. With 1 cubic meter printer, some of the stepper cables are quite long for sure.

-

@dc42 said in Duet resetting with high motor currents:

uspect the problem is caused by the ground wire between VIN on the Duet and on the X5 being too long or too thin

Hi everybody,

First off all thank you very much for your support guys, so quick!

@dc42 you were right! We badly wired the due5x, we connected it directly from power supply, sorry for that. As soon as we wired it the right way the printer started working normally with 60% motors current. To be confirmed after some prints.- all motors are over-sized, mainly those for Z axis

- Led supply will by replaced for commercial printers (LATAM market, mostly Argentina and Brasil)

- Shield cable everywhere for commercial printers.

I'm a bit confused about you guys speaking about neutral and ground connection. Are you talking about the 2 power-in connections (VIN and GND) on both of the boards ?

We are in Argentina, unfortunately we don't have access to every component we would like to use, it's a difficult country for hardware businesses...and we are a little startup, but we get a duet board!

Sorry for my bad English and thank you once again.

A printer picture last night

-

@trideo First of all a big

for the build! Those square profiles seem at least 60x60mm (when compared to the potentially 20x20 profile used as bed frame) and mechanically it looks quite robust. Of course that comes with some weight, but clearly not enough to bother the NEMA23 steppers even at 40% current! I see that the Z axis steppers are moving the gantry, so their load is constant and pretty low. On my eShapeOko I had a small Nema17 and it could raise a 2.5kg gantry (milling spindle, spindle fixture, Z axis, stepper, leadscrew etc.), and I don't think your gantry is weighing 10kg or more.

for the build! Those square profiles seem at least 60x60mm (when compared to the potentially 20x20 profile used as bed frame) and mechanically it looks quite robust. Of course that comes with some weight, but clearly not enough to bother the NEMA23 steppers even at 40% current! I see that the Z axis steppers are moving the gantry, so their load is constant and pretty low. On my eShapeOko I had a small Nema17 and it could raise a 2.5kg gantry (milling spindle, spindle fixture, Z axis, stepper, leadscrew etc.), and I don't think your gantry is weighing 10kg or more.Looking further into the picture, you have a Cartesian printer. So the moving gantry has a large stepper on it for the other axis (X or Y, doesn't really matter for the discussion) and the extruder(s).

In the end the large NEMA23 are quite an overkill, largest NEMA17 would have been more than enough for sure! But, please, don't think that I'm trying to criticize you, as I did exactly the same when ordering my WorkBee - I have selected the highest torque steppers available (not really sorry about that as I'm going to upgrade the spindle and that is bringing extra weight)!

I hope that when you say "commercial printers" you are actually meaning "commercial 3D printers"! A PC printer (laser/ink jet) has a different PSU requirements when compared to a 3D printer as it has less (none in some cases) steppers and some resistive loads from the heaters!

I personally use LAPP Kabel shielded cables with 2 and 4 cores (available at Farnell/Newark, for example). The shield is connected to the Earth connection of the wall socket (through the PC PSU-like cable!) and the cores are used for connecting the steppers or the home/limit switches. The new spindle will be a 800W air cooled induction motor and the shield will be grounded by the Duet board, with the 4 cores being for for ground connection of the spindle and the three phases of the induction motor.

As far as 220V AC (or whatever you have in there!) is considered, it normally has three wires - Phase (this is the "hot" one), Neutral and Earth/Ground. Phase and Neutral are for "energy carrying" and the Neutral is just a common voltage reference (when PC networking was done using RG58 cable, at 10Mbps, if you were trying to connect two networks supplied from different 380V/AC phases, without properly wired ground connections, most of the times you would have ended up buried into the wall across the room). If any of the current normally going through the phase and neutral wires gets into the ground wire, a decent differential protection would trigger. When we are talking about DC, GND should be connected to Earth ground connection.

Cable shielding, when connected to the ground, almost creates a Faraday cage around the cores, thus reducing to minimum the radiated energy and the interference from external sources. For a power supply cable, even if the shield the ground wires are connected at the same point, on one end, the ground cable is the return path for the supply current and the shield is just a Faraday cage. Trying to use the cable shield for closing a current loop is not better than using shielded cables, actually being worse in many scenarios!

Those being said, the radio guy will remain silent for a while!

-

@trideo said in Duet resetting with high motor currents:

@dc42 said in Duet resetting with high motor currents:

uspect the problem is caused by the ground wire between VIN on the Duet and on the X5 being too long or too thin

Hi everybody,

First off all thank you very much for your support guys, so quick!

@dc42 you were right! We badly wired the due5x, we connected it directly from power supply, sorry for that. As soon as we wired it the right way the printer started working normally with 60% motors current. To be confirmed after some prints.We are in Argentina, unfortunately we don't have access to every component we would like to use, it's a difficult country for hardware businesses...and we are a little startup, but we get a duet board!

I'm glad you solved it. That's a lovely looking printer!

-

Hi guys,

Thank you for all the informations, sorry we're late to answer but we were working a lot on our 3d printer, we're still experiencing some troubles, but nothing very disturbing.

@Catalin_RO thanks for all the clarifications on what cable you use and your explaination. We are currently working on changing the wiring of the printer to put some bigger shielded cable and ground everything the right way. As you said, using Nema23 is more than enough to move our gantry, and as you pointed we have more than enough torque, so for the next machine it will be open to amelioration on choosing better motors.

Again, thanks, that's very nice to see that people care about other's problems and respond very quickly !

All the best,

Team Trideo