Scalloping Issue

-

Quick Machine Specs:

CR-10 Custom Clone

Dual extruders with steppers on x carriage

Standard 16 microstep with interpolation

Running V1.19 FirmwareI have a very peculiar issue with my 3d printer I just finished building, (Pics, vids, and CAD files coming soon in another topic) where on some STL files I am getting a scalloping effect where the lines between wall points are concave and very noticeable.

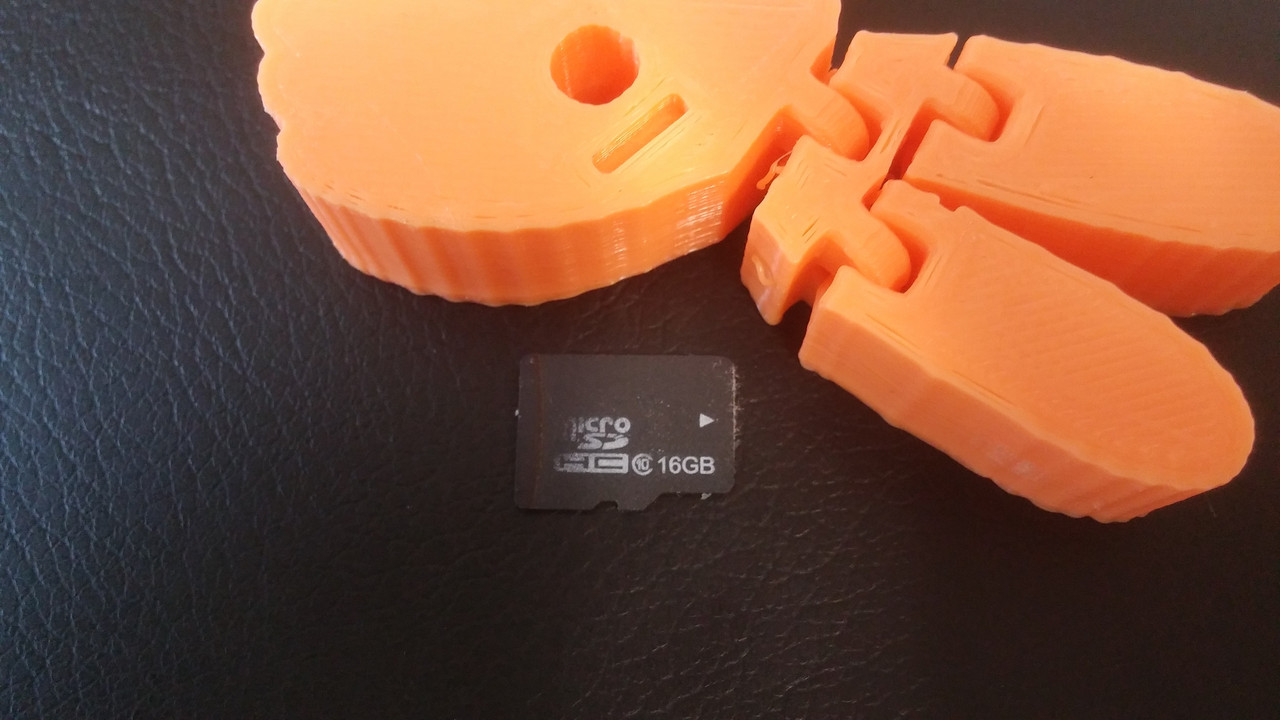

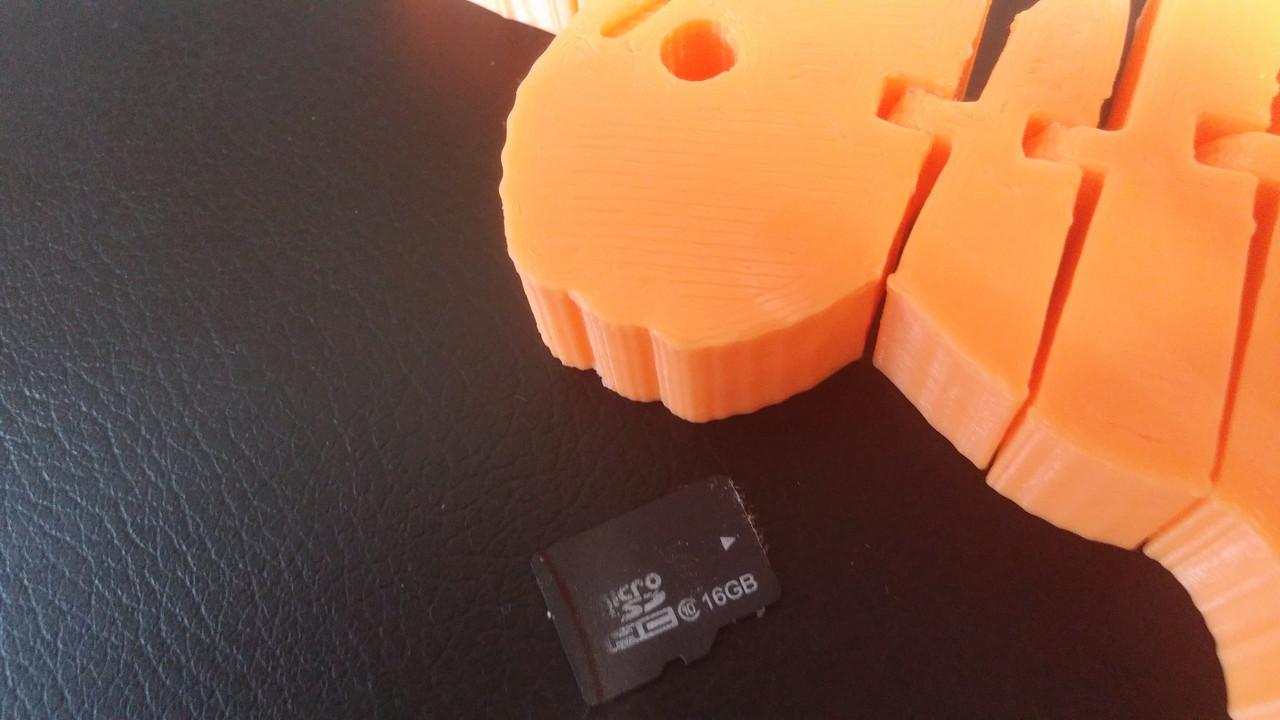

Here are some pics regarding what I am talking about. For reference the Bunny is downloaded from Thinigiverse and I would assume is a somewhat low poly count figure, while the Shark is my own creation and is of the highest poly quality Fusion 360 allows.

MicroSD card included for scale.

The shark which shows no scalloping and nice smooth curves.

The bunny showing severe scalloping between wall pointsAlso note in the next picture that the scalloping scale changes in proportion to the curve radius.

Scalloping gets tighter around mouth/nose where curve radius tightens.Based on the fact that it was able to produce smooth curves on the shark I am very confident mechanical problems are not part of this issue. I am inclined to think it is something to do with the interpolation on the steppers but idk.

The bunny STL is available at https://www.thingiverse.com/thing:2832177

The shark STL is available at https://www.thingiverse.com/thing:2804703

Both were printed with the exact same Cura settings, and no firmware setting changes either.

My next troubleshooting question is really should I be looking at the Duet or Cura for this issue because when I preview the gcode files I don't see the scalloping that results. (Making me think it's the Duet)

Let me know if you would like me to post more info such as config.g or Cura settings.

Thank you in advance. Excellent product the Duet is, I am just so happy with my purchase.

-

Now that I am thinking about it I know you'll want to know my speed settings as I am starting to think I may have my instantaneous accel (jerk) too low. Here is my config with password redacted obviously.

; Configuration file for Duet Ethernet (firmware version 1.17 to 1.19)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool on Sat Apr 21 2018 08:39:01 GMT-0400 (Eastern Daylight Time); General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves; Network

M550 PJP-440 ; Set machine name

M551 Phahahahnoway ; Set password

M540 PIN:VA:LI:DE ; Set MAC address

M552 P0.0.0.0 S1 ; Enable network and acquire dynamic address via DHCP

M586 P0 S1 ; Enable HTTP

M586 P1 S1 ; Enable FTP

M586 P2 S1 ; Enable Telnet; Drives

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S0 ; Drive 1 goes backwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S0 ; Drive 3 goes forwards

M569 P4 S1 ; Drive 4 goes backwards

M350 X16 Y16 Z16 E16:16 I1 ; Configure microstepping with interpolation

M92 X79.635 Y80.2 Z395 E164.4:164.4 ; Set steps per mm

M566 X54 Y54 Z100 E180:180 ; Set maximum instantaneous speed changes (mm/min)

M203 X6000 Y6000 Z400 E4800:4800 ; Set maximum speeds (mm/min)

M201 X300 Y300 Z1900 E1080:1080 ; Set accelerations (mm/s^2)

M906 X1200 Y1360 Z1200 E1100:1100 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X-63 Y-8 Z.25 S1 ; Set axis minima

M208 X352 Y377 Z385 S0 ; Set axis maxima

; Endstops

M574 X1 Y1 Z1 S0 ; Set active low endstops; Heaters

M305 P0 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M305 P1 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S280 ; Set temperature limit for heater 1 to 280C

M305 P2 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 2

M143 H2 S280 ; Set temperature limit for heater 2 to 280C; Fans

M106 P0 S0 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S0 I0 F500 H-1 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P2 S0 I0 F500 H-1 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned off; Tools

M563 P0 D0 H1 F1:2 S"Left Extruder" ; Define tool 0

G10 P0 X28.5 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C

M563 P1 D1 H2 F1:2 S"Right Extruder" ; Define tool 1

G10 P1 X59.15 Y0.46 Z0 ; Set tool 1 axis offsets

G10 P1 R0 S0 ; Set initial tool 1 active and standby temperatures to 0C; Custom settings are not configured

-

@hpiz said in Scalloping Issue:

M566 X54 Y54

That's very very low for jerk. Remember, it's mm/min not mm/s.

Try a value of 500 or so.

-

@phaedrux said in Scalloping Issue:

@hpiz said in Scalloping Issue:

M566 X54 Y54

That's very very low for jerk. Remember, it's mm/min not mm/s.

Try a value of 500 or so.

You're right, I was thinking per second. Printing the bunny again at 540.

I went ahead and added an order of magnitude to all the values I had for jerk.

I'll update with the results.

Thanks.

-

Much better results, but I'm guessing I can go even further. Thanks for the tip.