I bought the Due3d 6HC a few years back, in good faith that the company supports CNC machines as advertised on the Homepage.

After many tries to somehow get to a point where i have a minimally viable Workflow, i can conclude that this product is not meant as a CNC Controller - never was and never will be. (While it still might be an very good 3D Printing board!)

The problems:

- There is an CNC Mode, but apart from a few UI tweaks, it does not do anything more than that.

- The main problem is: IT IS NOT REALTIME AT ALL!

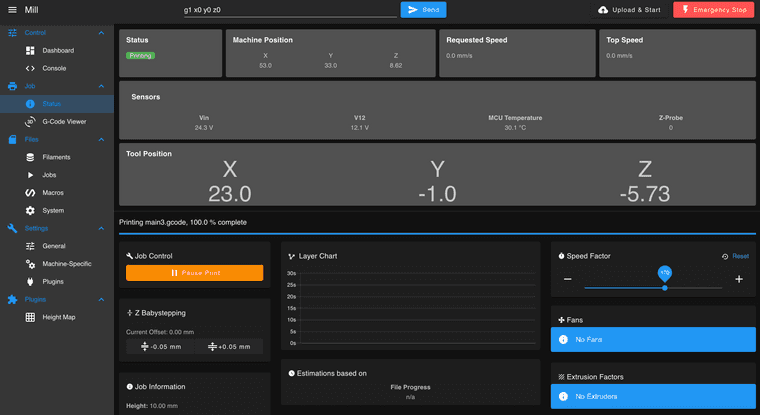

- You dont know where the tool is at any given point in time. The tool position shows some buffer value - it might be there at some point in the future..

- It can neither be stopped or change speed until the buffer is empty. In CNC Work, with often many long linear moves + circular moves, this might as well be at the end of the program.

- It does not understand, or worse misinterprets common commands like ARCS. There are a few topics in the forum about that.

- It fails at simplest commands when they are a bit differently formated. E.g. G1 Z-1.0000

- The Gcode Preview never worked, as it expects Extrusions!

Concluding: I know the RepRap-Firmware is a 3d printing firmware, but i assumed that the duet3d team did substantial changes to it, when writing CNC as use case on their homepage. They did not.

I just can assume that they, coming from electronics and 3d printing, have no idea what that even means.

PS: the reason i write this here - google will pick up on it, and maybe I will be able to warn a few people who read this from making the same mistake as me. If you need a proper 3-axis controller go with a UC400ETH and their software.