Duet3D is useless as a CNC Controller!

-

@dc42 @T3P3Tony

Thanks for the fast feedback! I guess i have to dig deeper into the parameters to make this controller useable for CNC.To my hostile first post - i just spend 3 hours failing at cutting a rectangle with rounded corners out of a piece of plywood - and gave up for today. I have hundreds of hours machine time and 15 years of experience - from semi-industrial machines to tiny GRBL controllers - and lets just say - the out of the box experience with duet3d is not ideal. The tone of my post reflects that.

As for the GCode - i went with the default-ish Mach3 postprocessor (using RhinoCam / VisualMill), and there the arcs got messed up (the two 'lower' ones - out of 4 total).

-

@Atair said in Duet3D is useless as a CNC Controller!:

s for the GCode - i went with the default-ish Mach3 postprocessor (using RhinoCam / VisualMill), and there the arcs got messed up (the two 'lower' ones - out of 4 total).

I think this may be the cause of the issues you are having. A Mach3 postprocessor will not produce g-code that works well with RepRap firmware.

-

and one additional suggestion - why no option to parse the code? check for soft limits etc. I can only upload it and then run it - any syntax or user errors show only when i am already cutting.. As the preview in my - 1-2 year old version - cant give me any indication of problems..

So even with an update to the latest firmware etc. - i think an option for a sanity check would be in order - which in turn would need a separate method besides run. 'Parse File' maybe?

-

@Atair there is the option to simulate a job.

-

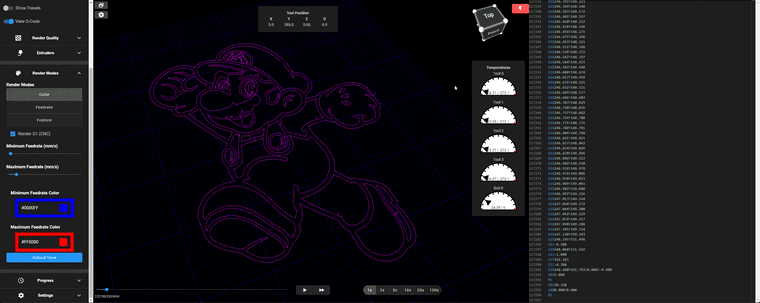

@T3P3Tony Thanks, found all i need after a firmware update (3.5.0 RC). The GCode viewer is a bit erratic, but it works.

What are good value ranges for the M669 Snnn Segments per second? I have it at 10 for now, it works, but still a little laggy. -

@Atair a value of 1 for S and T is fine

-

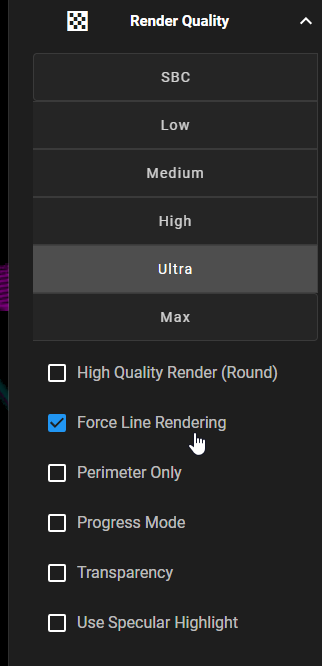

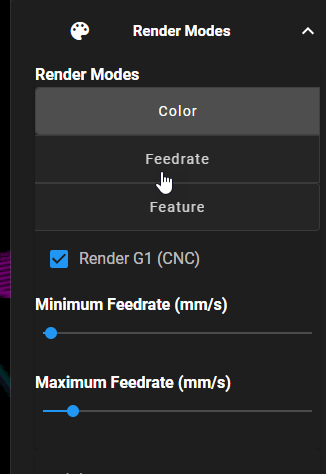

@Atair Sorry I am late to this, been a bit under the weather the past few days. When visualizing g-code for CNC Routers etc. I recommend setting the following settings.

Force line rendering (Make sure quality is not set to max)

Render G1 - Early on I ran into some cases where slicers were use G1 for everything including travels for 3d printers. I added this flag to help address G0/G1. Though I think with Fusion 360's changes they force all moves to G1 on their hobbyist versions so depending on what you use to generate g-code there could still be render issues.

With those settings you should have a better view of the toolpathing. Here is a sample of some drag knife tool pathing

-

@Atair said in Duet3D is useless as a CNC Controller!:

What are good value ranges for the M669 Snnn Segments per second? I have it at 10 for now, it works, but still a little laggy.

What is it that you find laggy: the response to a pause command, or something else?

At low speeds the T parameter (minimum segment length) matters too. In your example with S=10 and assuming the default T=0.2mm, if the speed is 2mm/sec or greater then the S parameter will define the segment time (0.1sec); but if the speed is lower than 2mm/sec then the T parameter will define the segment length. For example, at 1mm/sec the segments will be 0.2mm long and will take 0.2sec each. If you want to maintain 0.1sec response time to a pause command then you would need to reduce T to 0.1mm.

-

@dc42 i see, both parameters are relevant, my question was more in the direction of performance limits. (I am mostly interested in live feed rate adjustments)

Now with S10 it works, although i had two instances of gcode lines being interpreted wrong. I could not reproduce it, but both times it happend, the tooldhead was under load.

It was not lost steps, but the head moving to a totally wrong position.. Could be of course something different, but could also be data corruption.

Edit: and both times it was on the last segment of the gcode.. maybe there is something after all.. If i find out more i will post it. -

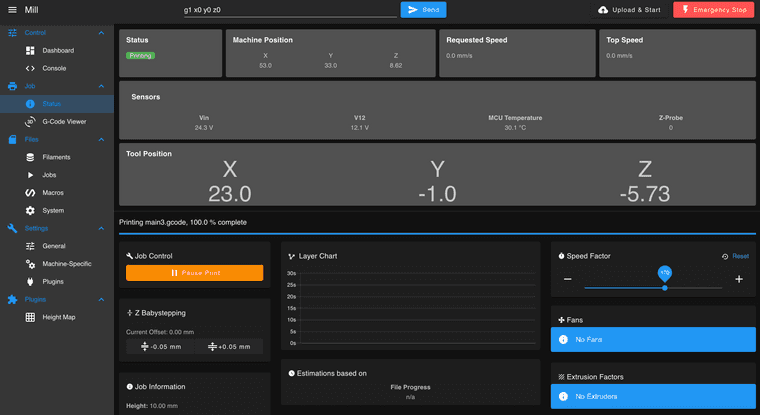

@dc42 ok i just ran another job.. and this time it did not fail, but also did not finish. main3.gcode

it just does not do the last line - a simple z axis move, and instead just stays there. i have to manually cancel it, and then reboot the controller.

I assume it is because of the S10? or some other thing with the current RC version?

using Duet Web Control 3.5.0-rc.1

thanks -

@dc42 ran the same code a second time, this time on the start of the last segment:

Line 423: G1 X263.075 Y-0.997 Z-7.000 F300.0

it never started this line, instead went diagonally towards zero i guess.. so happend 3x in a row - i was lucky that it is plywood and it did not break anything important, but there seems to be a real problem with this latest RC..

It never reached the last line, Line 424: G1 X263.075 Y-0.997 Z10.000 F1200.0, (the Z-Lift)I also have a second job, here: 4Holes.gcode It runs before the main cut, and never has any problems. I guess the lines are too short to have any effect with the segmentation.

Here my config.g in case that helps (there is also the M669 S10 command)

config.g