@T3P3Tony said in Mesh Bed Compensation Issue – Front Closer Than Rear:

Please can you confirm what you have done. Also post your heighmap.csv (or the heighmap file you are using if not the default)

Hi Tony,

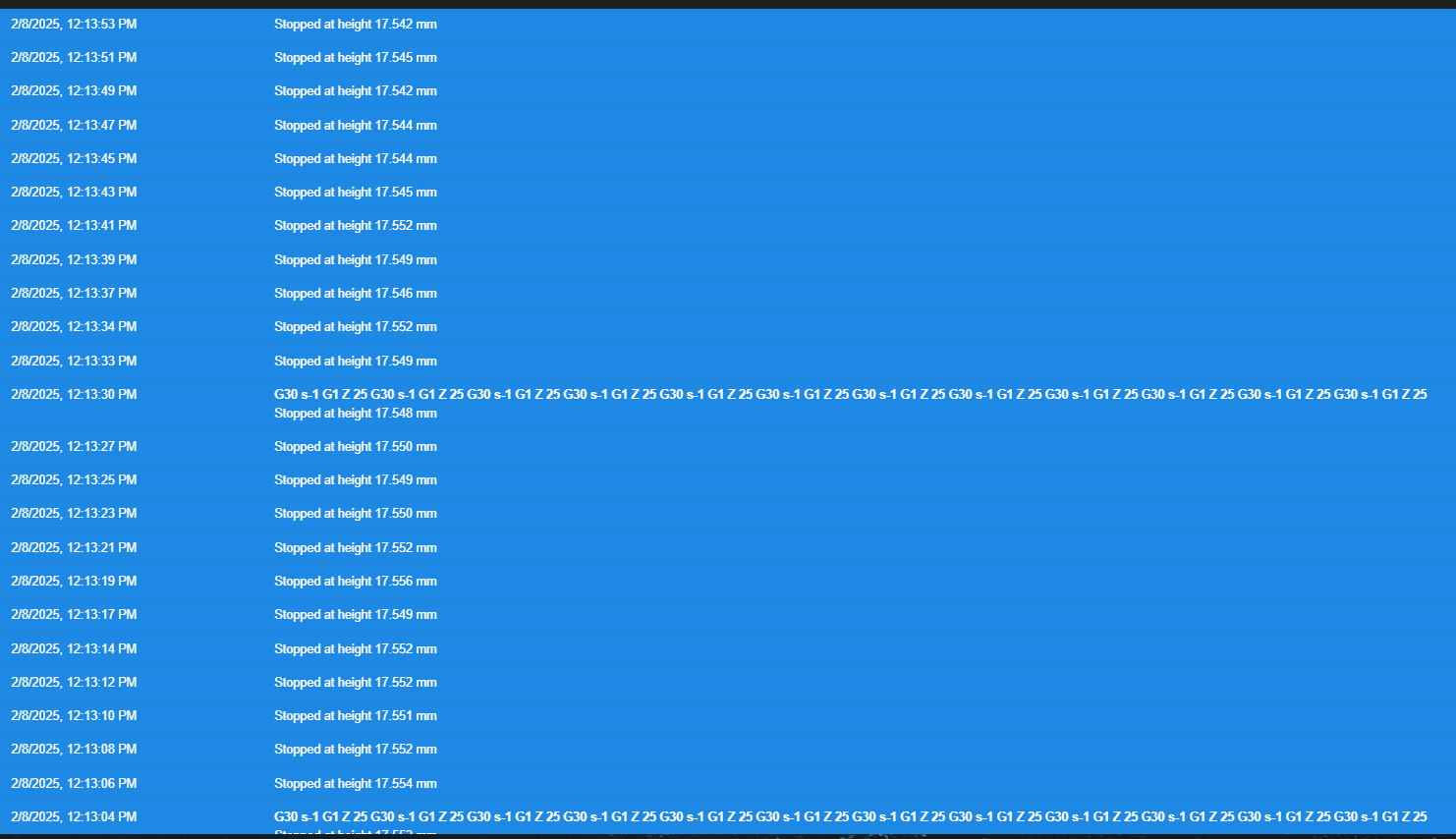

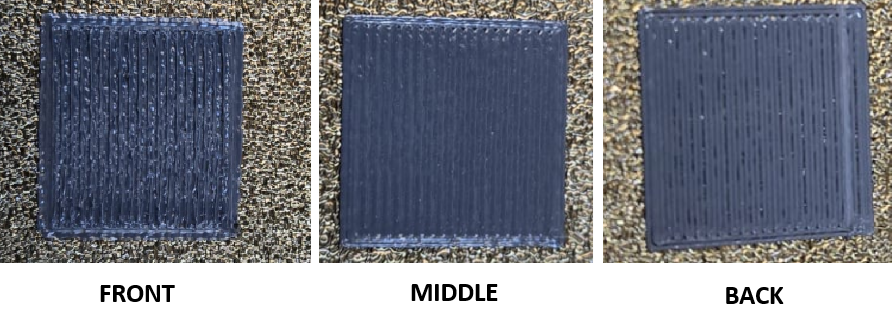

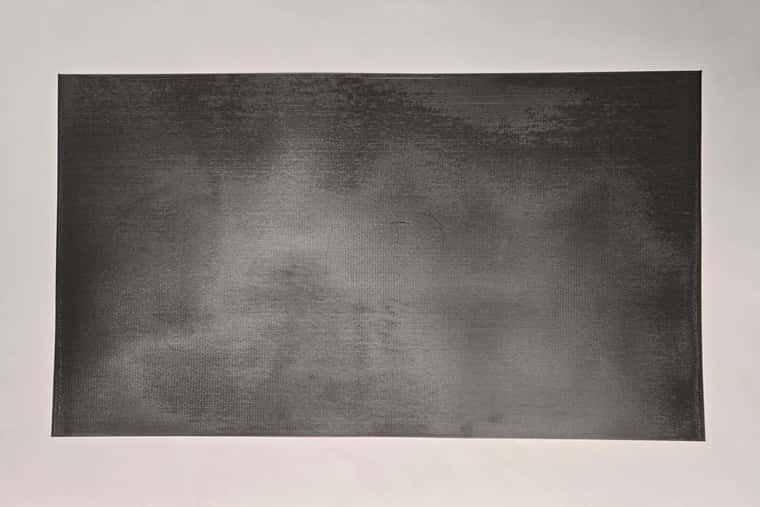

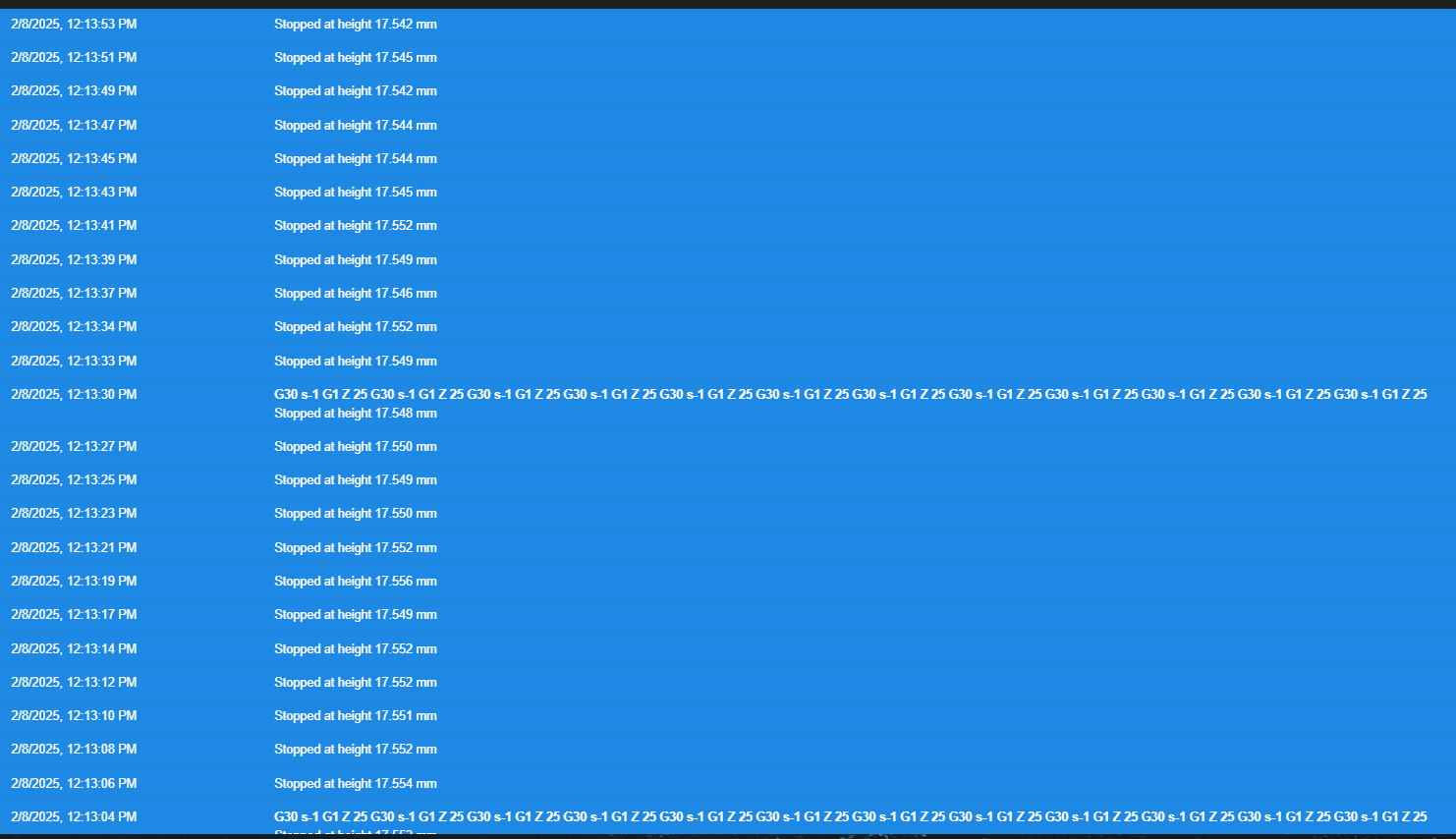

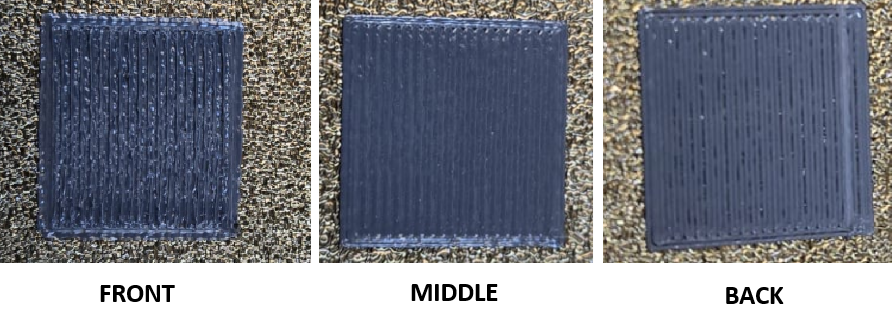

Thanks for your response! Below, I’m sharing my probe repeatability test results, the latest height map, homing files, and my updated config file.

I have tried to fine-tune the x y z axis steps per mm by measuring with a micrometer to ensure accuracy, did not work thus went back to stock steps per/mm. I have tested both three-point independent Z motor bed leveling and standard spring leveling, but the issue persists in both cases. Additionally, I have tried tweaking the lead screw coordinates to compensate for any potential mechanical misalignment. The mechanical system has been carefully checked for any loose components or inconsistencies. I have also tested after allowing the machine to thermally stabilize for 30+ minutes, but the results remain the same.

@droftarts said in Mesh Bed Compensation Issue – Front Closer Than Rear:

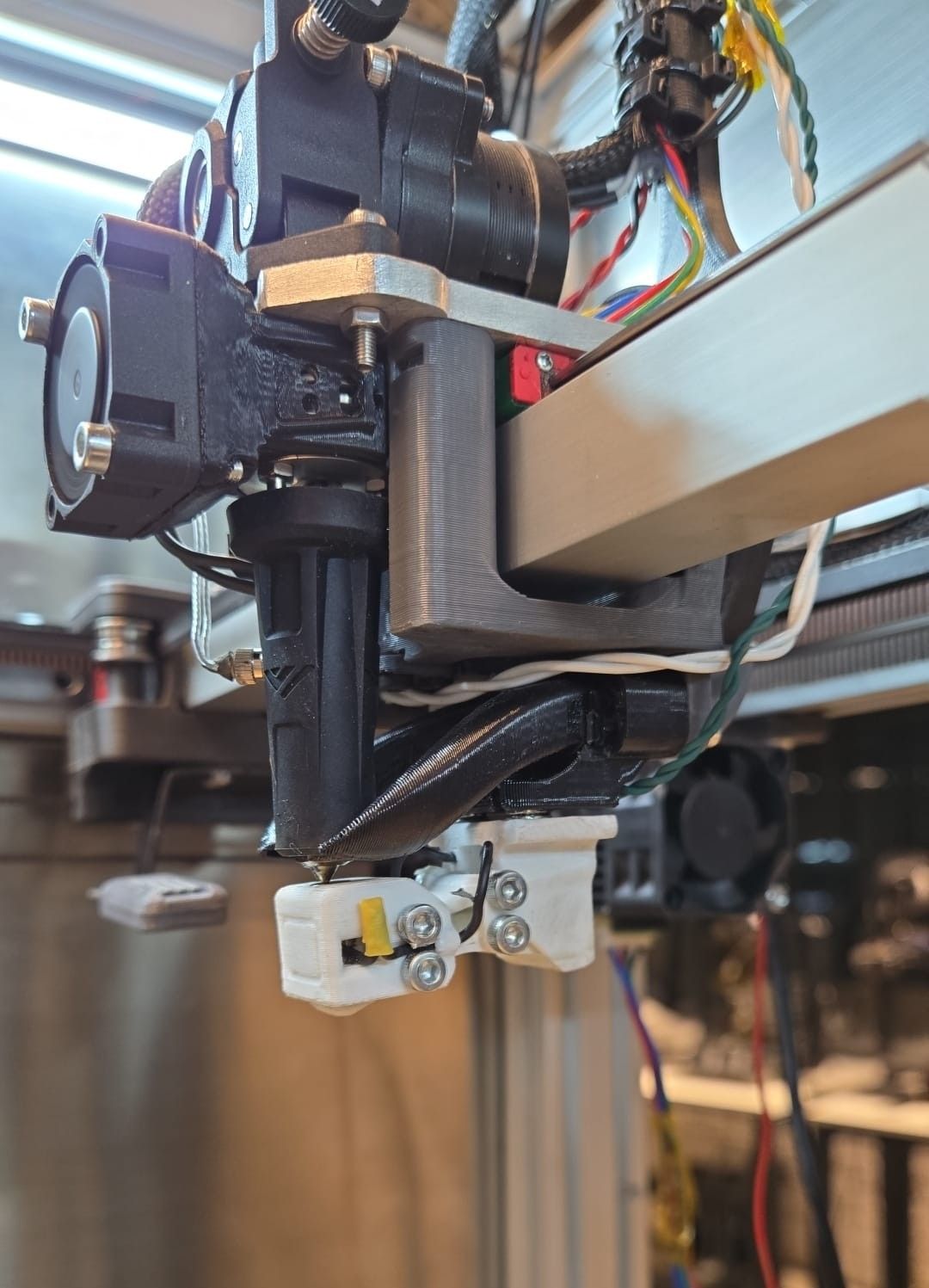

Please first check that your leadscrew couplings are tight, if that's how the motor is connected to the leadscrew, and that particularly the front Z carriage is moving freely on it's bearing, ie not getting stuck 'up'.

Do you use three-point bed levelling using the Klicky probe near the leadscrew positions before mesh levelling? Ideally you need to do this every time you turn the machine on, as the motors can jump a couple of full steps in either direction when powered up, so the bed will can be in a different position each time.

Not a big issue (though it depends what version of RRF you are using), but the following Gcodes in your config.g can only take one parameter for X, Y, Z and U (E can take as many parameters as there are extruders):

I have inspected the mechanical system, ensuring that the lead screw couplings are tight and that all Z carriages move freely without binding. I am using three-point independent Z motor leveling, the config has been adjusted according to your suggestion. However, after applying these updates, I am now getting the warning:

"Warning: the height map has a substantial Z offset."

Let me know if you need any additional details, and I appreciate any further suggestions!

M122

=== Diagnostics ===

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.5.4 (2024-11-24 10:43:42) running on Duet WiFi 1.02 or later + DueX5

Board ID: 0JD0M-9P6M2-NW4SJ-6J1F8-3SJ6M-1ASHK

Used output buffers: 17 of 26 (22 max)

=== RTOS ===

Static ram: 23488

Dynamic ram: 74988 of which 0 recycled

Never used RAM 12028, free system stack 98 words

Tasks: NETWORK(2,nWait 6,15.2%,222) HEAT(3,nWait 5,0.1%,328) Move(4,nWait 5,0.0%,274) DUEX(5,nWait 5,0.0%,18) MAIN(1,running,84.5%,742) IDLE(0,ready,0.2%,29), total 100.0%

Owned mutexes: WiFi(NETWORK)

=== Platform ===

Last reset 00:20:17 ago, cause: software

Last software reset at 2025-02-08 11:59, reason: User, Gcodes spinning, available RAM 15000, slot 0

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

Aux0 errors 0,0,0

MCU temperature: min 27.4, current 29.3, max 29.9

Supply voltage: min 23.9, current 24.1, max 24.4, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 99/0, heap memory allocated/used/recyclable 2048/520/520, gc cycles 0

Events: 0 queued, 0 completed

Driver 0: standstill, SG min 0

Driver 1: standstill, SG min 0

Driver 2: standstill, SG min 0

Driver 3: standstill, SG min n/a

Driver 4: standstill, SG min n/a

Driver 5: standstill, SG min 0

Driver 6: standstill, SG min 0

Driver 7: standstill, SG min 0

Driver 8: standstill, SG min 0

Driver 9: standstill, SG min n/a

Driver 10:

Driver 11:

Date/time: 2025-02-08 12:19:44

Cache data hit count 4294967295

Slowest loop: 195.87ms; fastest: 0.17ms

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 12.0MBytes/sec

SD card longest read time 8.1ms, write time 99.4ms, max retries 0

=== Move ===

DMs created 83, segments created 5, maxWait 137624ms, bed compensation in use: none, height map offset 0.000, max steps late 0, min interval 0, bad calcs 0, ebfmin 0.00, ebfmax 0.00

no step interrupt scheduled

Moves shaped first try 0, on retry 0, too short 0, wrong shape 0, maybepossible 0

=== DDARing 0 ===

Scheduled moves 238, completed 238, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 10], CDDA state -1

=== Heat ===

Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0

Heater 0 is on, I-accum = 0.2

=== GCodes ===

Movement locks held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

Daemon is idle in state(s) 0

Autopause is idle in state(s) 0

Q0 segments left 0

Code queue 0 is empty

=== DueX ===

Read count 39, 1.92 reads/min

=== Network ===

Slowest loop: 344.29ms; fastest: 0.00ms

Responder states: HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0)

HTTP sessions: 1 of 8

=== WiFi ===

Interface state: active

Module is connected to access point

Failed messages: pending 0, notrdy 0, noresp 0

Firmware version 2.2.0

MAC address e0:98:06:a4:41:ab

Module reset reason: Turned on by main processor, Vcc 3.42, flash size 4194304, free heap 31848

WiFi IP address 100.100.10.51

Signal strength -51dBm, channel 13, mode 802.11n, reconnections 0

Clock register 00002002

Socket states: 0 0 0 0 0 0 0 0

; Configuration file for Duet2 WiFi + DueX5 (firmware version 3.5.4)

; General preferences

G90

M83

M550 P"X Pro" ; set printer name

M575 P1 S1 B57600 ; configure PanelDue

;---------------------------------------------------------------------------------------------------------------------------------------------------------

; Network

M551 P"2845" ; set password

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; FTP

M586 P2 S0 ; Telnet

;----------------------------------------------------------------------------------------------------------------------------------------------------------

; Drives

M569 P0 S0 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes forwards

M569 P3 S0 ; physical drive 3 goes forwards

M569 P4 S0 ; physical drive 4 goes forwards

M569 P5 S1 ; physical drive 5 goes forwards

M569 P6 S1 ; physical drive 6 goes forwards

M569 P7 S1 ; physical drive 7 goes forwards

M569 P8 S1 ; physical drive 8 goes forwards

M584 X0 Y1:7 Z5:2:6 U8 E3:4 ; set drive mapping

M669 K0 X1:0:0:0 Y1:1:0:-1 Z0:0:1:0 U0:0:0:1

M671 X-115:245:615 Y-30:375:-30 S5 ; leadscrews at rear left, front middle and rear right

M350 X16 Y16 Z16 U16 E16:16 I1 ; configure microstepping with interpolation

M92 X80 Y80 Z800 U80 E691.84:691.84 ; set steps per mm

M566 X800.00 Y300.00 Z150.00 U800.00 E900.00:900.00 ; set maximum instantaneous speed changes (mm/min)

M203 X50000.00 Y30000.00 Z1600.00 U50000.00 E10000:10000 ; set maximum speeds (mm/min)

M201 X1000.00 Y750.00 Z500.00 U10000.00 E5000:5000 ; set accelerations (mm/s^2)

M906 X1800 Y1800 Z1250 U1800 E900:900 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S10 ; Set idle timeout

M911 S21.0 R23.0 P"M913 Z0 G91 M83 G1 X5 E-5 F1000"

M950 S8 C"duex.pwm2"

;-----------------------------------------------------------------------------------------------------------------------------------------------------------

; Axis Limits

M208 S1 X-64.4 Y-5 U0 Z-1 ; set axis minima

M208 S0 X500 Y315 U564.98 Z400 ; set axis maxima

;-----------------------------------------------------------------------------------------------------------------------------------------------------------

; Endstops

;Sağ ön Z ye bağlı e0stop, Sol ön e1stop, arka e2stop

M574 X1 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin ^xstop

M574 Y2 S1 P"ystop+duex.e3stop" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin ^ystop

M574 Z2 S1 P"e0stop+zstop+e1stop" ; configure active-high endstops for low end on Z via pins zstop and e1stop

M574 U2 S1 P"duex.e2stop" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin ^zstop

;----------------------------------------------------------------------------------------------------------------------------------------------------------------

; Z-Probe

M558 P8 R0.5 C"zprobe.in" H2 F400 T8000 A4 X0 Y0 Z5 ; set Z probe type to effector and the dive height + speeds

G31 P50 X0 Y3 Z17.55 ; set Z probe trigger value, offset and trigger height

M557 X30:470 Y30:270 S30 ; probe from X=20 to 530, Y=0 to 270mm with a mesh spacing of 30mm

;------------------------------------------------------------------------------------------------------------------------------------------------------------------------

; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 A"Bed_HEAT"

M950 H0 C"bedheat" T0

M307 H0 B0 R1.184 C132.5 D3.43 S1.00 V24.2

M140 H0

M143 H0 S120

M308 S1 P"e1temp" Y"pt1000" pt1000 B4138 A"X_HEAT"

M950 H1 C"e1heat" T1

M307 H1 R3.845 K0.473:0.000 D3.95 E1.35 S1.00 B0 V24.1

M143 H1 S301

M308 S2 P"e0temp" Y"pt1000" pt1000 B4138 A"U_HEAT"

M950 H2 C"e0heat" T2

M307 H2 R3.845 K0.473:0.000 D3.95 E1.35 S1.00 B0 V24.1

M143 H2 S301

;------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

; Fans

M950 F2 C"fan0" Q500

M106 P2 S1 H1 T40

M950 F3 C"fan1" Q500

M106 P3 S1 H2 T40

M950 F0 C"fan2" Q500

M106 P0 S0 H-1 C"X-PC"

M950 F1 C"duex.fan3" Q500

M106 P1 S0 H-1 C"U-PC"

M950 F4 C"duex.e4heat" Q500

M106 P4 S0 H-1 C"Chamber"

M950 F5 C"duex.e5heat" Q500

M106 P5 S0 H-1 C"Static"

M950 F6 C"duex.e6heat" Q500

M106 P6 S0 H-1 C"Under Bed"

;------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

; Tools

M563 P0 S"X" D0 H1 F0

G10 P0 X0 Y0 Z0 U0

G10 P0 R0 S0

M563 P1 S"U" D1 H2 F1 X3

G10 P1 Y0.4 U0 Z-0.05 S0 R0

G10 P1 R0 S0

; Create a tool that prints 2 copies of the object using both carriages

M563 P2 S"XU-Copy" D0:1 H1:2 X0:3 F0:1

G10 P2 X0 Y0 U-250 S0 R0

M567 P2 E1:1

M568 P2 S1

M563 P3 D0:1 H1:2 X0:3 F0:1 S"XU-Mirror"

G10 P3 X0 Y0 U-500 S0 R0

M567 P3 E1:1

M568 P3 S1

; bed.g

; called to perform automatic bed compensation via G32

G90

G29 S2

M561

T0

G28

G1 X372 F6000 ; Go to Klick pick up point

M280 P8 S20 ; Opes servo arm

G4 P1000

M280 P8 S20 ; Opes servo arm

G1 Y260 F5000 ; Pick Up Klick

M280 P8 S130 ; Close servo arm

M400

G1 X250 Y150 Z120 F5500 ; Go to bed center

G30 ; Probe onece for Z=0

G30 P0 X250 Y270 Z-99999 ; probe near a leadscrew

G30 P1 X8 Y0 Z-99999 ; probe near a leadscrew

G30 P2 X483 Y0 Z-99999 S3 ; probe near a leadscrew and calibrate 3 motors

G30 P0 X250 Y270 Z-99999 ; probe near a leadscrew

G30 P1 X8 Y0 Z-99999 ; probe near a leadscrew

G30 P2 X483 Y0 Z-99999 S3 ; probe near a leadscrew and calibrate 3 motors

G1 X250 Y150 F6000 ; Go to bed center

G30 ; Probe onece for Z=0

G29

G1 Z120 F5000 ; Lower Bed

G1 X372 Y260 F5000 ; Go to Klick pick up point

M280 P8 S22 ; Opes servo arm

G1 X372 Y312 F2000 ; Drop Klick

G1 X322 Y312 F2000 ; Remove Klick

M280 P8 S130 ; Close servo arm

M400

; homez.g

; called to home the Z axis

M400

M400 G91

G1 H1 Z800 F15000

G1 H2 Z-5 F7500

G1 H1 Z500 F4500

G90

M400

;homeall.g

; called to home all axes

;---------------------------------------------------------------------------------------------------

M400

M400 G91

G1 H1 X-505 F4000

G1 H2 X5 F9500

G1 H1 X-320.5 F4000

G90

M400

;---------------------------------------------------------------------------------------------------

M400

G91

G1 H1 U505 F4000

G1 H2 U-5 F9500

G1 H1 U30 F4000

G90

M400

;---------------------------------------------------------------------------------------------------

G1 X-40 U547

;---------------------------------------------------------------------------------------------------

M400

G91

G1 H1 Y305 F4000

G1 H2 Y-5 F8000

G1 H1 Y305 F3500

G90

M400

;---------------------------------------------------------------------------------------------------

G1 Y305

;---------------------------------------------------------------------------------------------------

M400

G91

G1 H1 X-505 F4000

G1 H2 X5 F9500

G1 H1 X-320.5 F4000

G90

M400

;---------------------------------------------------------------------------------------------------

M400

G91

G4 P200

G1 H1 U505 F4000

G1 H2 U-5 F9500

G1 H1 U30 F4000

G90

M400

;---------------------------------------------------------------------------------------------------

M400

M400 G91

G1 H1 Z800 F15000

G1 H2 Z-5 F7500

G1 H1 Z500 F4500

G90

M400

RepRapFirmware height map file v2 generated at 2025-02-07 21:50 min error -0.098 max error 0.176 mean 0.056 deviation 0.055

axis0 axis1 min0 max0 min1 max1 radius spacing0 spacing1 num0 num1

X Y 2.75 497.67 1.83 295.96 -1 32 32 16 10

0.022 0.017 0.051 0.052 0.046 0.066 0.128 0.091 0.171 0.124 0.106 0.107 0.134 0.121 0.114 0.078

0.005 0.027 0.087 0.056 0.081 0.072 0.119 0.134 0.13 0.119 0.069 0.11 0.084 0.076 0.077 0.064

-0.011 0.012 0.041 0.055 0.066 0.084 0.136 0.124 0.138 0.109 0.098 0.143 0.098 0.109 0.076 0.068

0.004 0.022 0.055 0.082 0.059 0.079 0.132 0.107 0.176 0.083 0.103 0.106 0.099 0.07 0.049 0.005

-0.029 -0.001 0.021 0.036 0.092 0.044 0.093 0.124 0.126 0.088 0.075 0.057 0.07 0.068 0.007 -0.081

-0.068 -0.028 -0.001 0.031 0.055 0.052 0.062 0.068 0.097 0.08 0.064 0.039 0.051 0.036 0.017 -0.066

-0.071 -0.026 -0.018 0.007 0.007 0.008 0.077 0.112 0.114 0.063 0.03 0.015 0.058 0.046 0.014 -0.041

-0.068 0.049 0.117 0.047 -0.005 0 0.086 0.105 0.129 0.089 0.051 0.012 0.048 0.049 0.046 -0.036

-0.098 -0.033 -0.01 -0.028 0.022 -0.001 0.052 0.101 0.112 0.077 0.077 0.108 0.026 0.037 0.054 -0.022

-0.053 -0.055 -0.041 -0.015 0.001 0.023 0.069 0.111 0.126 0.094 0.119 0.095 0.116 0.092 0.116 0.041