Does anyone have some in site on this?

Latest posts made by Wallabear

-

RE: IDEX Config help and Tuningposted in Tuning and tweaking

-

RE: IDEX Config help and Tuningposted in Tuning and tweaking

@dc42 Thanks for that I am going to start with 0,0 centered for now. On a different but same note I had a few quick questions you might be able to help me with. I have been going through the documentation on setting up “bed leveling using multiple independent z motors”. Everything seems straight forward at first, however factoring in that my printer is also a IDEX as well add a layer of complexity that is causing me some confusion. When I set up the IDEX I moved one of the extruders to drive #5 on my duex5 and put the U axis onto drive #3 as in the example for “configuring multiple independent X-carriages on a cartesian printer”. In that section I had to set values for the U axis in the M574, M906, M201, M203, M566, M208, and M92. To start my list of questions; 1) in the documentation for setting up the multiple z axis it has the second z axis assigning to drive #4, does this mean that I need to move the extruder that I have assigned to that drive to drive #6 on the duex5 and re assign it in the RRF or can I just assign the second Z motor to drive#6? I did see the very important note on the M584 at the bottom, but was unclear if the drives on the duex boards defaults to being an extruder drive. 2)I saw in the Example config.g file M584 had z assigned to “Z2:4” but no axis set up such as V (in my case) for the configuration of steps, speeds, accel. . .etc. Does that mean that in this case drive 2 and 4 are both pulling form the same commands to set these values or do I need to define a V axis as well? 2.5) do I need to map the drive for the new Z axis using the M569 command? 3) on the M671 commands what is the S0.5 modifier at the end of it? 4) would taking more than 2 points across the bed say; left, center, and right generate a better line to level the gantry or are just 2 points (left and right) to get a good line to level to 5) and I am assuming that the S2 modifier on the G30 command in the bed.g file is what tells the printer to calibrate the 2 motors based on the points it has taken.

I do want to say that the documentation and examples are top notch and have helped me out significantly in setting up this machine and getting used to RRF. Thank you for all of those examples and work you guys have put into the documentation!!!

-

RE: IDEX Config help and Tuningposted in Tuning and tweaking

@bricor My machine is similar to a CR-10 or a Prusa where the z axis has to drive motors. I read on the forum that you can put each motor on their own drive and also run a gantry level I believe that the Gcode is G32. I am working on setting up Cura right now.

-

RE: IDEX Config help and Tuningposted in Tuning and tweaking

@bricor yes I found the literature very through too. It helped me out a lot. There are still some points that I am not fully clear on but have been doing more reading.

Do you need to do anything special for tool changes? I saw thal my tpre.g files seem to be empty is there something I need to put in there? I tend to use a mix of Cura, PrusaSlicer2.0 and Simplify3d depending on what I am printing. I am hoping to get my extruders calibrated today and start printing some calibration prints. Have you messed with seperate Z axies running IDEX? That is the next thing I need to concur after I get this thing laying some plastic

-

RE: IDEX Config help and Tuningposted in Tuning and tweaking

@bricor so if I read your coordinates correctly your 0,0 is set to a bed corner. In an IDEX system is it preferable for bed zero at a corner or center. In most of my other machines they center at a corner, but I did set this one up to zero at the center. With the RRF changing this would be quite simple (one of the reasons I am falling in love with this environment). This is the first IDEX machine I have ever built or operated. Though I have read a lot of the articles getting advice from people who have experience with this set up is helpful. A BIG thank you! One more ? What slicer are you using?

-

RE: IDEX Config help and Tuningposted in Tuning and tweaking

After doing some more reading I think I figured out my first question about the movement. I have to adjust my M208 to have a -integer thus pushing the edge of my bed where it should be e.g.

M208 X-321.5:155 Y-165:155 U-155:321.5or

M208 S-321.5 X-165 Y-10 U-155 M208 S1 X155 Y155 U321.5If I am not mistaken that should center the bed. The only portion I am a little fuzzy on is the U axis? can anyone confirm or deny my though process on this please

-

RE: Caution! - STL Resolutionposted in General Discussion

I was also having issues with stl files. Firstley when I exported them from Solidworks I always maxed out the resolution which made for some pretty big file sizes, but really helped with the print rez. That is also the second was the file sizes were getting crazy big. I am now exporting my diles in .3mf format and I could not be happier. The file sizes are manageable and the print resolution for me is just as good if not better. If you have not trued out a .3mf file I would suggest you do. I sliced the same part in both formats and same print settings and the .3mf format still printed a better quality than the STL

-

RE: IDEX U Axis not reporting location in web control?posted in Duet Web Control

@dc42 thanks you for the help I will give it a try. I do not have a previous version of DWC1 on my sd card at the moment when I get a chance later I will download a version of it and put it on there.

-

IDEX Config help and Tuningposted in Tuning and tweaking

Duet 2 wifi

Duex5

Firmware: 2.04RC3Ok, I am VERY new to the RRF environment, but not new to printing, I have been running for 5 years or so in the Marlin environment and built many printer under that environment; I have moved to the Duet and RRF for setting up this printer. I am setting up an IDEX machine that I have been working on for the last couple of months, a little here and there. I have finally gotten all of the mechanics working, everything is testing fine. All the axis home correctly, The BL Touch is working fine, the nozzles heat up, the bed heats up and at least the always on fans are working correctly, but have not tested the part cooling fans as they are going to be set up to run based on layers not temp. I have been doing a lot of reading here on the forum from other people on issues they have had with their IDEX set up and it has help me greatly get to the point I am at right now. I am having a couple issues of my own, such as tool changing. I am not clear on how exactly to handle the movement and make sure the heads park correctly. More specifically in the example below, shown in the sample code on the duet page, why is the T0 parked at X-48? When the tool homes should not the X position be X0 (or X1 so that you could fast travel to the position), especially if the movement is set in absolute movement? In this example is the X/U/Y 0,0,0 been reset to the center of the bed or even the edge? On that note is setting the bed center to X/U/Y 0,0,0 recommended?

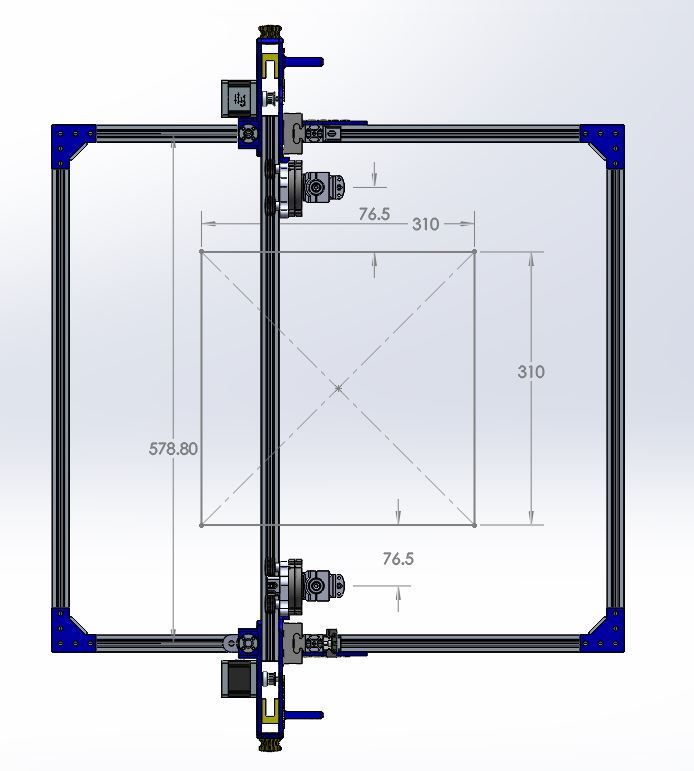

M83 ;relative extruder movement G1 E-12 F3600 ;retract 2mm M106 S0 ;turn off print cooling fan G91 ;relative axis movement G1 Z33 F500 ;Z up 3mm G90 ;absolute axis movement G1 S2 X-48 F6000 ;Park the X carriage at -48mmI have attached all of my config files, could someone with a little more experience be kind enough to take a look at these files and tell me where I am wrong with the set up, and what needs done to fix it that way I know. I have also included a dimensional top view of my printer to aid in the inspection of the config files. It is essentially a CR-10 style printer that I have widened the frame on to accommodate moving the X/U carriages out of the way and allowing the active tool to have complete travel of the bed. I still have to get the tool offsets figured out but I think I can follow the example in the setup and get close.

I am also contemplating separating out the Z

axis onto their own driver so that I can level the gantry as well; I have been reading about that too and it seems like a good idea. Since I already have a U axis set up for the second X carriage would I move the one Z motor to P5 on the Duet2 wifi and then move E0/E1 to P6/P7 on the Duex5? Or would I just move the one z motor to P7 on the Duex5? I am not clear if there is an order that must be maintained in this situation. If whomever is kind enough to help; you can either PM me or E-mail: Wallabear@gmail.com if you so choose. Replying directly works too

tpre1.g tpre0.g tpost1.g tpost0.g tfree1.g tfree0.g stop.g sleep.g retractprobe.g resume.g pause.g homez.g homey.g homex.g homeu.g homeall.g deployprobe.g config.g bed.g

tpre1.g tpre0.g tpost1.g tpost0.g tfree1.g tfree0.g stop.g sleep.g retractprobe.g resume.g pause.g homez.g homey.g homex.g homeu.g homeall.g deployprobe.g config.g bed.g -

RE: New RepRapFirmware config toolposted in General Discussion

Will there be an updated config tool for the Duet 3? If yes will it also work with the Duet 2 as well? With the added flexibility of the Duet 3 it would be really nice if the config too would be able to configure advanced options like adding an axis or two or 5. Not that going into the .g files and configuring the special setups is hard or anything but it would be really nice if a config tool existed for advanced options to handle most of the set up and then jumping into the .g files for final tweaking.