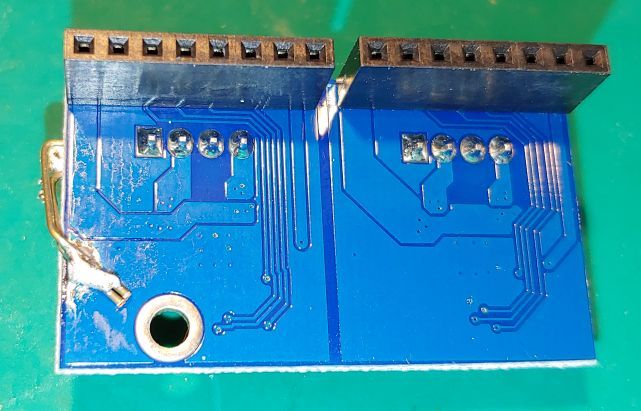

Looking at the layout render, it looks like the culprit is the Vin trace to C6. It cuts off the direct path to ground and forces current from R3 to loop around the outside of the pcb. Personally, I'd put R3 and R2 between the TMC chip and stepper connector and give them 2-4 vias to the ground plane and the thermal die pad of the TMC. The motor phase connections can then sneak under or around the 805 resistor.