I also tried setting the G10 offset in between prints using the same Gcode, and I see no Y-offset being applied at all. When I apply the offset and move the printhead to the same position (for example X100 Y100) I do see the difference in Y, yet in the print itself it doesn't seem to work.

Best posts made by Madtraxx

-

RE: Y-offset not being appliedposted in Tuning and tweaking

Latest posts made by Madtraxx

-

RE: Y-offset not being appliedposted in Tuning and tweaking

I am using RRF 3.2.2.

I got a -sorta- fix. Apparently the offset of the second nozzle isn't applied, yet when I apply it to the first nozzle it seems to work. Maybe this would need more investigation why the y-offset is only applied on the first nozzle and not the second. -

RE: Y-offset not being appliedposted in Tuning and tweaking

I also tried setting the G10 offset in between prints using the same Gcode, and I see no Y-offset being applied at all. When I apply the offset and move the printhead to the same position (for example X100 Y100) I do see the difference in Y, yet in the print itself it doesn't seem to work.

-

RE: Y-offset not being appliedposted in Tuning and tweaking

And some pictures for reference that I am very happy with my results thus far! (except the tiny Y-offset)

And a video (to see the tool change working)

VID_20210304_112944_01_432x768.mp4 -

Y-offset not being appliedposted in Tuning and tweaking

Hi all,

With previous posts getting my UltiDuet (Ultimaker 2 + Duet + Dual nozzle) to work I am now in the final steps of calibration. I seem to have the X and Z offset of my second nozzle calibrated, yet the Y-offset seemns a little off still. In my slicer I have just the same filse sliced and I do tweaks on my config.g file to set the offsets.The weird thing is that no matter how much I change the Y-offset my print doesnt seem to line up perfectly, yet the tool change macro I use (to change the nozzle) no longer lines up to its too change position, so some form of offset is being applied, yet not on the print itself.

This is my config.g:

; Configuration file for Duet Ethernet ; executed by the firmware on start-up ; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M575 P1 B57600 S1 ; Network M550 PUltiDuet ; Set machine name M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; Drive 0 goes backwards M569 P1 S0 ; Drive 1 goes forwards M569 P2 S0 ; Drive 2 goes backwards M569 P3 S0 ; Drive 3 goes forwards M569 P4 S0 ; Drive 4 goes forwards M584 X0 Y1 Z2 E3:4 M350 E256:256 I0 ; Disable interpolation on extruder M350 X16 Y16 Z16 I1 ; Configure microstepping with interpolation M92 X80 Y80 Z400 E6500:6500 ; Set steps per mm M566 X900 Y900 Z12 E500 ; Set maximum instantaneous speed changes (mm/min) M203 X18000 Y18000 Z2400 E2700 ; Set maximum speeds (mm/min) M201 X3000 Y3000 Z500 E1500 ; Set accelerations (mm/s^2) M906 X1200 Y1200 Z1200 E1000 I30 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; Set axis minima M208 X220 Y220 Z213 S0 ; Set axis maxima ; Endstops M574 X1 S1 P"!xstop" M574 Y2 S1 P"!ystop" M574 Z2 S1 P"!zstop" ; Z-Probe M558 P0 H5 F120 T6000 ; Disable Z probe but set dive height, probe speed and travel speed M557 X15:215 Y15:210 S20 ; Define mesh grid ;Heaters version 3 M308 S0 P"spi.cs2" Y"rtd-max31865" M308 S1 P"spi.cs1" Y"rtd-max31865" M308 S2 P"spi.cs3" Y"rtd-max31865" M950 H0 C"bed_heat" T0 M950 H1 C"e0_heat" T1 M950 H2 C"e1_heat" T2 M140 H0 M307 H0 B0 S0.80 ; Disable bang-bang mode for the bed heater and set PWM limit ; Fans M950 F0 C"fan0" Q500 M950 F1 C"fan1" Q500 M950 F2 C"fan2" M106 P0 S0 I0 H-1 ; Set fan 0 - print cooling side fans M106 P1 S255 I0 H1:2 T35 ; Set fan 1 - heatsinkfan -value, M106 P2 S160 I0 H-1 ; Set lights ; Tools M563 P0 D0 H1 ; Define tool 0 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C M563 P1 D1 H2 ; Define tool 1 G10 P1 X19.1 Y-1.5 Z-1.25 ; Set tool 0 axis offsets G10 P1 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ;M572 D0 S0.6 ; Set Pressure advance ; Automatic saving after power loss is not enabled ; Custom settings are not configured M501 ; Set the active parameters to those stored in sys/config-override.g on the SD cardFor tool 0 I dont have any offset, and just for Tool 1 the actual nozzle position changes:

tfree1.g: Sadly I couldnt retrieve the offsets here to calculate in, so I had to calculate it manually; called when tool 1 is freed ; ; To make sure the printhead doesnt crash into the dock if {move.axes[0].machinePosition > 197.0} G90 G0 F8000 X196 G90 if state.currentTool == 1 G0 F8000 X215.1 Y182.35 G0 X223.1 Y182.35 G0 X223.1 Y202.35 G0 X215.1 Y202.35 G10 P1 X19.1 Y-0.65 Z-1.25 else G0 F8000 X196 Y183 G0 X204 Y183 G0 X204 Y203 G0 X196 Y203tpre1.g:

if {move.axes[2].machinePosition < 2} G91 G0 Z2 M98 P"/macros/Nozzle_2_Enable" G91 G0 Z-2 else M98 P"/macros/Nozzle_2_Enable"where Nozzle_2_Enable:

if {move.axes[2].machinePosition < 5} G91 G0 Z5 if {move.axes[0].machinePosition > 197.0} G90 G0 F8000 X196 G90 G0 F8000 X196 Y220 G0 X206 Y220 G0 X206 Y201 G0 X196 Y201 G91 G0 Z-5 else G91 if {move.axes[0].machinePosition > 197.0} G90 G0 F8000 X196 G90 G0 F8000 X196 Y220 G0 X206 Y220 G0 X206 Y201 G0 X196 Y201 -

RE: Conditional commands in macroposted in Gcode meta commands

Flashing the correct firmware this time (>3.3.1) has resolved the issue. Thanks for all the information!

-

RE: Conditional commands in macroposted in Gcode meta commands

I changed to DFF v3 and changed the needed config lines to make my printer operational again.

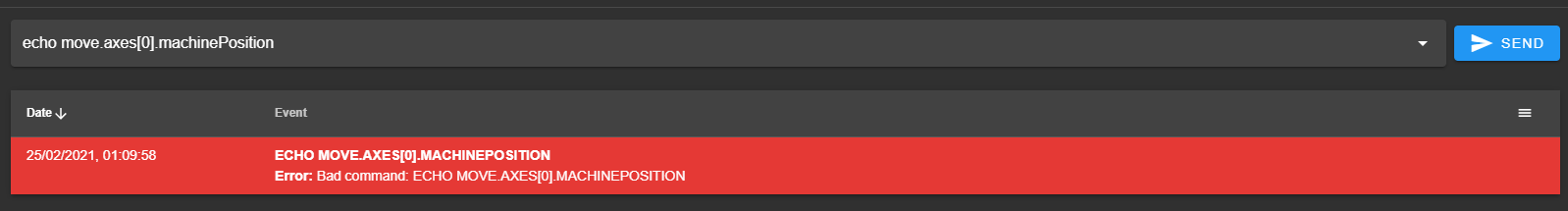

Running "echo move.axes[0].machinePosition" in the console I still get the following:

Also changing the macro to the code that @T3P3Tony mentioned also didn't seem to work.

-

RE: Conditional commands in macroposted in Gcode meta commands

Currently I am using RepRapFirmware for Duet 2 WiFi/Ethernet 2.03 (2019-06-13b2). Beginner's mistake here i guess to assume I used 3.2.2 (but it was only the Duet WEb Control 3.2.2)...

@T3P3Tony sending that command trhough the console gives me back the same "Bad command" message.

-

RE: Conditional commands in macroposted in Gcode meta commands

I tried, yet I still get the error and lines 2 and 3 are executed even when X<195

-

Conditional commands in macroposted in Gcode meta commands

Hi all,

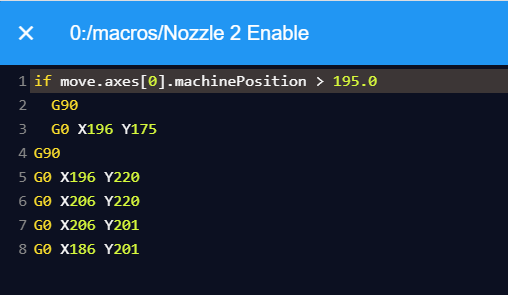

I'm trying to get a conditional move command into a tool change macro, as with X being over 195 it will crash the lever into the actual tool change tab (ultimaker 3 style).For this I have the following command, yet whatever I try I cannot seems to get it right (as I keep getting a "Bad command" message

-

RE: Dual hotend cooling fanposted in Duet Hardware and wiring

Thank you! That seemed to do the trick.