Hello Guys

I'm stuck with an issue and can't figure out why. I've configured my toolchanger with four tools (T0 - T3) and mapped the thermistors and heaters to the tools with M308 and M563. The Drivers should be assigned as well with M584 X5 Y6 Z7:8:9 C2 E4:3:0:1 ; Assign motors to axes. The M584 comes before M308 and M563.

The issue:

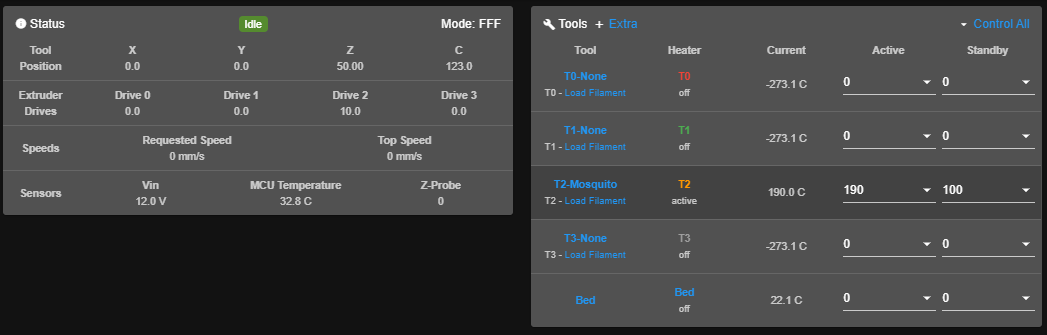

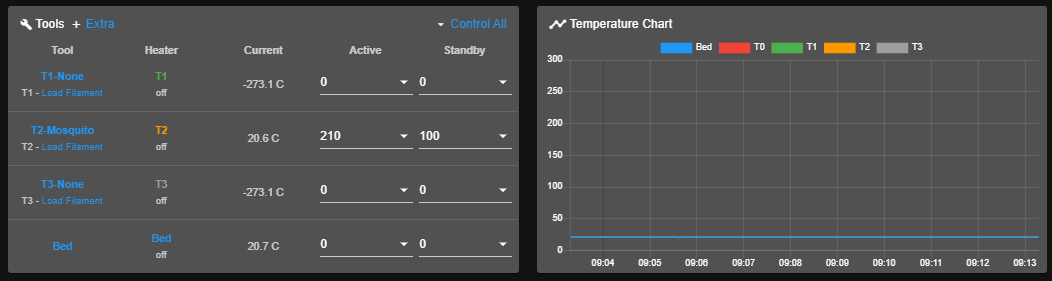

I can select the Tool 2 in DWC and the Toolchanging sequence begins. I can check with ''T'' and get the status ''Tool 2 is selected''. Now I can heat up the hotend and than I hit ''Extrude'' in the Dashboard section of DWC. I instantly get the error message ''...no Driver 4 connected'' and that's correct because Tool 0 has no stepper connected yet but I've selected Tool 2 with the Driver 0 which has a stepper connected.

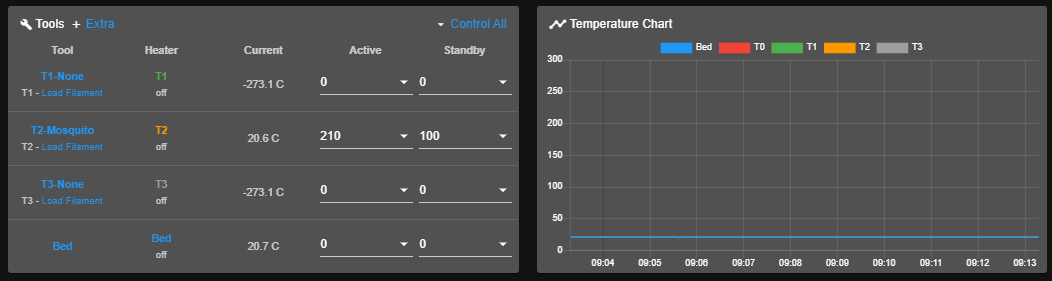

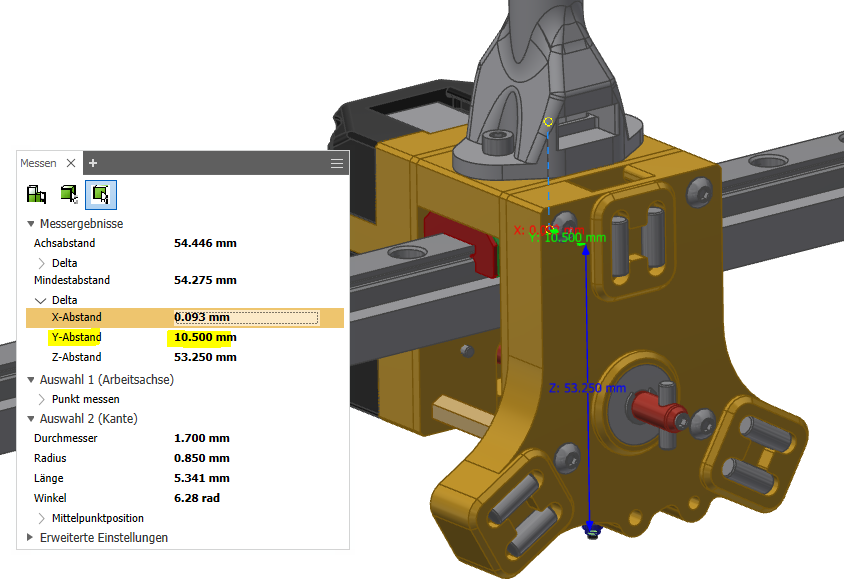

What's strange as well I can't see the Tool 0 in DWC (left side of the picture):

Thank you for your help.

My Config.g file:

; General preferences-------------------------------------------------------------------------------------------------------------

M111 S0 ; Debugging off

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M555 P2 ; Set firmware compatibility to look like Marlin

M575 P1 B57600 S1 ;Set baud rate Duet Board.

M575 P0 B57600 S1 ;Set baud rate USB

; Network------------------------------------------------------------------------------------------------------------------------------

M550 P"CHANGER" ; Set machine name

M552 S1 ; Enable Networking

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet

; Printer Type-------------------------------------------------------------------------------------------------------------------------

M667 S1 ; Select CoreXY mode

; Steppers/Drives--------------------------------------------------------------------------------------------------------------------

M584 X5 Y6 Z7:8:9 C2 E4:3:0:1 ; Assign motors to axes

M569 P0 S1 ; Drive 0 goes forwards Extruder 2 (Tooldock D2)

M569 P1 S1 ; Drive 1 goes forwards Extruder 3 (Tooldock D3)

M569 P2 S0 ; Drive 2 goes backwards Coupler-Motor

M569 P3 S1 ; Drive 3 goes forwards Extruder 2 (Tooldock D1)

M569 P4 S1 ; Drive 4 goes forwards Extruder 1 (Tooldock D0)

M569 P5 S0 ; Drive 5 goes backwards Y-Stepper

M569 P6 S0 ; Drive 6 goes backwards X-Stepper

M569 P7 S0 ; Drive 7 goes backwards Z1 motor left

M569 P8 S0 ; Drive 8 goes backwards Z2 motor rear

M569 P9 S0 ; Drive 9 goes backwards Z3 motor right

M671 X200:0:-200 Y125:-200:125 S4 ; Lead screw positions , Snn Maximum correction allowed for each leadscrew in mm (optional, default 1.0)

; Endstops -----------------------------------------------------------------------------------------------------------------------------

M574 X1 S1 P"xstop" ; Set X endstop (switch)

M574 Y2 S1 P"ystop" ; Set Y endstop (switch)

M574 Z0 P"nil" ; No Z endstop @used by DC42 using G30 homing

M558 P8 C"zstop" H5 F120 T10000 A5 S0.01 ; Set Z probe type to switch

G31 Z0 ; Set Z probe trigger value, offset and trigger height

M557 X-145:145 Y-120:98 S30 ; Set Z probe: Define mesh grid

M574 C1 S3 ; Stall detect coupler at low end of its range

; Stepper driver ---------------------------------------------------------------------------------------------------------------------

M350 E16:16:16:16 I1 ; Configure E microstepping with interpolation

M350 C8 I0 ; Configure C microstepping with interpolation

M350 X16 Y16 Z16 I1 S2 ; Configure XYZ microstepping with interpolation

M92 X80.3 Y80.3 Z1596 C100 E834:834:409:834 ; Set steps per mm

M906 X1100 Y1100 Z1000 C400 E900:900:900:900 I30 ; Set motor currents (mA)

M84 S120 ; Set idle timeout

; Stall Detection

M915 C S3 F1 H400 R0 ; Coupler

M915 X Y S3 F0 H400 R0 ; X / Y Axes

; Axis ------------------------------------------------------------------------------------------------------------------------------------

M208 X-180.2:180.2 Y-125:139.65 Z0:280 C0:240 S0 ; Set axis maxima & minima

M566 X300 Y300 Z20 C2 E100 150:100 ; Set maximum instantaneous speed changes

150:100 ; Set maximum instantaneous speed changes

M203 X15000 Y15000 Z1200 C5000 E5000:5000:5000:5000 ; Set maximum speeds (mm/min)

M201 X2500 Y2000 Z500 C500 E2500:2500:2500:2500 ; Set accelerations (mm/s^2)

; AAR ---------------------------------------------------------------------------------------------------------

M593 F50 ; cancel ringing at 50Hz

M376 H0 ; bed compensation taper, Ausschleichhöhe

; Bed and Tools

; >Heaters< ---------------------------------------------------------------------------------------------------------------------------

; Heatbed

M308 S0 P"bedtemp" Y"thermistor" A"Bed" T100000 B4138 C0 ; Set thermistor

M950 H0 C"bedheat" T0 ; Bed heater

M140 H0 ; Add heater to bed after RRF3.01 RC10

M143 H0 S120 ; Set temperature limit for heater 0 to 225C

; Tooldock D0

M308 S1 P"e2temp" Y"thermistor" A"T0" T100000 B4138 C0 ; Set thermistor

M950 H1 C"!exp.heater3" T1 ; Heater on E2 Heater

M143 H1 S300 ; Set temperature limit for heater 1 to 300C

; Tooldock D1

M308 S2 P"e3temp" Y"thermistor" A"T1" T100000 B4138 C0 ; Set thermistor

M950 H2 C"!exp.heater4" T2 ; Heater on E3 Heater

M143 H2 S300 ; Set temperature limit for heater 2 to 300C

; Tooldock D2

M308 S3 P"e4temp" Y"thermistor" A"T2" T100000 B4138 C0 ; Set thermistor (Thermistor on E4)

M950 H3 C"!exp.heater5" T3 ; Heater on E4 Heater

M143 H3 S300 ; Set temperature limit for heater 3 to 300C

; Tooldock D3

M308 S4 P"e6temp" Y"thermistor" A"T3" T100000 B4138 C0 ; Set thermistor

M950 H4 C"!exp.heater6" T4 ; Heater on E5 Heater

M143 H4 S300 ; Set temperature limit for heater 4 to 300C

; >Tools< -------------------------------------------------------------------------------------------------------------------------------

; Tooldock D0

M563 P0 S"T0-None" D4 H1 F3 ; Define tool 0 (Tooldock D0)

G10 P0 X0 Y0 Z0 ; Reset tool 0 axis offsets

G10 P0 R0 S0 ; Reset initial tool 0 active and standby temperatures to 0C

; Tooldock D1

M563 P1 S"T1-None" D3 H2 F4 ; Define tool 1 (Tooldock D1)

G10 P1 X0 Y0 Z0 ; Reset tool 1 axis offsets

G10 P1 R0 S0 ; Reset initial tool 1 active and standby temperatures to 0C

; Tooldock D2

M563 P2 S"T2-Mosquito" D0 H3 F5 ; Define tool 2 (Tooldock D2), Drive 0 (P0) for Tooldock T2, Partcooling fan on Fan3 (Duex)

G10 P2 X0 Y0 Z0 ; Reset tool 2 axis offsets

G10 P2 R100 S210 ; Reset initial tool 2 active and standby temperatures to 210C and 100C

; Tooldock D3

M563 P3 S"T3-None" D1 H4 F6 ; Define tool 3 (Tooldock D3)

G10 P3 X0 Y0 Z0 ; Reset tool 3 axis offsets

G10 P3 R0 S0 ; Reset initial tool 3 active and standby temperatures to 0C

; >Fans< --------------------------------------------------------------------------------------------------------------------------------

M950 F0 C"e0heat" ; Air-Pump on E0-Heater-terminal

M950 F1 C"e1heat" ; LED-Light on E1-Heater-terminal

M950 F2 C"fan2" ; Exhaust-Fans (2 parallel) on Fan2 (Duet2_Wifi)

M950 F3 C"duex.fan3" ; Partcooling Fan Tooldock D0

M950 F4 C"duex.fan4" ; Partcooling Fan Tooldock D1

M950 F5 C"duex.fan5" ; Partcooling Fan Tooldock D2

M950 F6 C"duex.fan6" ; Partcooling Fan Tooldock D3

M950 F7 C"!exp.heater7" ; Watercooling-Pump on E6-Heater (Duex5)

M950 F8 C"fan0" ; Heatsink Fan Tooldock D0 on Fan0 (Duet2)

M950 F9 C"fan1" ; Heatsink Fan Tooldock D1 on Fan1 (Duet2)

M950 F10 C"duex.fan7" ; Heatsink Fan Tooldock D2 on Fan7 (Duex5)

M950 F11 C"duex.fan8" ; Heatsink Fan Tooldock D3 on Fan8 (Duex5)

M106 P0 S0 C"Airpump" ; Air-Pump

M106 P1 S0 C"LED" ; LED LIGHT

M106 P2 S0 C"Exhaust" ; Exhaust-Fans

M106 P3 S0 C"PCF-T0" ; Partcooling Fan Tooldock D0

M106 P4 S0 C"PCF-T1" ; Partcooling Fan Tooldock D1

M106 P5 S0 C"PCF-T2" ; Partcooling Fan Tooldock D2

M106 P6 S0 C"PCF-T3" ; Partcooling Fan Tooldock D3

M106 P7 S0 C"Waterpump" ; Watercooling-Pump

M106 P8 S0 C"Heatsink D0" ;

M106 P9 S0 C"Heatsink D1" ;

M106 P10 T50 H3 C"Heatsink D2" ;

M106 P11 S0 C"Heatsink D3" ;

; Tools other settings -------------------------------------------------------------------------------------------------------------

; Linear Advance

;M572 D0 S0.2 ; pressure advance T0

;M572 D1 S0.2 ; pressure advance T1

M572 D2 S0.04 ; pressure advance T2

;M572 D3 S0.2 ; pressure advance T3

; >Tool offsets G1 X318.1 Y0<

G10 P0 X14.10 Y-60 Z-7.60 ; T0

G10 P1 X13.64 Y-60 Z-7.81 ; T1

G10 P2 X10 Y-60 Z-5.33 ; T2 Mosquito, Bowden 1.75mm

G10 P3 X-9 Y-50 Z-7.88 ; T3

150:100 ; Set maximum instantaneous speed changes

150:100 ; Set maximum instantaneous speed changes