Hi all,

I am trying to understand if I am using rotational axis correctly.

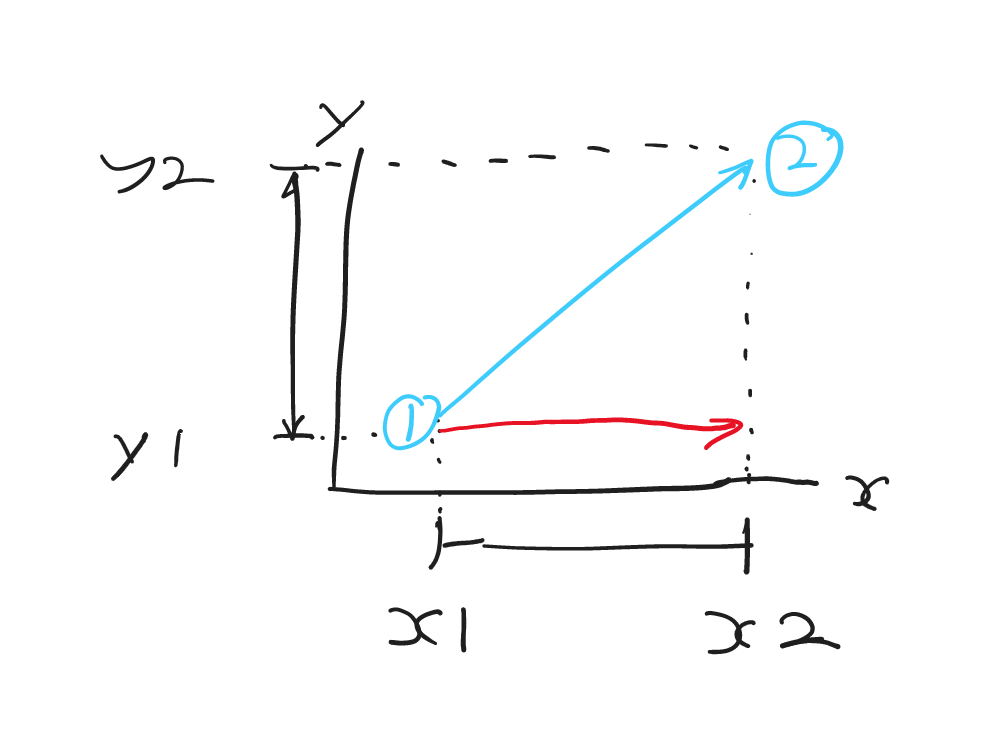

As I understand it, when moving from point 1 to point 2 (blue line) in the drawing below linear axis calculate the X and Y contribution to that move and scale each to the correct amount. But when if I was moving along red line the distance traveled is less.

This means moving 2 axis at one time will result in the each individual axis running slower than if I was running each on its own.

G0 X2 Y2 f80000

will result in each axis moving slower than

G0 X2 f80000

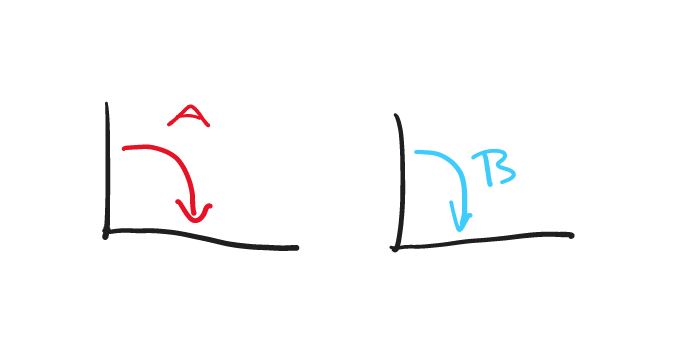

But if I use rotational axis they do not impact on each other in the same way. So in the example below if I rotate A 90 or both A and B 90 both they will run at the same speed?

But when I set up the axis below, they seem to behave like linear axis, as in moving 2 axis at one time by the same amount results in slower movement for both of them, even though from the reference it looks like A,B,C are all treated as rotational axis

M584 A0:2:5:7 B1:3:6:8

M584 C4:9

I have also tried

M584 A0:2:5:7 B1:3:6:8

M584 C4:9 R1

and

M584 A0:2:5:7 R1

M584 B1:3:6:8 R1

M584 C4:9 R1

and

M584 X0:2:5:7 R1

M584 Y1:3:6:8 R1

M584 Z4:9 R1

my complete config file looks like this at the moment

; Configuration file for Duet WiFi (firmware version 3.3)

; executed by the firmware on start-up

;

; for feeder 01-01-2023

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"chip-chop" ; set printer name

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S0 ; physical drive 3 goes backwards

M569 P4 S0 ; physical drive 4 goes backwards

M569 P5 S1 ; physical drive 5 goes forwards

M569 P6 S6 ; physical drive 6 goes forwards

M569 P7 S1 ; physical drive 7 goes forwards

M569 P8 S1 ; physical drive 8 goes forwards

M569 P9 S9 ; physical drive 9 goes forwards

M584 A0:2:5:7 B1:3:6:8 ; set drive mapping

M584 C4:9 R1 ;

M350 C16 A16 B16 I1 ; E6:6:6 ; configure microstepping with interpolation

M92 C40.00 A40.00 B40.00 ; set steps per mm

M566 C180.00 A180.00 B180.00 ; set maximum instantaneous speed changes (mm/min)

M203 C350000.00 A350000.00 B350000.00 ; set maximum speeds (mm/min)

M201 C34000.00 A34000.00 B34000.00 ; set accelerations (mm/s^2)

M906 C1800 A1800 B1800 I10 ; set motor currents (mA) and motor idle factor in per cent

M84 S1 ; Set idle timeout

; RepRapFirmware applies the M204 accelerations to the move as a whole, and also applies the limits set by M201 to each axis and extruder

; Axis Limits

M208 C-10000 A-10000 B-10000 S1 ; set axis minima

M208 C10000 A10000 B10000 S0 ; set axis maxima

; Heaters

M140 H-1 ; disable heated bed (overrides default heater mapping)

so when running

G92 A0 B0 C0 ;reset cutter motor position to 0

G0 C4000 B4000 f80000

G92 A0 B0 C0

G0 A4000 C4000 f80000

G92 A0 B0 C0

G0 A4000 f80000

G92 A0 B0 C0

I was expecting that moving C and B or A and C would result in a move that is the same speed as just moving A, but it dose not

I think I am missing something? Although I cannot see what!

Any help is much appreciated!