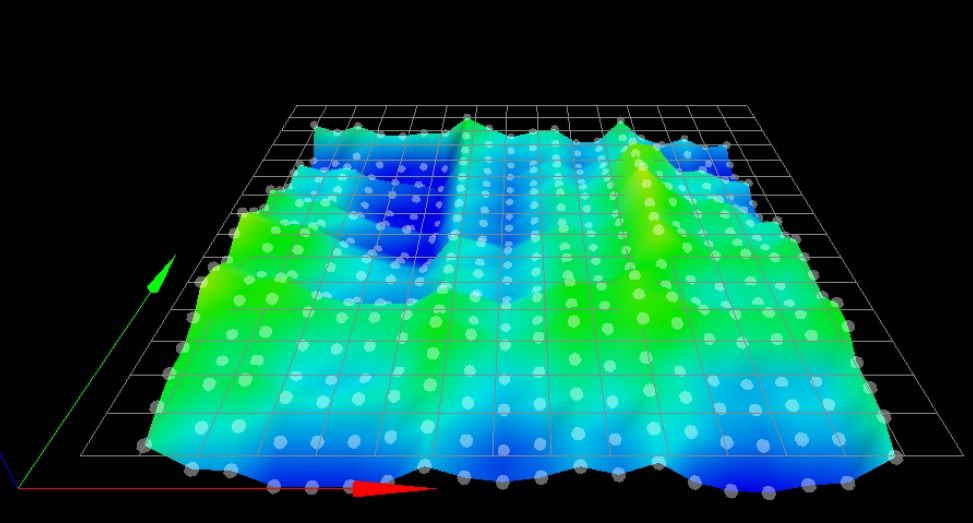

it's a 400 point mesh

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Thu Jun 24 2021 09:31:20 GMT-0600 (Central Standard Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"modix_big_meter" ; set printer name

; Network

M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0 S0 ; physical drive 0 X1 reverse

M569 P1 S1 ; physical drive 1 X2 forward

M569 P2 R-1 ; Physical drive 2 not used

M569 P3 S1 ; physical drive 3 E0 forward

M569 P4 S0 ; physical drive 4 E1 reverse

; additional drives on duex5 expansion board

M569 P5 S0 ; Physical drive 5 Y reverse

M569 P6 S0 ; Physical drive 6 Z1 (0,1000) reverse

M569 P7 S0 ; Physical drive 7 Z2 (0,0) reverse

M569 P8 S0 ; Physical drive 8 Z3 (1000,0) reverse

M569 P9 S0 ; Physical drive 9 Z4 (1000,1000) reverse

;M584 X0 Y1 Z7 E3:4 ; set drive mapping

M584 X0:1 Y5 Z6:7:8:9 U1 E3:4 P3 ; map motors to axis

M671 X-181:-181:1049:1049 Y1066:-58:-58:1066 S10 ; CCW positions of Z motors

;~ M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

;~ M92 X100.00 Y100.00 Z2000.00 E412.00:412.00 ; set steps per mm

;~ M566 X240.00 Y360.00 Z30.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

;~ M203 X9000.00 Y9000.00 Z199.80 E1200.00:1200.00 ; set maximum speeds (mm/min)

;~ M201 X1000.00 Y1000.00 Z120.00 E250.00:250.00 ; set accelerations (mm/s^2)

;~ M906 X1800 Y1800 Z1800 E1000:1000 I30 ; set motor currents (mA) and motor idle factor in per cent

;~ M84 S30 ; Set idle timeout

M350 X16 Y16 Z16 E16 U16 I1 ; Configure microstepping with interpolation

M92 X100.00 Y100.00 Z2000.00 E412.32 U100.00 ; Set steps per mm

M566 X240 Y360 Z30.00 E120.00 U240 P1 ; Set maximum instantaneous speed changes (mm/min)

M203 X9000.00 Y9000.00 Z200.00 E1200.00 U9000.00 ; Set maximum speeds (mm/min)

M201 X1000 Y1000 Z120.00 E250.00 U1000 ; Set accelerations (mm/s^2)

M204 P500 T1000 ; Set print and travel accelerations (mm/s^2)

M906 X1800 Y1800.00 E1000.00 U1800 I30 ; Set motor currents (mA) and motor idle factor in per cent

M906 Z1800.00 I50 ; Set motor currents (mA) and motor idle factor in per cent

M84 S60 X Y U E0 E1 ; Set idle timeout - one minute

; Axis Limits

M208 X0 Y0 Z0 U0 S1 ; set axis minima

M208 X1000 Y1000 Z1000 U1000 S0 ; set axis maxima

; Endstops

;~ M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

;~ M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop

; X1 = X end stop low end

; Y2 = Y end stop high end

; U1 = U end stop low end (U is second X)

; S1 = all active high

; M574 X1 Y2 U1 S1 ; Set active low and disabled endstops

; Z end stop is actually a probe, high limit

; M574 Z2 S2

M574 X1 S1 P"xstop"

M574 Y2 S1 P"ystop"

M574 U1 S1 P"e0stop"

; Z-Probe

M950 S0 C"duex.e6heat" ; create servo pin 0 for BLTouch

;~ M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

M558 P9 C"^zprobe.in" H5 F120 T9000 R0.7 ; set Z probe type to bltouch and the dive height + speeds

;~ G31 P500 X-14 Y21 Z1.081 ; set Z probe trigger value, offset and trigger height

;~ M557 X0:974 Y21:1000 S52 ; define mesh grid

; Set endstops controlled by probe

; heater 7 output used for PWM of BL touch (e6 heat)

;~ M307 H7 A-1 C-1 D-1 ; Disable heater on PWM channel for BLTouch

;~ M558 P9 H5 F120 T9000 A1 R0.7 ; Set Z probe type to bltouch and the dive height + speeds

G31 P500 X-14 Y21 Z1.000 ; Set Z probe trigger value, offset and trigger height(Z-offset)

;M557 X-14:974 Y21:1009 S52 ; Define mesh grid. 400 Points - no longer works with v3, no offset outside of maxima

;

;

; Choose one of these mesh methodas and comment out the other

;M557 X30:970 Y30:970 S104 ; Define mesh grid. 100 points

M557 X-14:974 Y21:1009 S52 ; Define mesh grid. 400 Points

;M557 X-15:973 Y22:1008 S34 ; Define mesh grid. 900 Points

;

;

;

M376 H10 ; Height (mm) over which to taper off the bed compensation

; Heaters

M140 H-1 ; disable heated bed (overrides default heater mapping)

;~ M308 S0 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin e0temp

;~ M950 H0 C"e0heat" T0 ; create nozzle heater output on e0heat and map it to sensor 0

;~ M308 S0 P"e0temp" Y"pt1000"

;~ M950 H0 C"e0heat" T0 ; create nozzle heater output on e0heat and map it to sensor 0

M308 S0 P"spi.cs1" Y"rtd-max31865" R395 F60

M950 H1 C"e0heat" T0 ; heater 0 uses the e0_heat pin and sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S285 ; set temperature limit for heater 0 to 285C

M308 S1 P"e1temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e1temp

M950 H2 C"e1heat" T1 ; create nozzle heater output on e1heat and map it to sensor 1

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S285 ; set temperature limit for heater 1 to 285C

; Fans

M950 F0 C"fan0" Q500 ; T0 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; T1 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S0 H-1 ; set fan 1 value. Thermostatic control is turned off

M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency

M106 P2 S0 H-1 ; set fan 2 value. Thermostatic control is turned off

M950 F3 C"duex.fan3" Q500 ; create fan 3 on pin duex.fan3 and set its frequency

M106 P3 I-1 ; set fan 3 value. Thermostatic control is turned off

M950 F4 C"duex.fan4" Q500 ; create fan 4 on pin duex.fan4 and set its frequency

M106 P4 I-1 ; set fan 4 value. Thermostatic control is turned off

M950 F5 C"duex.fan5" Q500 ; create fan 5 on pin duex.fan5 and set its frequency

M106 P5 S1 H0 T46 ; extruder 0 ; set fan 5 value. Thermostatic control is turned on

M950 F6 C"duex.fan6" Q500 ; create fan 6 on pin duex.fan6 and set its frequency

M106 P6 S1 H1 T46 ; extruder 1 ; set fan 6 value. Thermostatic control is turned on

; apparently these disabled defines still seize the IO; don't define so we can use for LED later

;M950 F7 C"duex.fan7" Q500 ; create fan 7 on pin duex.fan7 and set its frequency

;M106 P7 I-1 ; set fan 7 value. Thermostatic control is turned off

M950 F8 C"duex.fan8" Q500 ; create fan 8 on pin duex.fan8 and set its frequency

M106 P8 I-1 ; set fan 8 value. Thermostatic control is turned off

; Tools

M563 P0 S"E0 Primary" D0 H1 F0 ; define tool 0, E0 drive, heater 1, fan 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"E1 SEcondary" D1 H2 F1 ; define tool 1

G10 P1 X-0.2 Y52.5 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M501 ; load saved parameters from non-volatile memory

; Automatic power saving____________________________________________

M911 S22.5 R29.0 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss. Power Failure Pause

; Custom settings___________________________________________________

;M591 D0:1 P1 C4 S1 ; Regular filament sensor for E0 and E1

; disabled, fixme

; _______________GPIOs____________________

; LED strip on GPIO 'P1', duex fan7 output

M950 P1 C"duex.fan7" Q500

I just had to rewrite config.g to allow the new firmware, maybe I missed some things. That call to deploy probe might be redundant (I think deployprobe.g and should be called automatically?) Initially I was having conflicts with the probe pin output and a GPIO for LEDs conflicting, since it seems the probe pin is treated as a GPIO as well and they can't both be logical 'P0'. It is a bl-touch probe. Making the LED GPIO 'P1' resolved that, anyway. It's a 400 point map currently. Mechanical adjustment of the bed could be somewhat better.

these macros aren't my creation so I'm not positive

tilt macro

M42 P0 S1 ; Main LED on

G90 ;Absolute Positioning

G10 P0 S0

G10 P1 S0

if !move.axes[0].homed || !move.axes[1].homed ; If the printer hasn't been homed, home it

G28 XY ; home y and x

;

G28 Z ; home z

;

M561 ; clear any bed transform

echo "Starting Bed Tilt Calibration"

M98 P"bed_screws.g" ; perform bed tramming

echo "BTC: 1 - Difference was " ^ move.calibration.initial.deviation ^ "mm"

;

;

; Select one or the other of the two types of while loops, commenting out the inactive loop

; while move.calibration.initial.deviation >= 0.01 ; perform additional bed tilt calibrations if previous deviation was over 0.01mm

while iterations < 6 ; perform additional based on number of cycles

echo "Cycle " ^ iterations + 1

if iterations = 6

abort "Too many tilt calibration attempts"

; ; the following moveds the bed up and down before each calibration cycle to test if the bed z-steppers are slipping

;G91 ; relative Positioning

;G1 Z100 F200 ; move bed down 100mm

;G1 Z-100 F200 ; move bed up 100mm

;G90 ; absolute Positioning

; ; end stepper slip moves

M98 P"bed_screws.g" ; perform bed tilt calibration

echo "BTC: " ^ iterations + 2 ^ " - Difference was " ^ move.calibration.initial.deviation ^ "mm"

continue

;

G28 Z

echo "Bed Tilt Calibration complete"

mesh probing macro

M561

G28 ; home all

M561 ; clear any bed transform

M42 P0 S1 ; Main LED on

M98 P"0:/macros/Calibration/03_Automatic_Bed_Tilt_Calibration_ABTC" ; perform bed tilt calculations

M400

;

; Mesh Grid Defined in config.g

;

G28 ; home all

M561 ; clear any bed transform

echo "Performing Bed Mesh Compensation Mapping"

G29 S0 ; probe the bed and enable compensation

G4 P999

G28 ; home all

echo "Bed Mesh Compensation Mapping complete"

M291 S2 P"The bed plate is calibrated and the 400 point heightmap is loaded"

Do you think there will be large error from doing G30 at home (~0,1000) instead of the middle of the bed?