@barn-metal-fab

Seems my post of the config.g did not work as I expected... here it is:

; Configuration file for Duet 3 (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Thu Oct 08 2020 12:57:51 GMT-0700 (Pacific Daylight Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet 3" ; set printer name

M669 K1 ; select CoreXY mode

; Drives

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M569 P0.2 S1 ; physical drive 0.2 goes forwards

M569 P0.3 S1 ; physical drive 0.3 goes forwards

M569 P0.4 S1 ; physical drive 0.4 goes forwards

M584 X0.0 Y0.1 Z0.2 E0.3:0.4 ; set drive mapping

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z640.00 E840.00:840.00 ; set steps per mm

M566 X3000.00 Y3000.00 Z250.00 E1000.00:1000.00 P1 ; set maximum instantaneous speed changes (mm/min)

M203 X18000.00 Y18000.00 Z1000.00 E4000.00:4000.00 ; set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z50.00 E100.00:100.00 ; set accelerations (mm/s^2)

M906 X1800 Y1800 Z3000 E1200:1200 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S20 ; Set idle timeout; Trinamic Drive Tuning

; Tune tpwmthrs (V) so stealthchop runs at appropriate speeds

; and tune thigh (H) to avoid shifting into fullstep mode

M569 P0.0 V40 H5 ; X - Set tpwmthrs so StealthChop runs up to 105.5mm/sec

M569 P0.1 V40 H5 ; Y - Set tpwmthrs so StealthChop runs up to 105.5mm/sec

...

M915 X Y T20000 ; Set CoolStep threshold super low

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X452 Y252 Z420 S0 ; set axis maxima

; Endstops

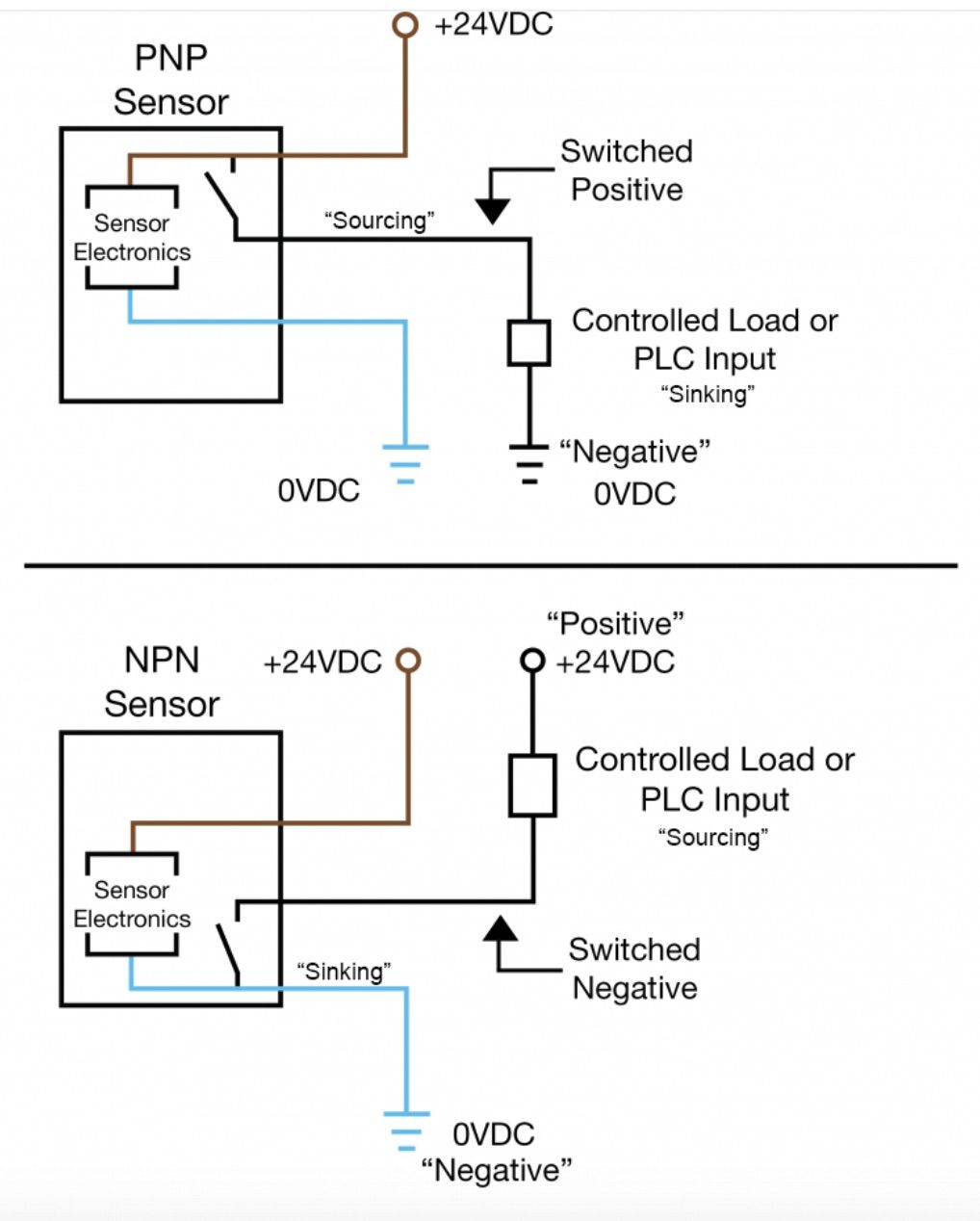

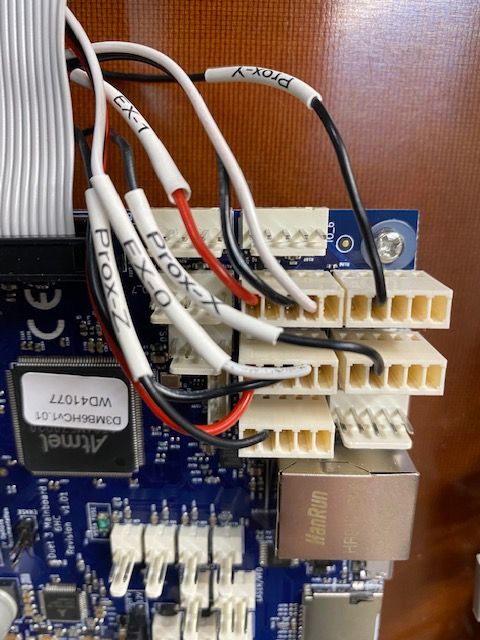

M574 X2 S1 P"io1.in" ; configure active-high endstop for high end on X via pin io1.in

M574 Y2 S1 P"io2.in" ; configure active-high endstop for high end on Y via pin io2.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z with active-high

;Filament Sensors

M591 D0 P1 C"io4.in" S1 ;Set Extruder "0" to Pin io4-in to indicate High when filament present

M591 D1 P1 C"io5.in" S1 ;Set Extruder "1" to Pin io5-in to indicate High when filament present

; Z-Probe

M558 P5 C"^io3.in" H2 F200 T4000 ; set Z probe to switch and dive height + speeds - active high (^io3.in ^=pullup resistor)

G31 P1000 X0 Y0 Z5.77 ; hold G31 P1000 X-5.35 Y-33.3 Z5.77 ; set Z probe trigger value, offset and trigger height. Set the Sensor X & Y offset from Left nozzle (Tool#0)

M557 X30:430 Y10:250 S20 ; define mesh grid

; Heaters

M308 S0 P"temp0" Y"pt1000" R2200 ; configure sensor 0 as PT1000 on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S150 ; set temperature limit for heater 0 to 150C

M308 S1 P"temp1" Y"pt1000" R2200 ; configure sensor 1 as PT1000 on pin temp1

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S450 ;Set Tool 1 to max Tempt of 450C

M308 S2 P"temp2" Y"pt1000" R2200 ; configure sensor 2 as PT1000 on pin temp2

M950 H2 C"out2" T2 ; create nozzle heater output on out2 and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S450 ;Set Tool 2 to max Tempt of 450C

;CHAMBER HEATER

M308 S3 P"temp3" Y"pt1000" R2200 ; configure sensor 3 as PT1000 on pin temp3

M950 H3 C"out3" T3 ; create bed heater output on out0 and map it to sensor 3

M141 H3 ; Define heater h3 as chamber heater

M301 H3 P-1 ; Disable PID settings to use bang-bang

M143 H3 S120 ; set temperature limit for heater 3 to 120C

M307 H3 B1 D60 ; Set H3 to Bang-Bang and Dead zone to 60 seconds

; Fans

M950 F0 C"out4" Q500 ; create fan 0 on pin out4 and set its frequency

M106 P0 S0 H1 T45 ; set fan 0 value. Thermostatic control is turned on

;Set pseudo Fan7 to out7 to ouput 12V for powering timed relay

M950 F7 C"out7"

; Tools

M563 P0 S"Mosquito Main 0" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R165 S205 ; set initial tool 0 active and standby temperatures

M563 P1 S"Mosquito Support 1" D1 H2 F0 ; define tool 1

G10 P1 X10.7 Y-0.2 Z0 ; set tool 1 axis offsets - Set Z to a -0.1mm height to adjust for hard limit on adjustment -- remove at carriage rebuild.

G10 P1 R165 S205 ; set initial tool 1 active and standby temperatures

;Pressure Advance

M572 D0 S0.85

M572 D1 S0.975

;---------------CUSTOM SETTINGS----------------

;M501