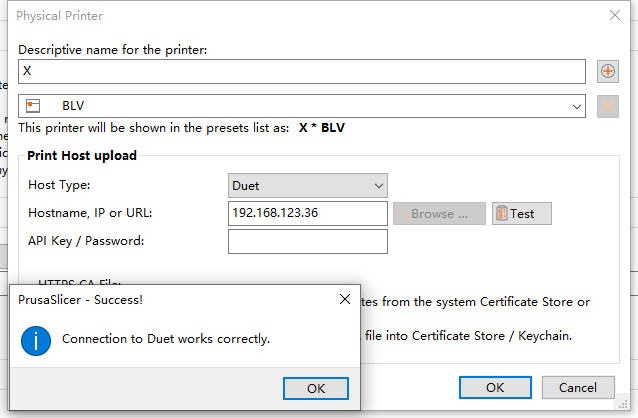

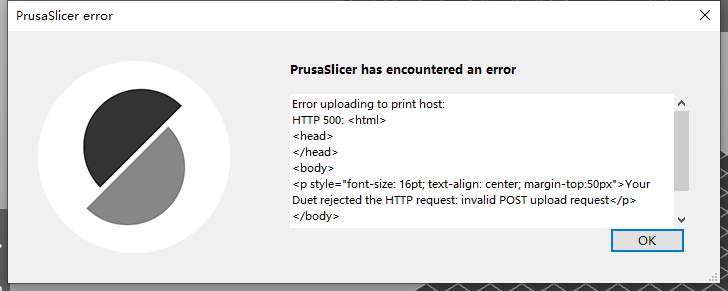

I use prusaslicer for stl processing, but when I click upload, I get a failure message

Error uploading to print host:

HTTP 500: <html>

<head>

</head>

<body>

<p style="font-size: 16pt; text-align: center; margin-top:50px">Your Duet rejected the HTTP request: invalid POST upload request</p>

</body>

Here are some pictures

The plug-in of cura is normal. If I use prusa on another computer, it is also normal. I don’t know where the problem is.

My prusaslicer version is 2.3.1, duet and dwc are rrf3

Latest posts made by guanjian

-

upload error from prusaslicerposted in Duet Web Control

-

RE: Laser control failedposted in Laser Cutters

@guanjian ; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Wed Aug 05 2020 10:37:58 GMT+0800 (中国标准时间); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"BLV" ; set printer name机器名字

M669 K1 ; select CoreXY mode机器模式; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S1 ; enable FTP

M586 P2 S1 ; enable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards,X电机方向和位置

M569 P1 S0 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S0 ; physical drive 3 goes forwards,挤出机方向和位置

M584 X0 Y1 Z2:4 E3; two Z motors connected to driver outputs Z and E1,两个Z电机链接到Z和E1

M350 X128 Y128 Z128 E128 I0 ;不插值的细分

M92 X800.00 Y800.00 Z5120 E3075 ; set steps per mm,脉冲数值

M566 X720.00 Y720.00 Z12.00 E120.00 ; set maximum instantaneous speed changes (mm/min),突变速度

M203 X6000 Y6000 Z120.00 E1200.00 ; set maximum speeds (mm/min),最大速度

M201 X500.00 Y500.00 Z3.00 E250.00 ; set accelerations (mm/s^2),加速度

M906 X1550 Y1500 Z1500 E800 I30 ; set motor currents (mA) and motor idle factor in per cent,电机电流

M84 S30 ; Set idle timeout,解锁等待

M572 D0 S0.4 ;挤出提前值/延迟值,远程挤出配置

; Axis Limits

M208 X-15 Y-30 Z0 S1 ; set axis minima

M208 X310 Y300 Z400 S0 ; set axis maxima

M671 X-20:220 Y0:0 S0.5 ; leadscrews at left (connected to Z) and right (connected to E1) of X axis; Endstops

M574 X1 S1 P"!xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"!ystop" ; configure active-high endstop for low end on Y via pin ystop

;M574 Z1 S1 P"!zstop+!e1stop" ; configure active-high endstops for low end on Z via pins zstop and e1stop,双Z双限位配置

M574 Z1 S1 P"!zstop" ; configure active-high endstop for low end on Z via pin zstop

M591 P1 C"e0stop" S1 D0 ; filament monitor connected to E0 endstop,断料检测; Z-Probe

;M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed

M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed

;G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

;M558 P5 H5 I1 F120 T6000 ; set Z probe type to switch and the dive height + speeds

M557 X50:250 Y50:-300 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M501 ;PID校准保存; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 C"模型风扇" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 C"LED灯" S1 H-1 ; set fan 1 name and value. Thermostatic control is turned off

M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency

M106 P2 C"喉管风扇" S0.8 H-1 ; set fan 2 name and value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

-

RE: Laser control failedposted in Laser Cutters

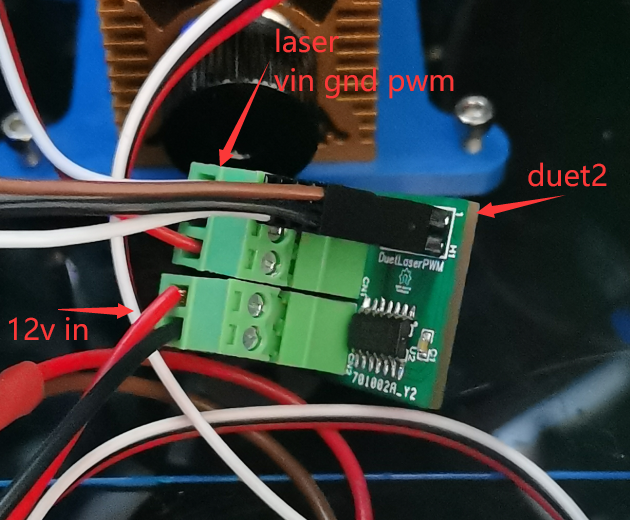

i use a 4p jumper to connect the duet and laser board,

-

RE: Laser control failedposted in Laser Cutters

@phaedrux M122

=== Diagnostics ===

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.3beta3 (2021-04-22 16:27:28) running on Duet WiFi 1.02 or later

Board ID: 08DGM-9T6BU-FG3S4-6JKF0-3SD6L-1URRF

Used output buffers: 13 of 24 (13 max)

=== RTOS ===

Static ram: 23156

Dynamic ram: 75356 of which 12 recycled

Never used RAM 15892, free system stack 186 words

Tasks: NETWORK(ready,11.2%,211) HEAT(delaying,0.0%,294) Move(notifyWait,0.1%,214) MAIN(running,87.5%,463) IDLE(ready,1.2%,19), total 100.0%

Owned mutexes: WiFi(NETWORK)

=== Platform ===

Last reset 00:00:18 ago, cause: power up

Last software reset at 2021-04-25 11:24, reason: User, GCodes spinning, available RAM 15892, slot 2

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

Aux0 errors 0,0,0

Step timer max interval 0

MCU temperature: min 23.5, current 24.8, max 25.2

Supply voltage: min 24.1, current 24.2, max 24.3, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0

Driver 0: position 0, standstill, SG min/max not available

Driver 1: position 0, standstill, SG min/max not available

Driver 2: position 0, standstill, SG min/max not available

Driver 3: position 0, standstill, SG min/max not available

Driver 4: position 0, standstill, SG min/max not available

Driver 5: position 0

Driver 6: position 0

Driver 7: position 0

Driver 8: position 0

Driver 9: position 0

Driver 10: position 0

Driver 11: position 0

Date/time: 2021-04-25 11:25:23

Cache data hit count 676672059

Slowest loop: 5.36ms; fastest: 0.18ms

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 20.0MBytes/sec

SD card longest read time 1.3ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 83, maxWait 0ms, bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1 -1 -1

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

Daemon is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty.

=== Filament sensors ===

Extruder 0 sensor: ok

=== Network ===

Slowest loop: 81.88ms; fastest: 0.00ms

Responder states: HTTP(2) HTTP(2) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions

HTTP sessions: 1 of 8- WiFi -

Network state is active

WiFi module is connected to access point

Failed messages: pending 0, notready 0, noresp 0

WiFi firmware version 1.23

WiFi MAC address cc:50:e3:27:3f:07

WiFi Vcc 3.42, reset reason Turned on by main processor

WiFi flash size 4194304, free heap 19608

WiFi IP address 192.168.123.36

WiFi signal strength -45dBm, mode none, reconnections 0, sleep mode modem

Clock register ffffffff

Socket states: 4 4 0 0 0 0 0 0

This is M122's reply

- WiFi -

-

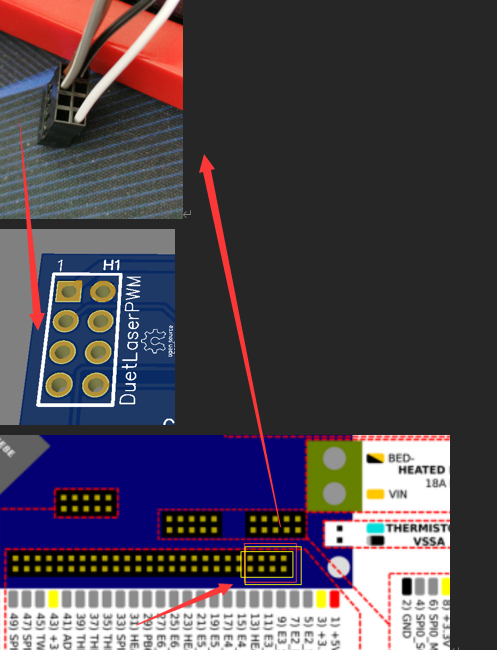

Laser control failedposted in Laser Cutters

I made the circuit board according to the instructions on the official website, but after connecting it to the duet, it can’t work properly. I can’t control the laser switch and intensity using instructions such as M3.M5 G1 Sx.

I have measured it, the power supply is normal, and my laser module also meets the specifications. The pwm port has a 5V output, no matter what G code I use, the 5V voltage does not change.

I made M452 C "exp.heater3" R255 F200 into a macro, and I opened it when I needed it.

The above is generated using Google Translate. If there is any unclear description, please let me know.