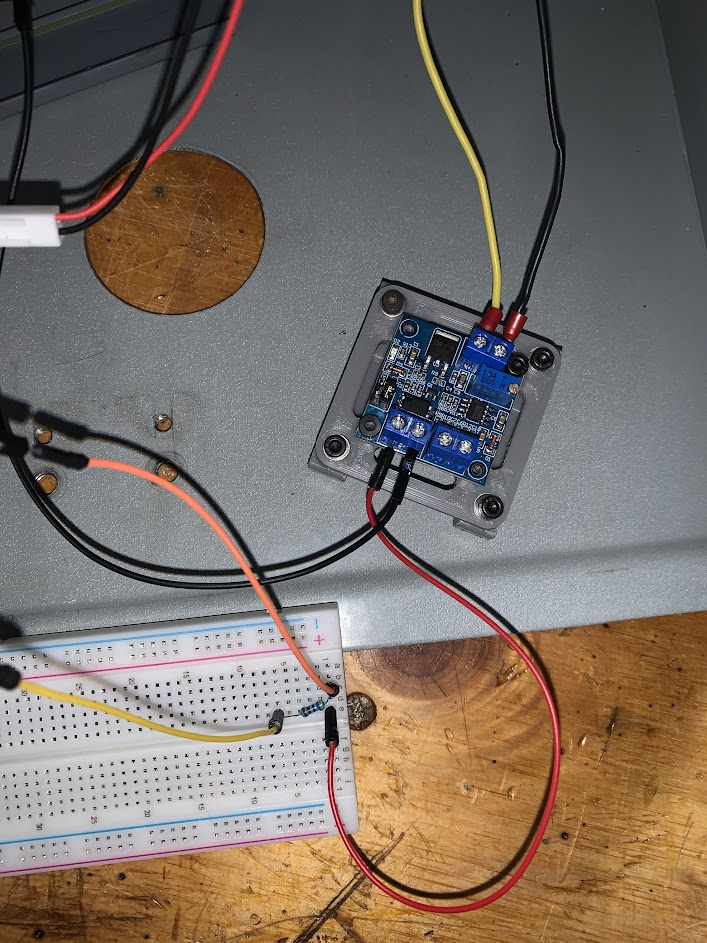

@dc42 After wiring one backwards and blowing a capacitor and ordering another one I finally got spindle speed control. Thanks everyone.

If its help to anyone in the future here is my config for the spindle.

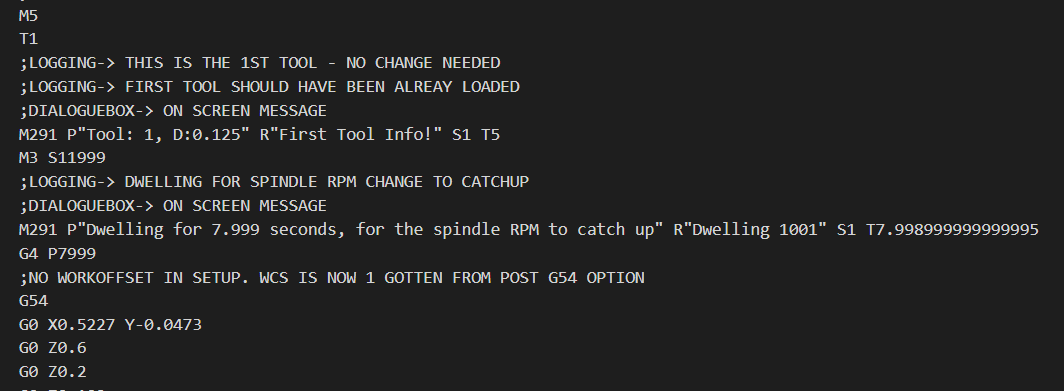

; Attemping to setup spindle

; CNC Mode (NB for Firmware 3.3+)

M453 ; CNC Mode

; Configure Tool 0 as the CNC Spindle

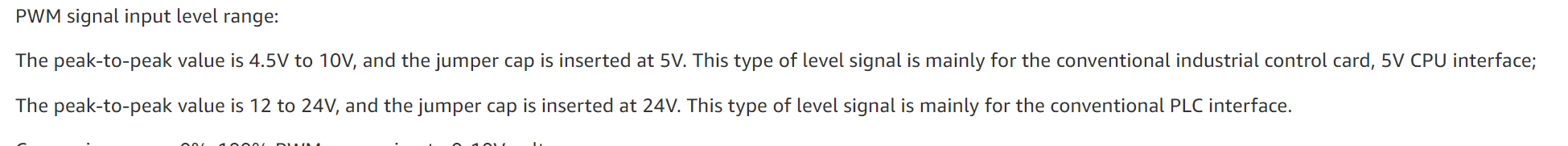

M950 R0 C"e0heat" Q2000 L12000 ; Create spindle index 0 with

; inverted PWM output on E0 heater pin

; and spindle speed of 12000 rpm at maximum PWM

M563 P0 R0 S"Spindle" ; Create Tool 0 with Spindle 0 and call it Spindle

G10 P0 X0 Y0 Z0 ; Set Tool 0 axis offsets

M568 P0 F0 ; Set Tool 0 to default RPM of 0

T0 ; Select Tool 0