-

@jack_kelley moved the the CNC forum.

It looks like the PWM to analog module has two options:

The peak-to-peak value is 4.5V to 10V, and the jumper cap is inserted at 5V. This type of level signal is mainly for the conventional industrial control card, 5V CPU interface;

The peak-to-peak value is 12 to 24V, and the jumper cap is inserted at 24V. This type of level signal is mainly for the conventional PLC interface.The heater outputs on the Duet 2 should have VIN voltage on the VIN pin and the negative pin is switched ground (using PWM)

-

@t3p3tony Thanks for your help, I wasn't sure if I should have put it in there.

I am also using this cnc to expand my skills so at the moment I am not very competent with electronics. Do i need to plug into the duet in another place? I tried the jumper in both settings and they both produced the same result of a constant 5V

-

@jack_kelley You should use an output pin that is NOT a heater pin since the heater pin switches the ground instead of the signal pin.

They any other I/O pin that can be used as a PWM output on your board.

-

@jack_kelley said in 500 Watt chinese spindle setup:

I tried the jumper in both settings and they both produced the same result of a constant 5V

I thought you meant the Duet produced constant 5V. Now I see you meant the spindle control.

There are two options for a PWM output from the Duet 2. Either 3.3V PWM on the expansion header (here is an example using that):

M950 R0 C"!exp.heater3" L12000 ; Create spindle index 0, with PWM pin on heater 3 and 12000 RPM achieved at full PWM M563 P1 S"Spindle 1" R0 ; Create tool 1 with spindle 0 and call it "Spindle 1"or the negative terminal of the heater or fan headers being PWMed.

-

@t3p3tony Thanks for your help, Ill give that a shot tonight.

-

@t3p3tony The converter cannot take a 3.3V signal, is there an option for a 5V pwm on these boards?

-

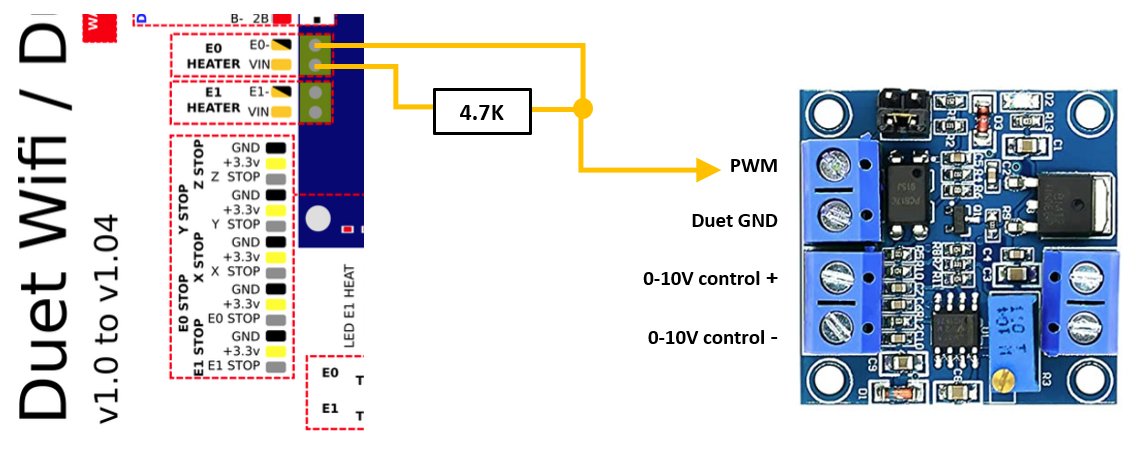

To get the necessary 5V signal for this converter board you’ll need to add a pull up resistor.

@alankilian described a way of doing this here:

https://forum.duet3d.com/post/242329

The OP on this topic found @alankilian’s method worked with a 4.7K resistor value.

-

@cjm I have read through that thread and still dont quite understand where to put the resistor. Is there a schematic or a picture of where it should be anywhere?

-

@jack_kelley

This connection for the pull up resistor should work:

As this connection inverts the polarity of the PWM signal I think you will probably need to add an exclamation mark in front of the "e0heat" pin reference in your M950 config command, along the lines of:

; CNC Mode (NB for Firmware 3.3+) M453 ; CNC Mode ; Configure Tool 0 as the CNC Spindle M950 R0 C"!e0heat" Q2000 L0:12000 ; Create spindle index 0 with ; inverted PWM output on E0 heater pin ; and spindle speed of 12000 rpm at maximum PWM M563 P0 R0 S"Spindle" ; Create Tool 0 with Spindle 0 and call it Spindle G10 P0 X0 Y0 Z0 ; Set Tool 0 axis offsets M568 P0 F0 ; Set Tool 0 to default RPM of 0 T0 ; Select Tool 0 -

@cjm Still only getting around 5V no matter is I run an M5 or M3 at full speed. Tried jumper cap at both locations. The only other thing i forgot to test was taking out the ! that you didnt seem sure needed to be there.

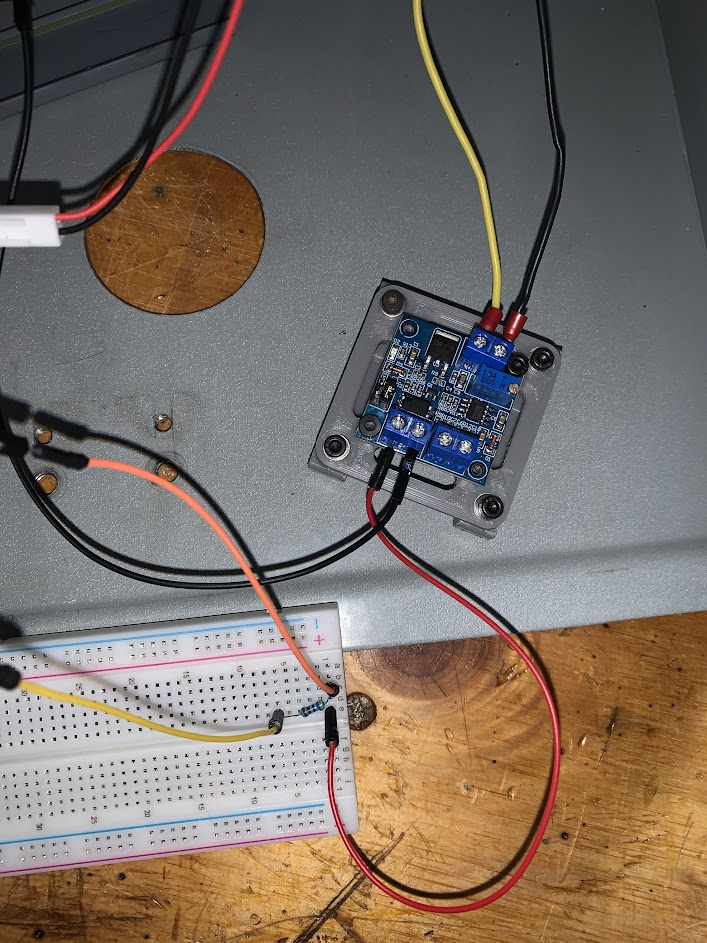

Color code

Orange- E0-

Yellow at breadboard-Vin E0

Red to PWM on converter

Yellow 24V

Black Ground

Maybe the pwm to analog converter is fried?

-

@jack_kelley OK, then I’d suggest using a multimeter to check:

a) that you have the correct DC input voltage on your Duet VIN (12V or 24V?)

b) that the output from the Duet E0 heater pin is behaving as expected by disconnecting the PWM converter board but leaving the 4.7K resistor in circuit and then measuring the DC voltage on the E0 heater pin for each of the following commands:

Command Should give M3 0 Duet VIN M3 6000 Duet VIN/2 M3 12000 0VIf both a) and b) check out, then your PWM board is probably dead.

-

@Jack_kelley you need to use this connection between the PWM input connector of the converter board and the Duet:

- PWM pin to VIN on the Duet E0 output

- GND pin on the PWM input connector to E0- on the Duet (and nowhere else)

Select the jumper position on the converter board so that the PWM input accepts 12 to 24V.

This connection is OK for converter boards with optically isolated inputs, such as the one you have. The GND pin on the PWM input connector is a misleading name, it should be called PWM- or something like that.

-

@dc42 From the image of the PCB, I believe this is another of those converter boards with an opto-isolator whose purpose is negated by being connected to ground on the board.

Hence the @alankilian connection with a pull up resistor is needed. -

@cjm I see what you mean. Best option may be to use a scalpel or similar on the PCB to isolate the GND pins on the PWM connector and opto isolator; or buy a PWM converter without such an obvious design flaw. Having a shared ground between the Duet and a 500W spindle controller would be a bad idea.

-

@dc42 The board looks to be double sided so one would have to desolder the terminal and cut both sides of the PCB - might be doable but not straightforward.

I agree that having a common Duet-VFD ground is not optimal, but this board has used by others successfully using the pull-up resistor approach.

A properly opto-isolated VFD interface board that provides a 0-10v analogue control signal and RUN, FWD/REV control signals (and ideally rpm feedback) would be a useful add-on for the growing Duet eco-system and make life simpler for many CNC users.

-

@cjm said in 500 Watt chinese spindle setup:

The board looks to be double sided so one would have to desolder the terminal and cut both sides of the PCB - might be doable but not straightforward.

Is there really a ground plane on both sides? Usually a ground plane is on one side only.

I think this style of converter board is OK. I have one, so I can check.

EDIT: confirmed, the input is isolated from the output on this type.

-

@dc42

I have one of those coming today, it has a 3.3V PWM input so it should be much more simple to setup. Ill update when I give it a shot. Thanks for the help everyone.https://www.amazon.com/dp/B079B5MRQC?psc=1&ref=ppx_yo2_dt_b_product_details

-

@jack_kelley said in 500 Watt chinese spindle setup:

@dc42

I have one of those coming today, it has a 3.3V PWM input so it should be much more simple to setup. Ill update when I give it a shot. Thanks for the help everyone.https://www.amazon.com/dp/B079B5MRQC?psc=1&ref=ppx_yo2_dt_b_product_details

The one I have has a jumper for either 5V or 24V input. I don't know whether on the 5V setting it will work with 3.3V input. Using the 24V position, you can connect it to a heater or fan output as I suggested earlier (which as @cjm pointed out, won't work with the other sort).

-

@dc42 After wiring one backwards and blowing a capacitor and ordering another one I finally got spindle speed control. Thanks everyone.

If its help to anyone in the future here is my config for the spindle.

; Attemping to setup spindle

; CNC Mode (NB for Firmware 3.3+)

M453 ; CNC Mode; Configure Tool 0 as the CNC Spindle

M950 R0 C"e0heat" Q2000 L12000 ; Create spindle index 0 with

; inverted PWM output on E0 heater pin

; and spindle speed of 12000 rpm at maximum PWMM563 P0 R0 S"Spindle" ; Create Tool 0 with Spindle 0 and call it Spindle

G10 P0 X0 Y0 Z0 ; Set Tool 0 axis offsets

M568 P0 F0 ; Set Tool 0 to default RPM of 0

T0 ; Select Tool 0 -

@dc42 would that board be ok to use with the spindle drive on my denford novamil and novaturn?

As I understand it the 0-10v floats on my spindle drive at about 110v above controller vref on both machines.

For my previous attempts at controller conversion I ended up turning a pot with a servo. I gave up on that front and reverted to the OEM controller but have been looking for a better onboard controller solution ever since.

If the 1HLC driver beta goes well I'm hoping to convert both my denfords over to Duet with linear scales, so I've started looking into this sort of thing again.

Any thoughts would be much appreciated.

Cheers

Barry M undefined)

undefined)

undefined)

undefined)