@dc42

I just confirmed it is in cnc mode and 3.3.

I'm going to try adding more g1's to the program and see what happens

Posts made by jmorganmkm

-

RE: Help configuring vers 3.3posted in CNC

-

RE: Help configuring vers 3.3posted in CNC

@dc42

I think the machine homes correctly and I am able to jog the machine in the correct axis and distance. The second file i uploaded was the start of a snowflake engrave but instead of lowering z to -.04 and moving the xy it instead lowers z to -.04 and than raises it again, moves to another position and drops z again, raises it and moves xy.

My next idea is to put it into cartesian mode but i thought that was default. here is my homeall; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Tue Apr 20 2021 01:19:12 GMT-0600 (Mountain Daylight Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X-767 Y-945 F1800 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X10 Y10 F6000 ; go back a few mm G1 H1 X-20 Y-20 F360 ; move slowly to X and Y axis endstops once more (second pass) G1 H1 Z-95 F360 ; move Z down stopping at the endstop G90 ; absolute positioning G92 Z0.5 ; set Z position to axis minimum (you may want to adjust this) ; Uncomment the following lines to lift Z after probing G91 ; relative positioning G1 Z5 F100 ; lift Z relative to current position G90 ; absolute positioning -

Help configuring vers 3.3posted in CNC

Hello everyone,

I recently acquired an older model MPCNC from a friend and foolishly updated the firmware and lost everything.

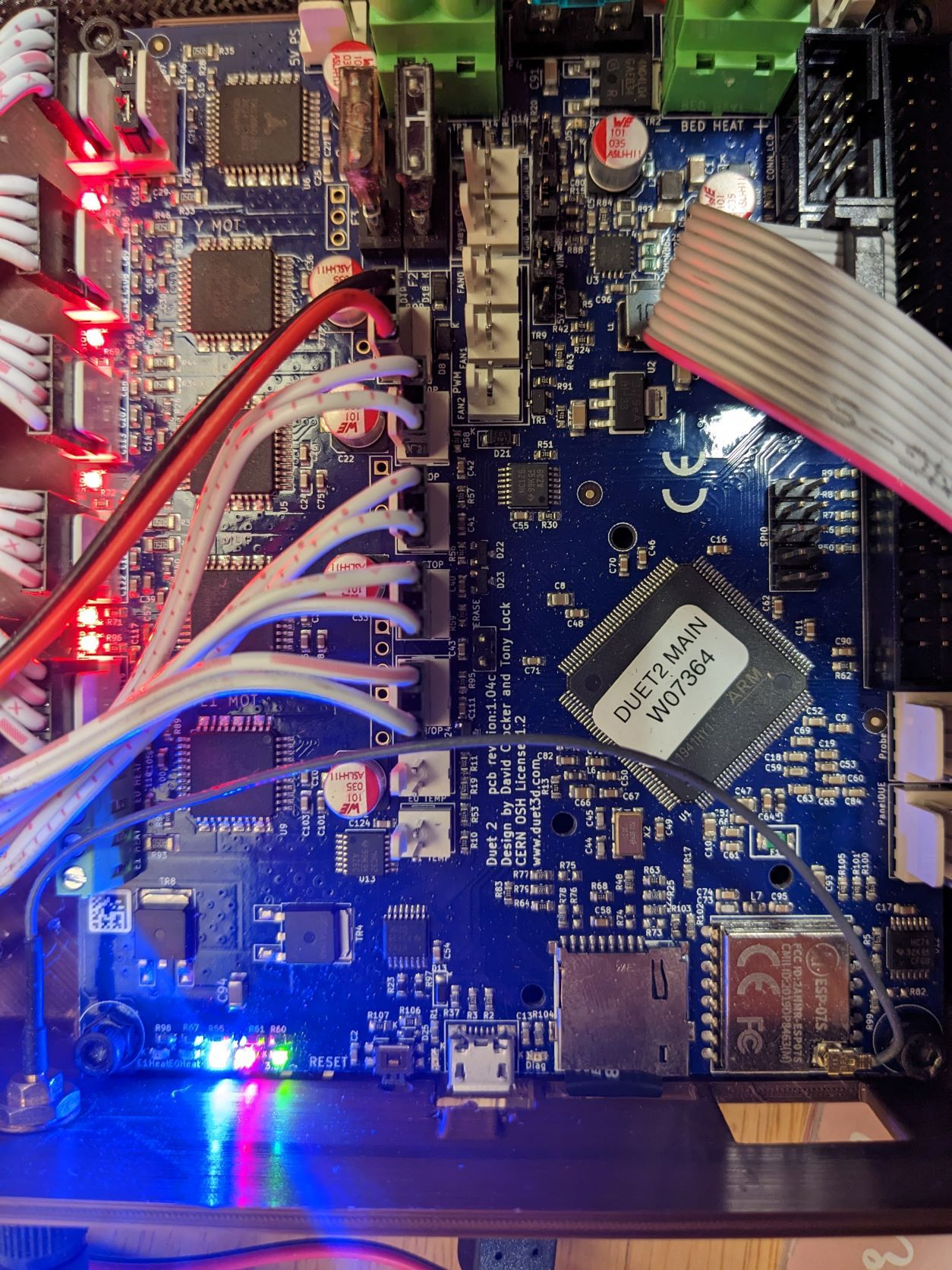

I have zero experience with 3d printing but my day job is programming and setting up HAAS and Fanuc cnc milling machines for an aerospace company. Somehow i figured out how to configure the drive and endstops for the x ( 0 and 3 ) and the y (1 and 4). Everything homes correctly but when i try to run a simple program the router doesn't read the x and y correctly and goes up and down on the z. any help is appreciated. I found doing the research to be extremely difficult trying to sort through all the versions so just posting current config.g and homeall files would be extremly helpful.; Configuration file for Duet WiFi (firmware version 2.03) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.15 on Tue Jan 24 2023 21:08:30 GMT-0500 (Eastern Standard Time) ; General preferences M575 P1 S1 B57600 ; enable support for PanelDue G90 ; send absolute coordinates... M550 P"MPCNC" ; set printer name ;THIS IS A SLOPPY AND PROB WRONG CONFIG FILE ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forward M569 P1 S0 ; physical drive 1 goes REVERSE M569 P2 S0 ; physical drive 2 goes REVERSE M569 P3 S0 ; physical drive 3 goes REVERSE M569 P4 S1 ; physical drive 4 goes forward M584 X0:3 Y1:4 Z2 ; configure drive mapping M350 X16 Y16 Z16 ; configure microstepping with interpolation M92 X100.00 Y100.00 Z400.00 ; set steps per mm M566 X900.00 Y900.00 Z300.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z800.00 U900 V900.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z40.00 U500.00 V500.00 ; set accelerations (mm/s^2) M906 X800.00 Y800.00 Z800.00 ; set motor currents (mA) M84 S10 ; Disable motor idle current reduction ; Axis Limits M208 X0 Y0 Z-100 U0 V0 S1 ; set axis minima M208 X770 Y260 Z200 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop+e0stop" ; configure endstop M574 Y1 S1 P"ystop+e1stop" ; configure endstop M574 Z1 S1 P"!zstop" ; configure endstop ; Z-Probe M558 P5 C"zstop" H5 F120 T3000 ; Z probe connected to Duet 2 Z endstop input ; Heaters M140 H-1 ; Disable heated bed ; Tools ; Tools M563 P0 S"Router" R0 ; Define the router as tool 0 M453 ; Set CNC Mode M575 P1 S1 B57600 ; Enable PanelDUE at 57600 BPSPLEASE EXCUSE MY SLOPPY CODING

How i think a program should startG20 G90 G0X1.3848Y1.0000 G1Z-0.0400F10.0 X1.3846Y0.9931F35.0 X1.3841Y0.9863 X1.3832Y0.9795