I checked the content and it's there and I have tried not turning on the hot bed and hotend. Funny thing is it prints when I teither it by usb and use simplify3d. But the calibration doesn't actually do anything and results in a very high nozzle. I just find it weird that it was working perfectly fine before and i was printjng everything then all of a sudden this happens

Posts made by Luxmotion

-

RE: Printer wont print even after a new config fileposted in General Discussion

-

RE: Printer wont print even after a new config fileposted in General Discussion

Ok so I tried it and placed T0 in the start up section on two gcode files that i have printed before and still didn't do anything stated it uploaded 100% printer doesn't re-home and start calibration and both the bed and hot end switch off and start to cool down.

-

RE: Printer wont print even after a new config fileposted in General Discussion

I'll give it a try tomorrow but I don't understand why it is doing it all of a sudden, but I will see maybe I'll just but it in the start file from the beginning, And see if it works thanks deckingman

-

Printer wont print even after a new config fileposted in General Discussion

So I'm in the process of fine tuning my Prints and I have started making some parts for my car.

Finally get a good model happening and when I Hit the button to Upload and print. It up loads the Gcode file and then turns the hotend and bed off and tells me the print has completed.The printer doesnt even home or try to do a preprint calibration.

I was printing 2 days ago turned it off and then came to print today and got given this.

Any ideas?

Heres my config file:

[[language]] ; Configuration file for Duet WiFi (firmware version 1.17) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool on Wed Aug 09 2017 11:08:15 GMT+0800 (W. Australia Standard Time) ; General preferences M111 S0 ; Debugging off G21 ; Work in millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M555 P2 ; Set firmware compatibility to look like Marlin ;*** The homed height is deliberately set too high in the following - you will adjust it during calibration. M665 R150 L310 B130 H320 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; Put your endstop adjustments here, or let auto calibration find them M208 Z-5 S1 ; Set minimum Z ; Endstops M574 X2 Y2 Z2 S1 ; Define active high microswitches M558 P1 X0 Y0 Z0 H5 F200 T2400 ; Set Z probe type to unmodulated, the axes for which it is used and the probe + travel speeds G31 P500 X0 Y0 Z0.367 ; Set Z probe trigger value, offset and trigger height M557 R80 S10 ; Define mesh grid ; Drives M569 P0 S0 ; Drive 0 goes forwards M569 P1 S0 ; Drive 1 goes forwards M569 P2 S0 ; Drive 2 goes forwards M569 P3 S0 ; Drive 3 goes forwards M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation M92 X100 Y100 Z100 E420 ; Set steps per mm M566 X1200 Y1200 Z1200 E1200 ; Set maximum instantaneous speed changes (mm/min) M203 X18000 Y18000 Z18000 E1200 ; Set maximum speeds (mm/min) M201 X1000 Y1000 Z1000 E1000 ; Set accelerations (mm/s^2) M906 X1000 Y1000 Z1000 E1200 I60 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Heaters M143 S260 ; Set maximum heater temperature to 260C M305 P0 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 0 M305 P1 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 1 ; Tools M563 P0 D0 H1 ; Define tool 0 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ; Fans M106 P0 S0.3 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 S1 I0 F500 H0:1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on M106 P2 S1 I0 F500 H0:1 T45 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Custom settings are not configured ; Miscellaneous M501 ; Load saved parameters from non-volatile memory -

Print wont start but states its finishedposted in Firmware installation

So I'm in the process of fine tuning my Prints and I have started making some parts for my car.

Finally get a good model happening and when I Hit the button to Upload and print. It up loads the Gcode file and then turns the hotend and bed off and tells me the prints has completed.The printer doesnt even home or try to do a preprint calibration.

I was printing 2 days ago turned it off and then came to print today and got given this.

Any ideas?

Heres my config file:

[[language]] ; Configuration file for Duet WiFi (firmware version 1.17) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool on Tue May 16 2017 21:36:43 GMT+0800 (W. Australia Standard Time) ; General preferences M111 S0 ; Debugging off G21 ; Work in millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M555 P2 ; Set firmware compatibility to look like Marlin ;Wifi Networking M552 S1 ; Enable Wifi ;*** The homed height is deliberately set too high in the following - you will adjust it during calibration. M665 L305 R150 H315 B130 X0 Y0 Z0.000 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 A0 B0 ; Put your endstop adjustments here, or let auto calibration find them M208 Z-2 S1 ; Set minimum Z ; Endstops M574 X2 Y2 Z2 S1 ; Define active high microswitches M558 P1 X0 Y0 Z0 H5 F200 T2400 ; Set Z probe type to unmodulated, the axes for which it is used and the probe + travel speeds G31 P500 X0 Y0 Z0.720 ; Set Z probe trigger value, offset and trigger height M557 R130 S20 ; Define mesh grid ; Drives M569 P0 S0 ; Drive 0 goes forwards M569 P1 S0 ; Drive 1 goes forwards M569 P2 S0 ; Drive 2 goes forwards M569 P3 S0 ; Drive 3 goes backwards M350 X16 Y16 Z16 E16 I1 ; Configure microstepping without interpolation M92 X100 Y100 Z100 E410 ; Set steps per mm M566 X1200 Y1200 Z1200 E1200 ; Set maximum instantaneous speed changes (mm/min) M203 X18000 Y18000 Z18000 E1200 ; Set maximum speeds (mm/min) M201 X1000 Y1000 Z1000 E1000 ; Set accelerations (mm/s^2) M906 X1000 Y1000 Z1000 E1200 I60 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Pressure Advance ; M572 D0 S0.25 ; Heaters M143 S285 ; Set maximum heater temperature to 285C M305 P0 T100000 B3950 C0 R4700 ; Set thermistor + ADC parameters for heater 0 M305 P1 T100000 B4388 C0 R4700 ; Set thermistor + ADC parameters for heater 1 ; Tools M563 P0 D0 H1 ; Define tool 0 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ; Network M550 PMiniKossel ; Set machine name M552 P192.168.1.14 S1 ; Enable network and set IP address M553 P255.255.255.0 ; Set netmask M554 P192.168.1.254 ; Set gateway ; Fans M106 P0 S0 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 S0 I0 F500 H-1 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P2 S1 I0 F500 H1 T45 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Custom settings are not configured ; Miscellaneous M501 ; Load saved parameters from non-volatile memoryFirmware Version: 1.18.1 (2017-04-09)

WiFi Server Version: 1.03 (ch fork)

Web Interface Version: 1.15athis is on my Custom Kossel XL.

-

RE: Kossel xl custom built. Ir sensor coding fixedposted in General Discussion

Yeah I have I think the issue is that the z height keeps ending up being to low even after recalibration and re adjustment of trigger height it still ends up squishing after to much so it creates pressure in the Bowden and also buldges on the outline layers problem is I do t know how to fix it.

-

RE: Kossel xl custom built. Ir sensor coding fixedposted in General Discussion

Yeah I have seen his channel I like his videos. Iv managed to print simple stuff now but I tend to get blobs and so own that harden to the point that it actually ends up knocking the effector off the rods well printing.

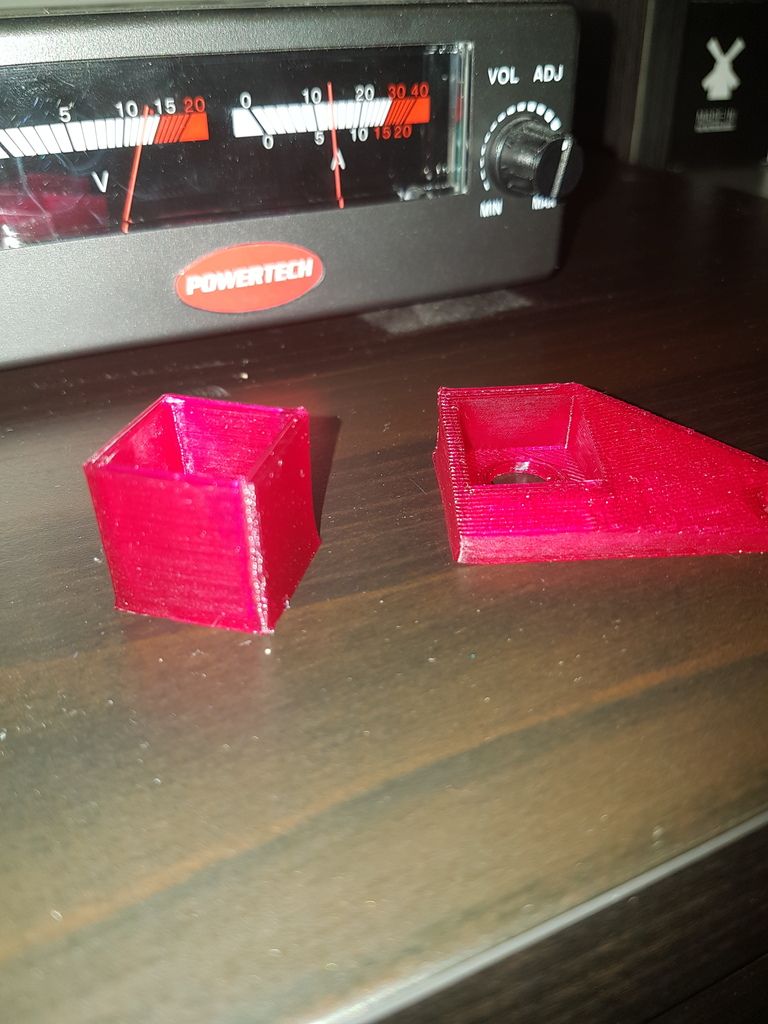

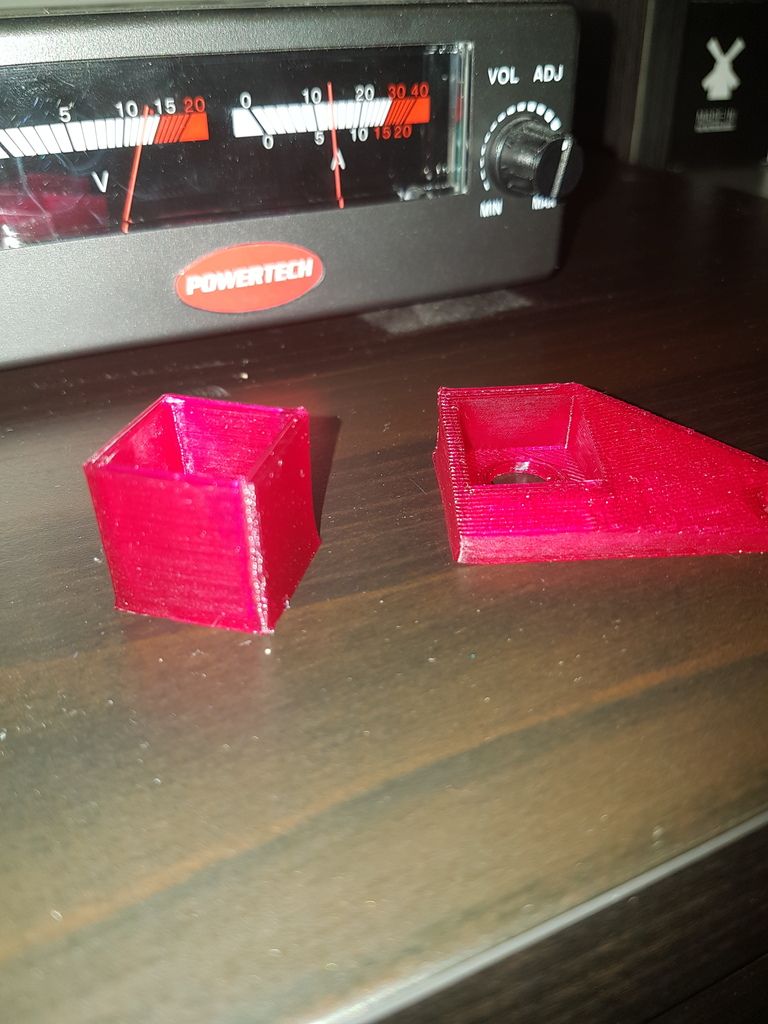

Here's what I can print with ease.

But this is the problem that's happening. Don't know if you can see it.

-

RE: Weird First layer issueposted in General Discussion

My Bowden tube is just over a metre long but I had this issue before I set up pressure advance the small cube is what I was using to calibrate the pressure advance. Burtoogle I'll remember what you said when I do print pet.

-

RE: Weird First layer issueposted in General Discussion

Hi, it looks like you are using PET which loves to glob together into little balls that then stick to the extruder and cause problems. For PET I am using 235-240 nozzle temp and 80 for the bed. If you are using Cura to slice, turn off combing as this tends to produce dribble which forms balls as mentioned above. Make sure the first layer isn't too near the bed, PET doesn't like being squished down. And don't go too fast, I am using 30mm/S for everything except infill which is 40mm/S.

Hi I'm using the colour fab violet translucent pla and using simplify3d without coasting and wiping but I have pressure advance set to 0.5

-

Weird First layer issueposted in General Discussion

So these are the prints I'm able to make with ease but as soon as I try and do anything more complicated It seems as if I'm either over extruding which I have calibrated and all seem good I have am also capable of printing the parts mentioned above.

I also thought maybe the nozzle is to close to the bed so I had adjusted my G31 z parameter lower to move the nozzle up higher but I still get this issue which seems to knock the effector off the magnetic rods.

So any idea of what's cause these random blobs every where.

-

RE: Kossel xl custom built. Ir sensor coding fixedposted in General Discussion

I think it's the z linear rail as after I do a calibration I home the printer then go to check the z height and it's set too high.

-

RE: Kossel xl custom built. Ir sensor coding fixedposted in General Discussion

I have changed my Step/mm to 100 as DjDemonD suggested.

I have a Feeling its the linear rail on Z now that you mention it when I was installing it it didn"t seem quite as smooth as the others so i washed the bearings down with brake cleaner and re-lubed them with some lithium grease rebuilt the carriage which seemed to help but i guess it wasn't enough. luckily I have some Hiwin Linear rails coming to bad they aren't black but function over form

-

RE: Kossel xl custom built. Ir sensor coding fixedposted in General Discussion

Ok I tested the trigger height 10 times now and 5 times it came up with Z1.363 and 5 times it came up with Z1.403

I was going to just test it 5 times to make sure it was consistent but on the 5th time it came up with Z1.403.

So I did one more test as piece of mind and it went back to Z1.363. then from the 7th time to the tenth time it produced Z1.403So ill use 1.403 as the trigger height since it was the last set that showed up but is this something that I should be worried about?

-

RE: Kossel xl custom built. Ir sensor coding fixedposted in General Discussion

If you still have problems when you try again, let me know which step you get stuck at. You mentioned "night and day" - are you sure that the IR sensor is giving a consistent trigger height regardless of the lighting conditions?

Yeah I followed your guide on checking for consistent triggers and it aligns to the guide. I finaly have a few hours to work on it so ill start fresh with endstop adjustments set to zero and see if it will play ball today.

Thank you David

I just want to print something haha

-

RE: Kossel xl custom built. Ir sensor coding fixedposted in General Discussion

Thank you David, I did try that last night following your guide and it didn't help but this printer seems to be like night and day, and today is a new day so I'll try again when I get home.

Thank you for the help.

-

RE: Kossel xl custom built. Ir sensor coding fixedposted in General Discussion

Ok sadly this thing has decided to act up once again. I managed to get some time to sit down and try the cube test. So I figured I'd double check my z height and do another calibration preprint.

With the paper test the height still had 40mm to go before it hit zero. So I 're adjusted the height within the config file and double checked it.

It was paper perfect, so I thought ok time to auto calibrate and it came back with a devation of before 5.002 after 1.236. Then I recalibrated untill I managed to get it down to 0.2xx I can't remember exactly. Then it climbed all the way up to 9.xxx.

I restarted the printer to get back to the 0.2xx that was saved And tested the z height and once agian it wanted to go through the bed.

I spent about an hour going back and fourth with this before I lost my temper in pure frustration I turned everything off and walked away. This is what it was doing before the rebuild but now I have no idea what to do because it feels like it just doesn't want to work.

What do you guys think is the issue?

-

RE: Kossel xl custom built. Ir sensor coding fixedposted in General Discussion

Thank you so much guys I really appreciate all the help. I'll keep this all in mind when I can finally get to do the test prints on Friday.

-

RE: Kossel xl custom built. Ir sensor coding fixedposted in General Discussion

Thank you guys so much for your help I was pretty much ready to just bin it and give up. Also the information you provided has helped full most of the black hole in my understanding of what to do next.

I'm running gt2 belt and pulleys that are 16 teeth with 1/16th stepping.

-

RE: Kossel xl custom built. Ir sensor coding fixedposted in General Discussion

As excited I as I am to do a test print I have to get ready for job number 2

-

RE: Kossel xl custom built. Ir sensor coding fixedposted in General Discussion

Now what makes it a good result? is it the deviation being as low as possible or is it to do with with the m665 results being close as possible to the M666?