Before going into detail on this project, I want to thank all those involved on this forum and elsewhere in the Duet community. Rebuilding a printer would have been a much more difficult task had it not been for the healthy, happy, and knowledgeable community on the Duet forums. Seriously, I cannot thank you folks enough.

TL;DR: Grug gut pricey printer. Make with Duet 2 wifi. Grug have happy quiet viiiirpy zoorp noises and plastic thingies made. Grug use lots of plastics with lots different letters in names now.

What this is:

I am intending to provide what I think is an interesting adaptation of an otherwise proprietary printer with open source and DIY components and software. I’m providing my observations, assumptions, and opinions derived during the original use of the printer and my journey down the road of getting it working which I started sometime in 2019.

This is probably a wee bit long winded.

What this isn’t:

I am not intending to bash, bad mouth, or harass a company or its engineers. This is not a detailed guide to modding your own printer.

Background:

Bottom line up front: The extruder is what I suspect caused the most problems, maybe the z-axis bearings and screw.

I bought a Mark One somewhat early on after relying on printers at makerspaces or owned by friends. I was attempting to avoid all the hassles of dialing in a printer and failed prints by going with the more expensive and more restrictive option of the Mk One. I wanted to prototype/make quickly and wanted to mitigate the amount of time spent on the printer itself. The company really pushed the idea that the Mark One was a simple printer to use as I had wanted. I always thought it was an apt analogy where it was compared to an apple product, and I still do. I acknowledged the risk of buying from a new company and crossed my fingers.

I encountered a series of problems the moment I unpacked the printer. Support was initially adequate but I eventually just could never get a good print or, in many cases, a completed one. I was eventually just told that I could upgrade my printer for something like $2,000 to get it to work. The printer went into disuse and was accepted as a loss.

After pulling the printer out of storage after over a long while, I started down trying to get it working again, hoping maybe a software update would help. It didn’t. I soon found out that it was no longer being supported as of June 2019 so with nothing to lose, I decided to gut it.

I am not a professional printer designer or builder by any stretch and I heavily relied on this community and others to guide me (stumbling) to a functional printer.

What some of you probably want to know first:

M669 K0 X-1:-1 Y0:-1

That's what I got to work for me. Funny enough, I couldn't get K11 ,the 'markforged' kinematics, to work.

What I changed and why

Hotend:

The hotend has a proprietary PTFE lined nozzle which was an easy choice for replacement. Being able to print nylon was a requirement for me so PTFE was a no-go… and I like my health. I went with a Slice Engineering Mosquito. Obviously, I can’t print continuous strand fiber but seeing that I couldn’t do that anyway there’s not a change there.

Mount:

Extruder:

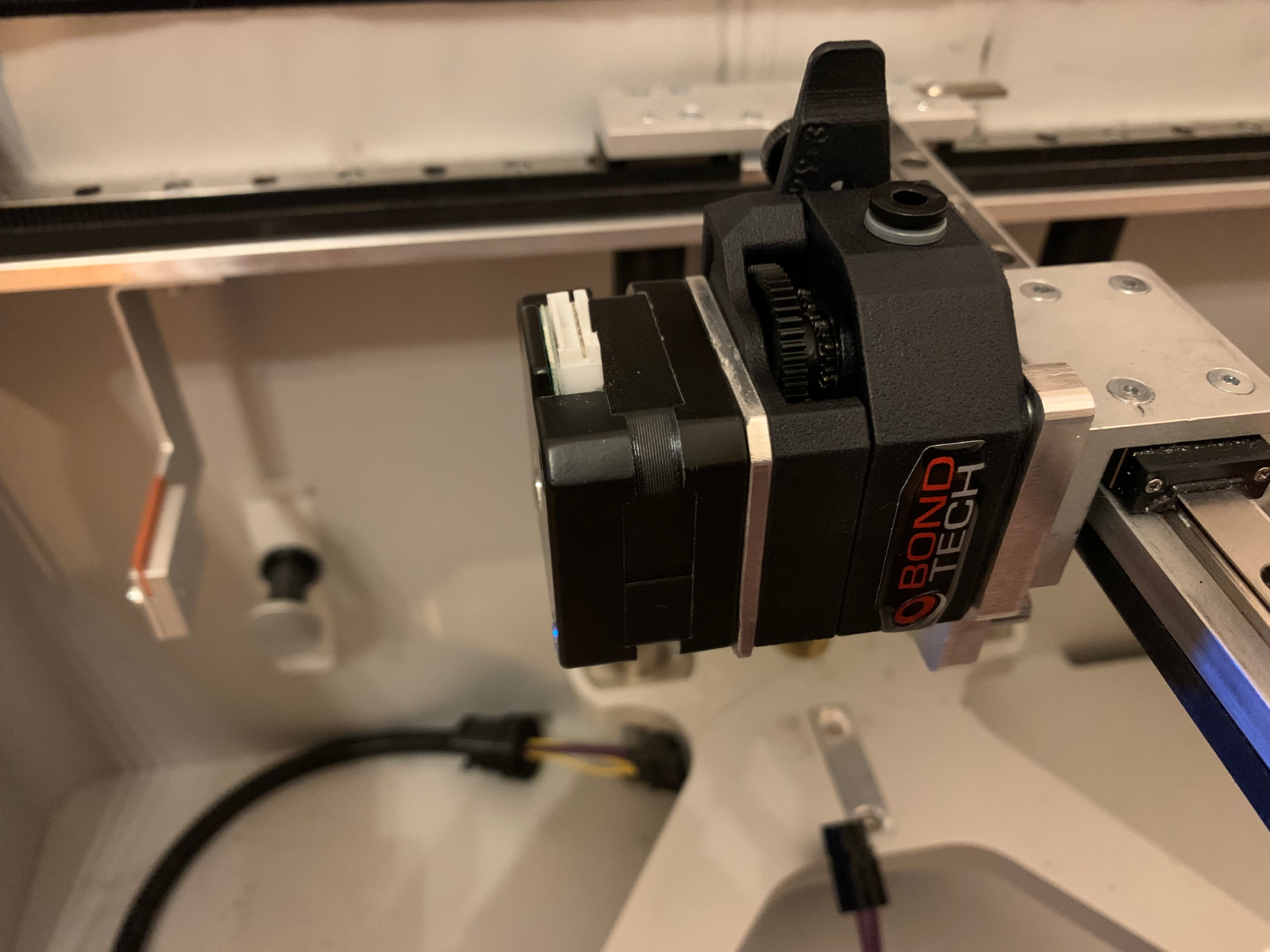

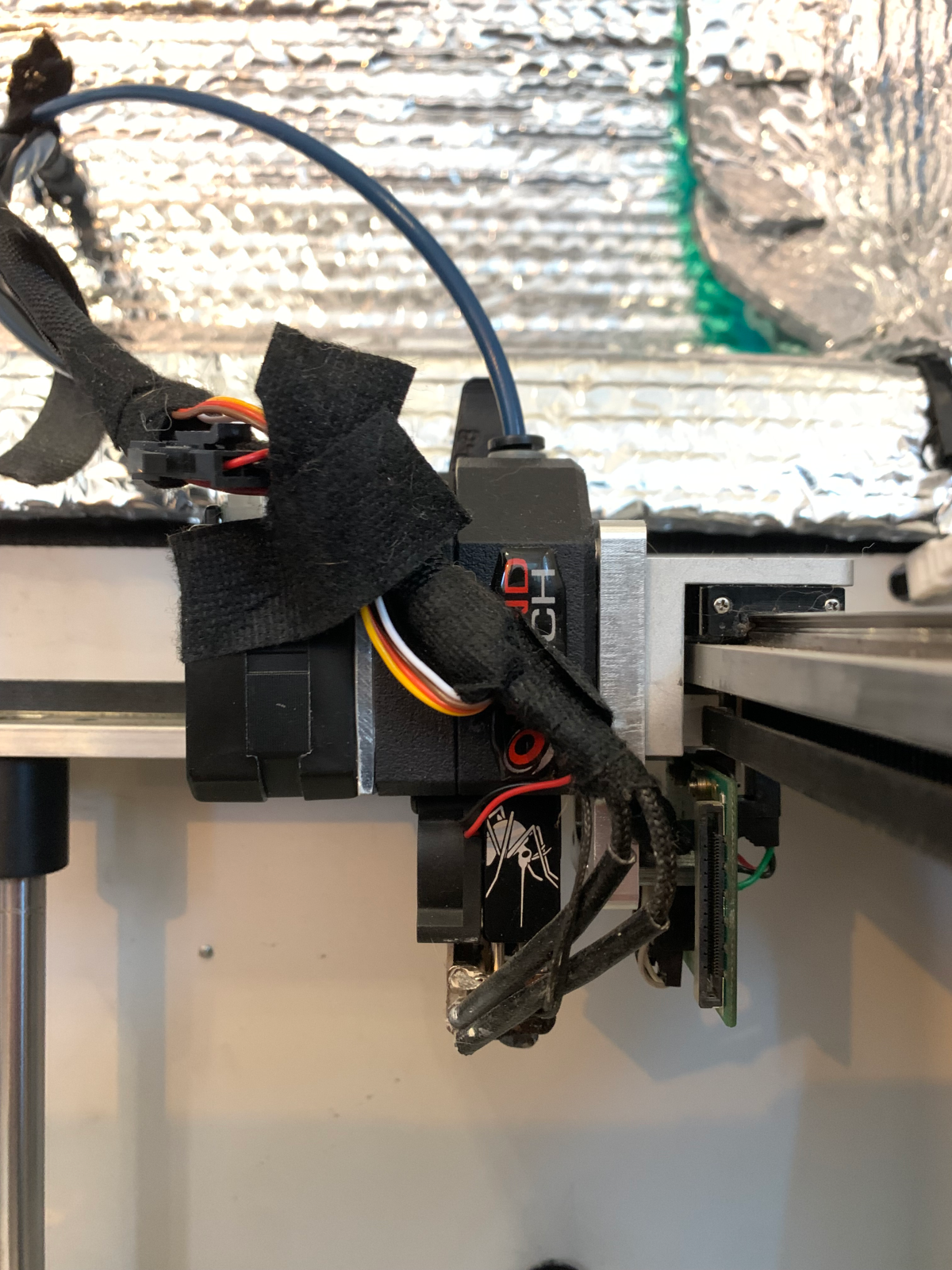

As mentioned before, I believe the factory extruder was the cause for many of my woes. Had I known what I know now, I possibly could have ID’d the problem (but why would I have bought a nearly $6,000 printer in the first place if I had my current knowledge set). I fiddled with the extruder to find that removing one of the springs would allow it to feed decently. I used it in that configuration for maybe 70 hours with consistent problems, most pointing to extrusion/retraction. I most recently machined a new mounting plate to allow me to use a Bondtech/Mosquito combo for a direct drive system, trading some X travel and weight in return.

Ugly interim/proto config:

Heated Bed:

Pretty self-explanatory, this. Having to fit a heater between the screws of the bed limited the size I could use but I’ve had a quote from Keenovo for a custom one to fit the bed perfectly. It can maintain 95 °C max after a looooooong warm up but the bed thickness helps maintain a constant heat and the temp drop off at the edges isn’t too bad. But the bed has warped a bit (not too bad) so I’m guessing it’s not cast AL like MIC6.

Current state:

I have been printing Polycarbonate, PCTG, PETG, Nylons (CF and 6-66), and currently a bunch of ASA for a Voron 2.4 (Duet 3 Mini 5+). The print quality is a TON better than the original. I have some small finalizing like cleaning up wiring and adding proper strain relief but I think it’s functional enough in its current state. I’ll probably machine a new bed out of MIC6 or just finally adapt the BL touch I have laying around. It's working, was kinda a money pit overall, but it prints now.

If you have a Mark One and you’re reading this thinking you want to do the same, may I make a suggestion? Assuming your printer is functional, it would probably be easier to use up any filament (that fits the bill) so you can and build a Voron or something.

Thanks for all the help!