To be honest, one year ago i upgraded my machine with a cheap full bmg + V6 clone as above:

By that moment, I was already using a 32b board with TMC2209 drivers (skr mini e3 v1.2), however my part 5015 blower was not properly working. I needed to manually start it at each print for it to work, otherwise it would just stay static.

By that time I was just occasionally printing pla and I had not much time to spend on it, so it stayed as it was for a while.

However I was reading about RepRap for some time and duet's interface capabilities seemed to be absolutely brilliant when compared with the ordinary marlin firmware I was using.

So I ordered a wifi board, and when I got it I tried to sort all issues that I had, but the blower was having the exact behaviour...

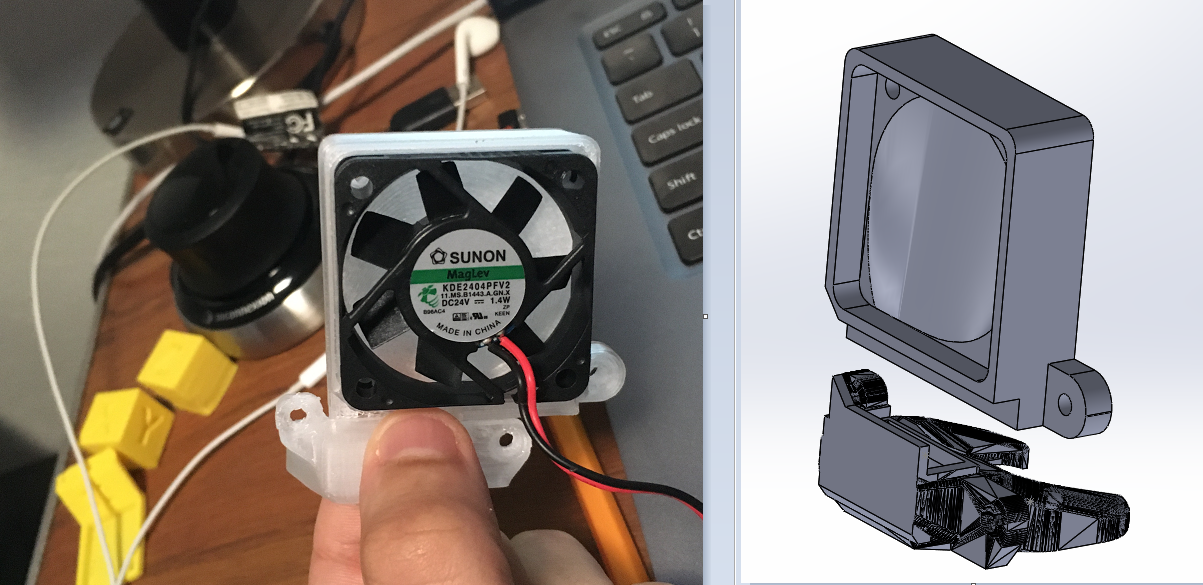

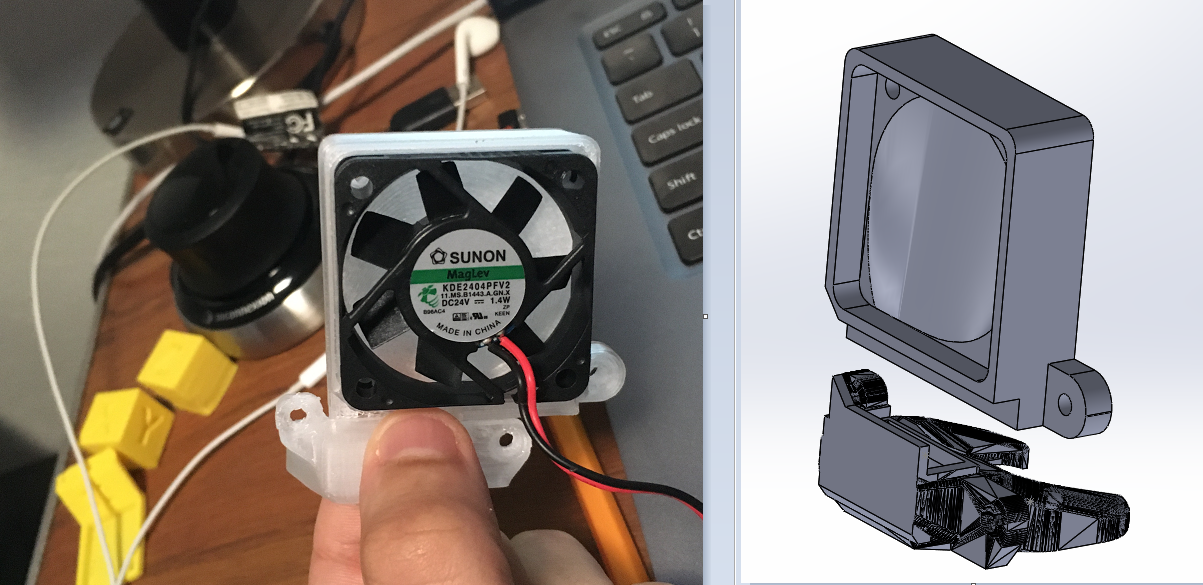

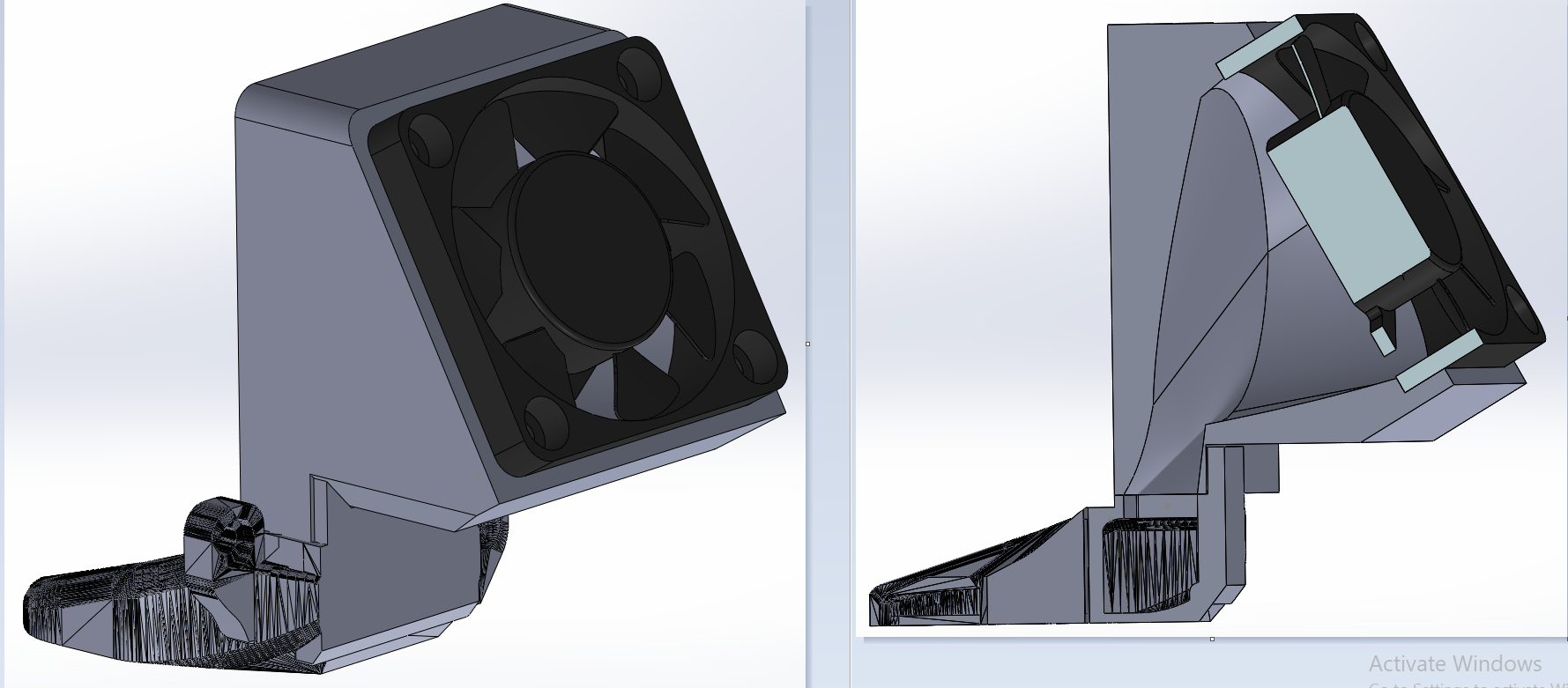

Then as I had a couple of spare sunom 4010 fans, I had a brilliant idea of design my own mod for cooling, using those fans.

So the first mod is below, and was with this that I printed both cubes and the overhang test:

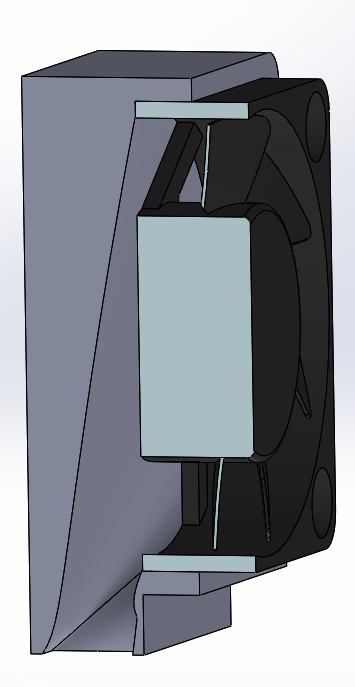

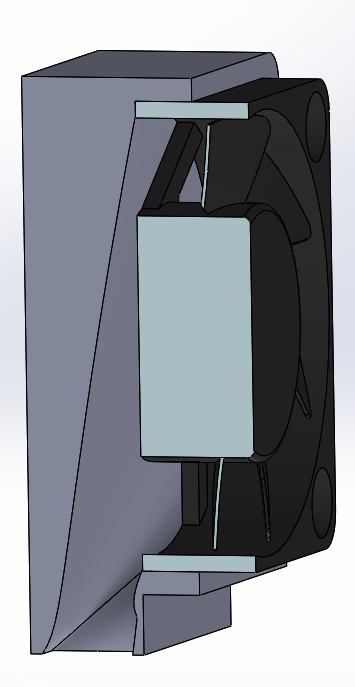

Last night after the overhang test, I realised that even being the fan working properly, the distance between the mod's interior and fan was too short and so the air flow was not moving trough the mod. It was just moving back into fan's direction.

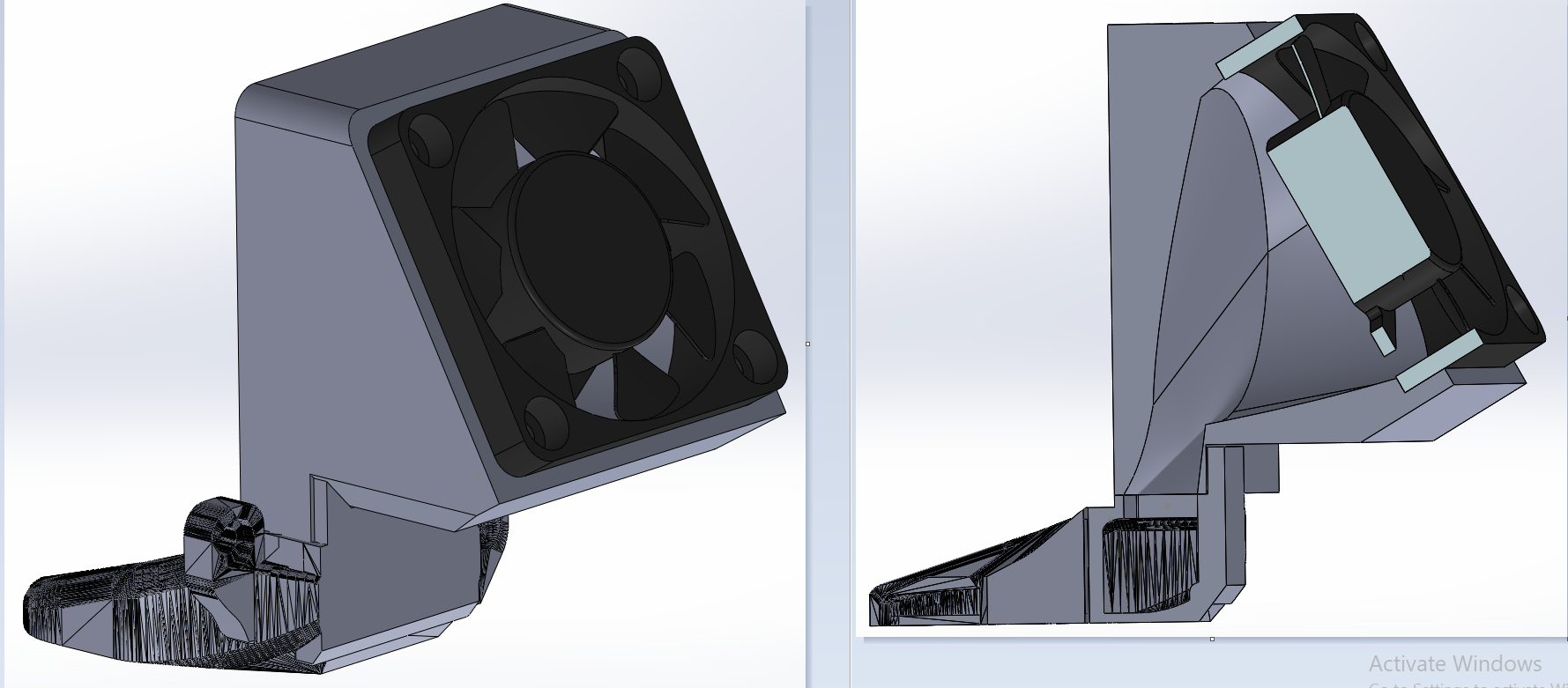

So then ok, lets improve the mod... So I gave an angle to maximise the flow direction, and I came out with this:

Now for the first time i can feel a certain blow at the nozzle... but still not what I should have yet. I am going to do a couple more calibration tests tonight and lets see what I can get from it.

However im sure that my efforts are not developing in the desired result, so if you have any tips or orientation, please expose it I will really appreciate.

Thank you for your attention and sorry about such long post! xD

![IMG_0490[1].JPG](/assets/uploads/files/1587916897093-img_0490-1-resized.jpg)

![IMG_0491[1].JPG](/assets/uploads/files/1587916938086-img_0491-1-resized.jpg)

![IMG_0485[1].JPG](/assets/uploads/files/1587757226876-img_0485-1-resized.jpg)

![IMG_0487[1].JPG](/assets/uploads/files/1587757273881-img_0487-1-resized.jpg)

![IMG_0473[1].JPG](/assets/uploads/files/1587558325430-img_0473-1-resized.jpg)

![IMG_0467[1].JPG](/assets/uploads/files/1587424804853-img_0467-1-resized.jpg)

![IMG_0458[1].JPG](/assets/uploads/files/1587222015751-img_0458-1-resized.jpg)

![IMG_0462[1].JPG](/assets/uploads/files/1587222192847-img_0462-1-resized.jpg)