I use my duet 2 wifi with a coreXY printer. Recently I've just changed from a side-by-side dual extruder setup back to a single extruder, so I updated probe offset, re-defined axis min and max limit, mesh compensation pattern, z height etc. Then something strange happened. When I tried to print a model that spans much of the Y axis range, the HE would stop moving in the Y axis hitting somewhere Y=240 but X and Z movements are normal. This means everything beyond Y=240 gets squeezed into a single line at Y=240.....I checked the gcode, no problem there as the G1 Y values go smoothly through Y=240. I then checked config.g. There's no 240 anywhere. Checked the definition of M208 and M574...nothing off there too. So, where's this 240 'invisible wall' coming from?? The only hypothesis I had was that M208 was mis-aligned with actual bed Y position. When homed, i measured the HE position and used the X, Y offset to the nearest bed corner to M208 the origin, per the tutorial on this website. I then put in 305 305 as the max value because my bed measures 310/310, to give a little margin. This apparently was not the problem.

Since I've made many changes over the past few months experimenting with mechanical tool changers, etc, the problem might be buried somewhere else in the sys folder....could somebody offer other hypotheses to try? really frustrated. thanks

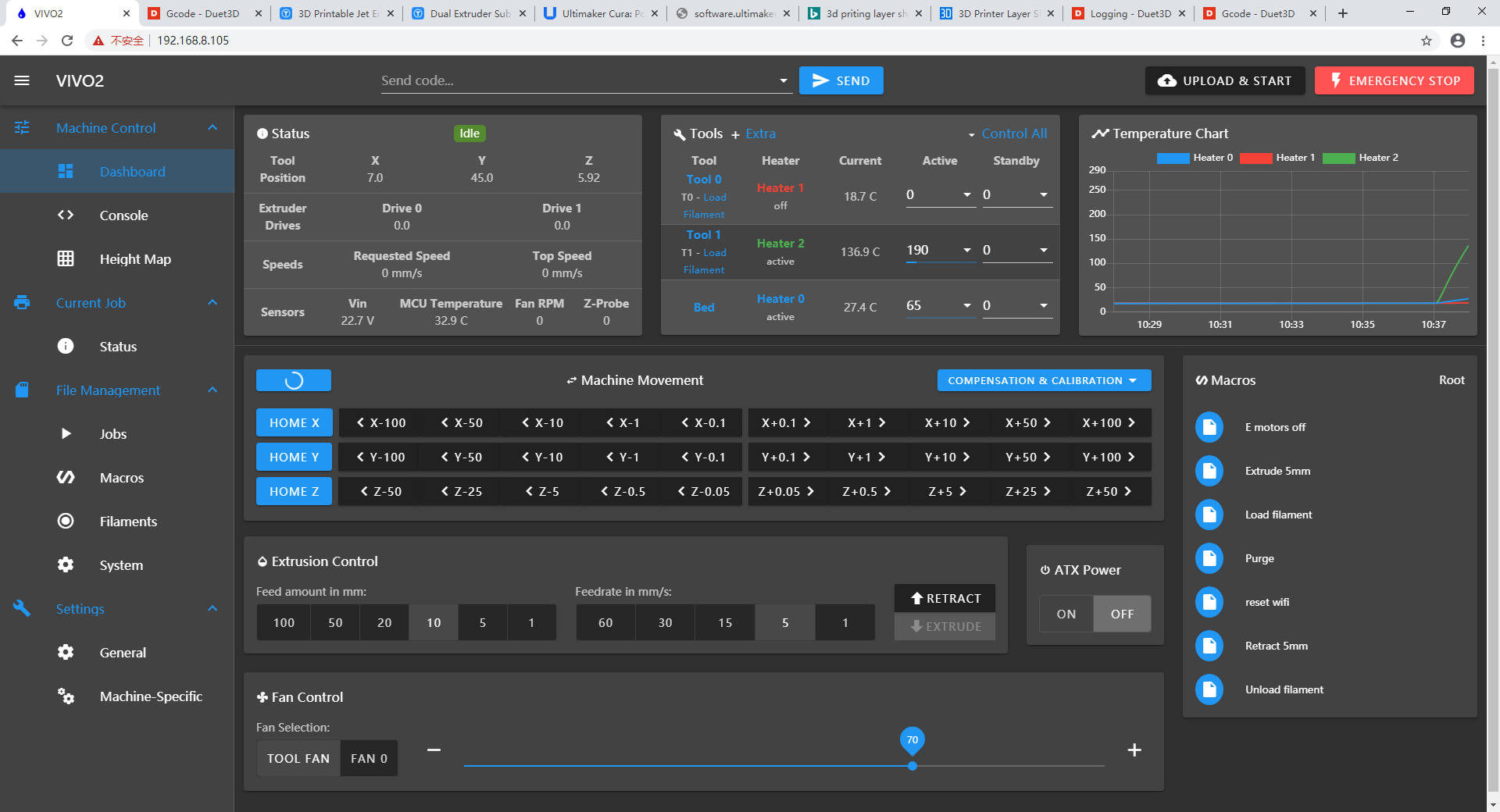

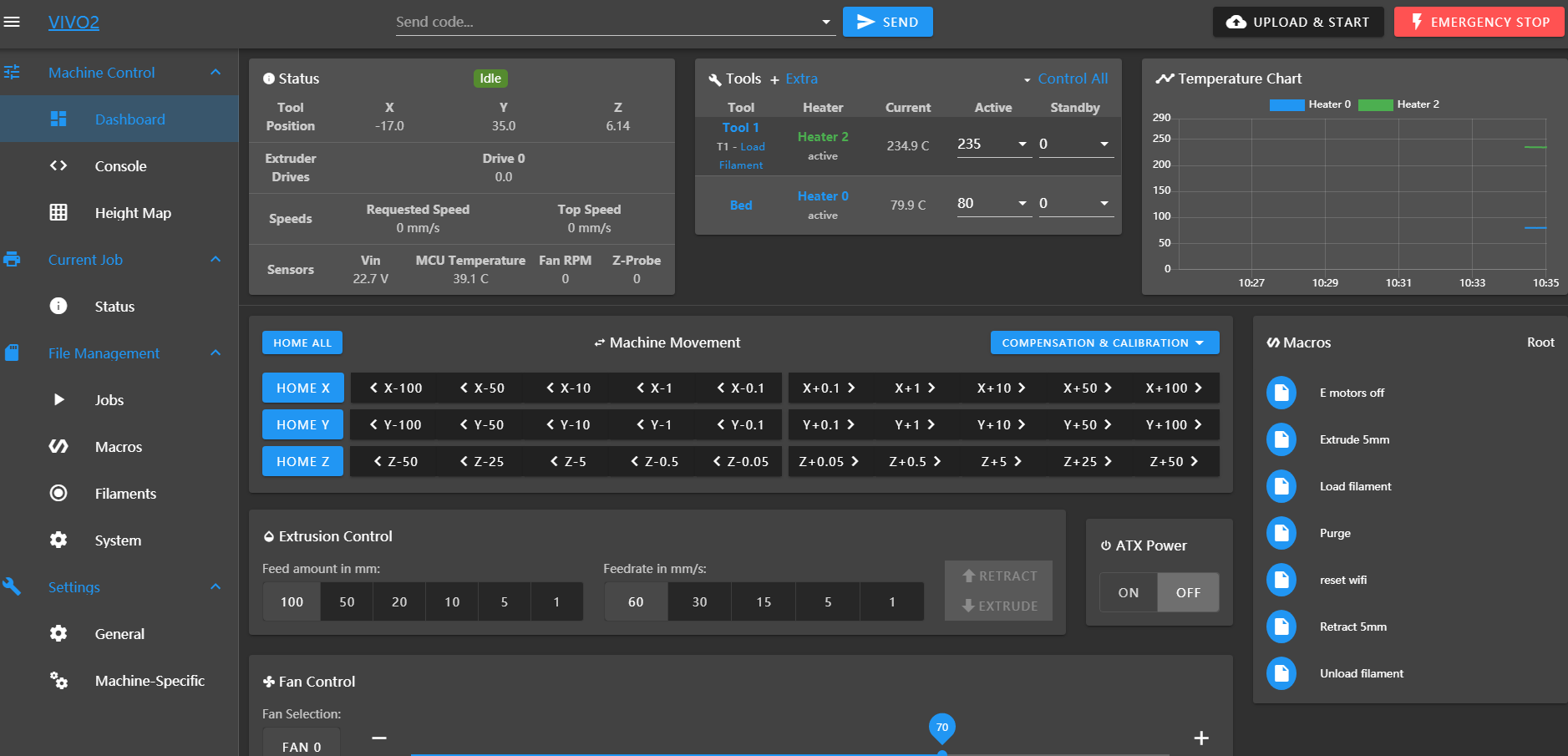

a section of my config.g:

; Axis Limits

M208 X-24 Y-7 Z0 S1 ; Set axis minima

M208 X305 Y305 Z340 S0

; Endstops

M574 Y1 S0 ; Set active low and disabled endstops

M574 X1 S1 ; Set active low and disabled endstops

; Z-Probe

M574 Z1 S2 ; Set endstops controlled by probe

M558 P5 H5 I1 F120 T6000 ; Set Z probe type to switch and the dive height + speeds

G31 P500 X20 Y-15 Z0.707 ; Set Z probe trigger value, offset and trigger height

M557 X10:280 Y10:280 S50 ; Define mesh grid

fine, too.

fine, too.