@dc42

Still struggling with this. Just can't work it out. I'm not using mesh levelling (at least I've never enabled it intentionally and I don't see anything related to it in my configs)

;Run the Z Probe at the current position

M291 P"Probing to find Z=0" S0 T2

G90 G0 Z30 ; Quick move down to Z30. (Comment this out for long drill bits)

M208 Z-10 S1 ; Temporarily allow negative movement

G30 Z-205 ; Single Z Probe. (Descend slowly untill the probe is triggered)

M208 Z0 S1 ; Dissallow negative movement

G1 H3 Z205 F360 ; Move Z up stopping at the endstop and set Z maximum to current position.

M208 Z-0.75 S1 ; Allow slight negative movement for drilling etc

This is my Z-Probe Macro which I just ran to make 0 the top of the spoils board.

In this Job I have the final contour pass set to go -0.1 to make sure it goes all the way through and skims the spoils board by a hair.

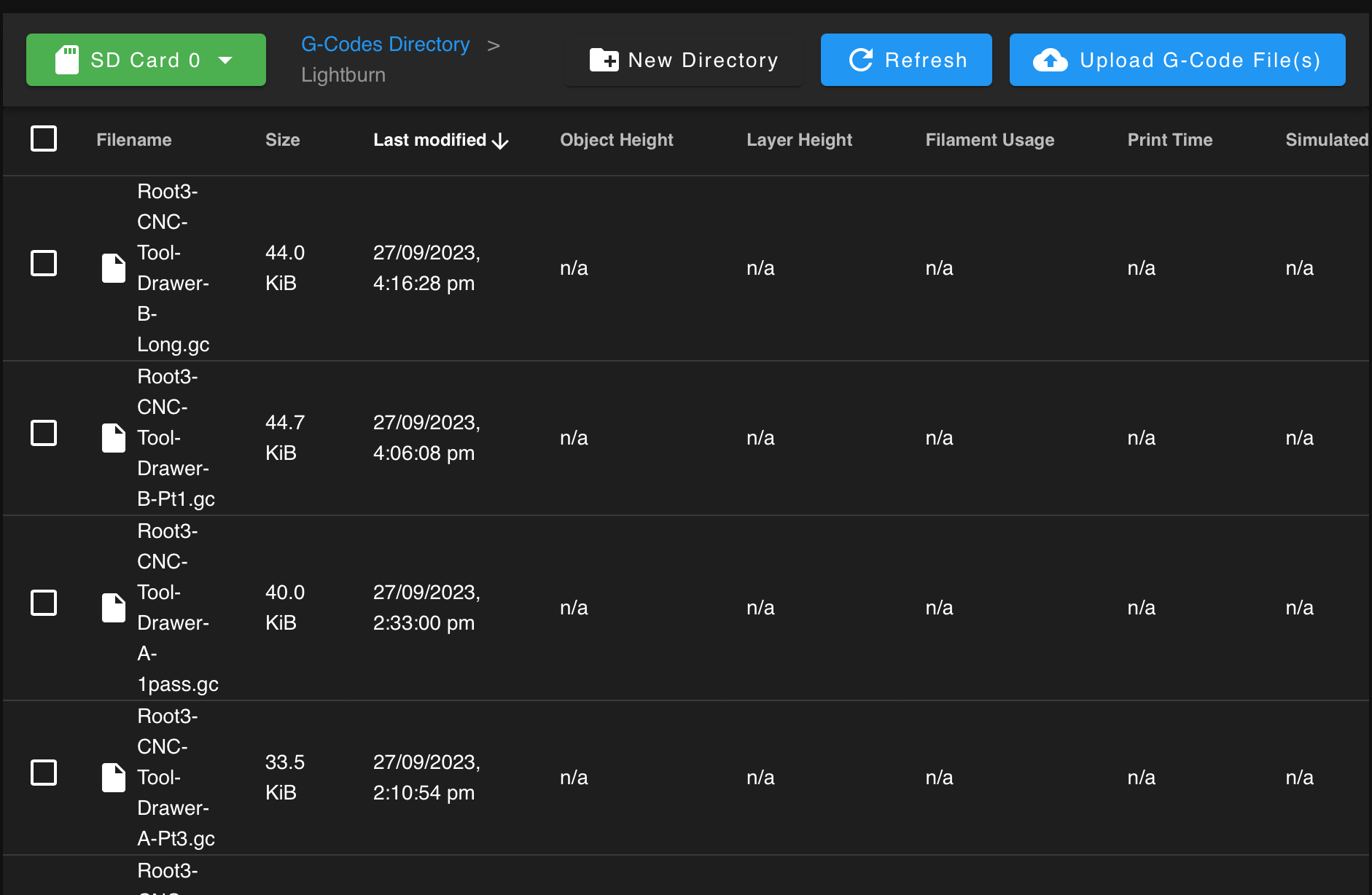

Ran the job and it quits at line 1380 with this as usual.

Error: in GCode file line 1380: G1: target position outside machine limits

1379 G1 X144.661 Y19.888

1380 G1 Z-0.1 F250

1381 G1 X144.527 Y20.25 F1920

Given that my probe macro just set Z axis minimum to -0.75, why is it triggering this error?

What common can I issue to the console to check what Z axis minimum is actually set to to check if its working?

EDIT:

Could it have something to do with Tool Change?

Even though Fusion360 free wont combine multiple tool operations into a single NC program, this operation is still technically tool 5 in the list so the post processor is including a T5 command at the beginning of this program.

Could that be wiping out my M208 minimum?

I dont see anything in the Duet or Reprap docs about whether M208 is applied per tool, or globally.

If it is per tool, how would one set it for every tool?