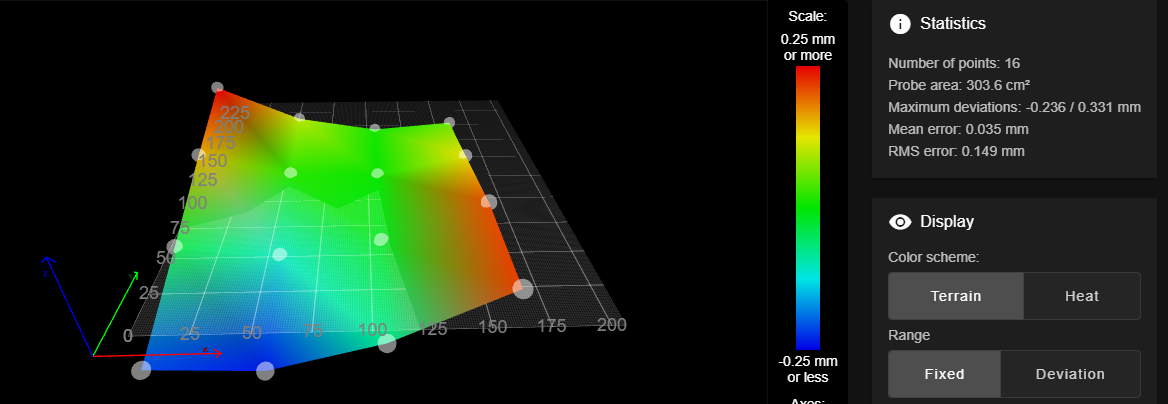

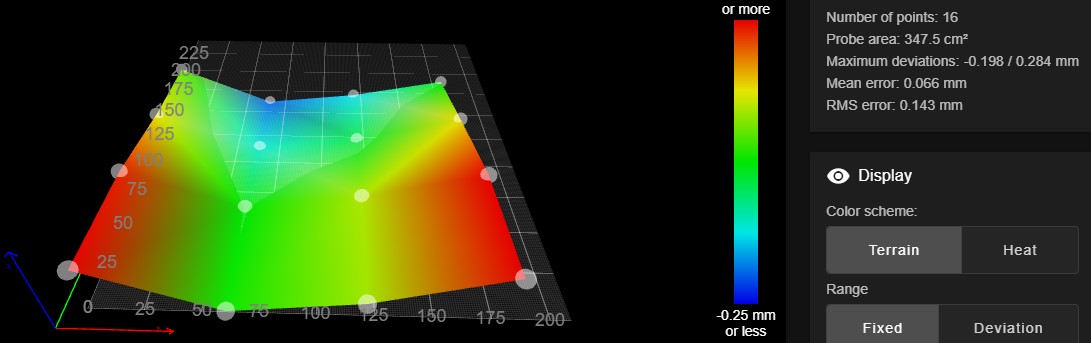

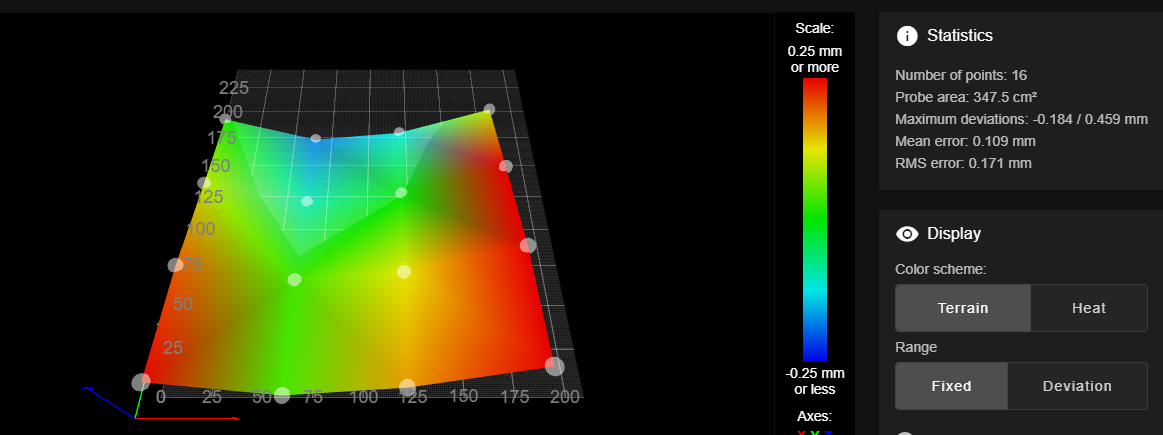

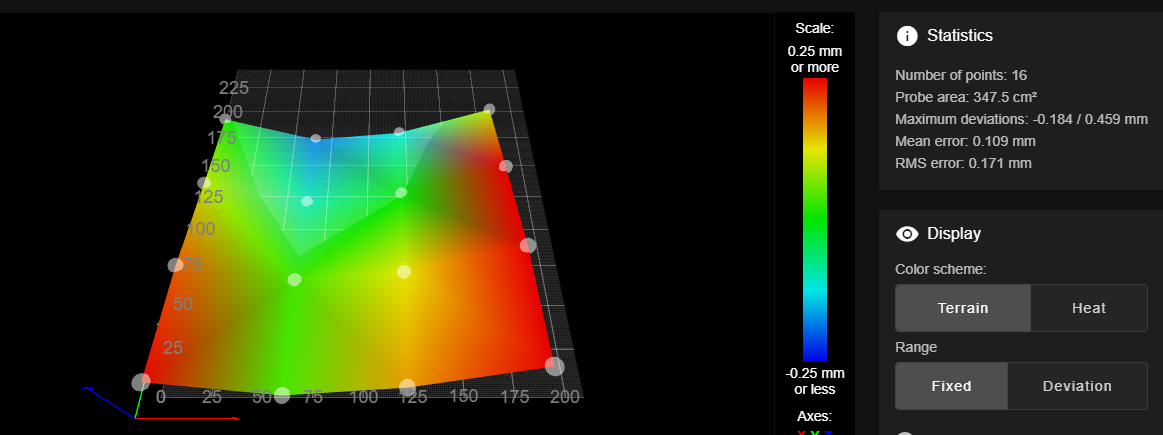

Hey guys. Finally hit wits end with this Duet board - can't get mesh bed leveling working properly no matter what I do, and it worked fine with the old Marlin control board I had in there before.

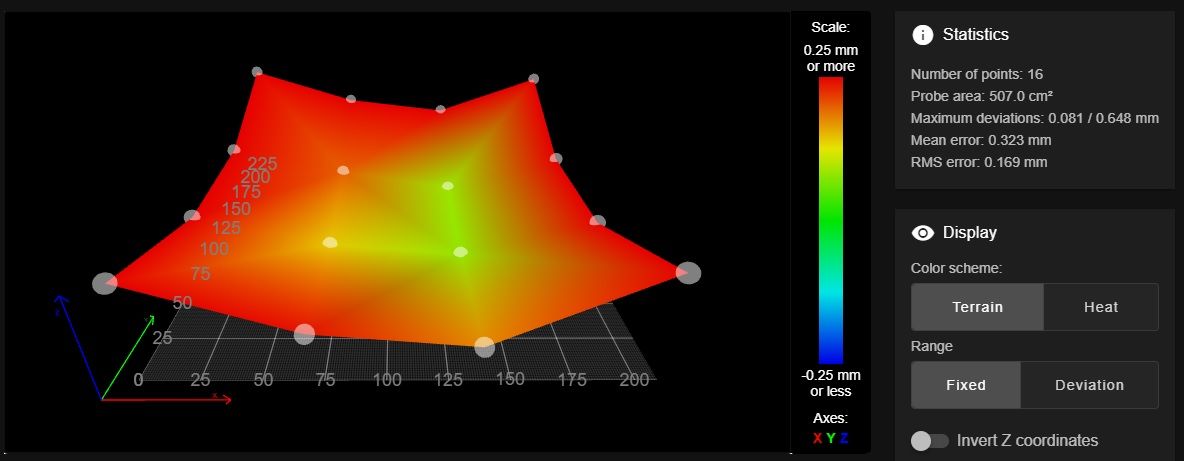

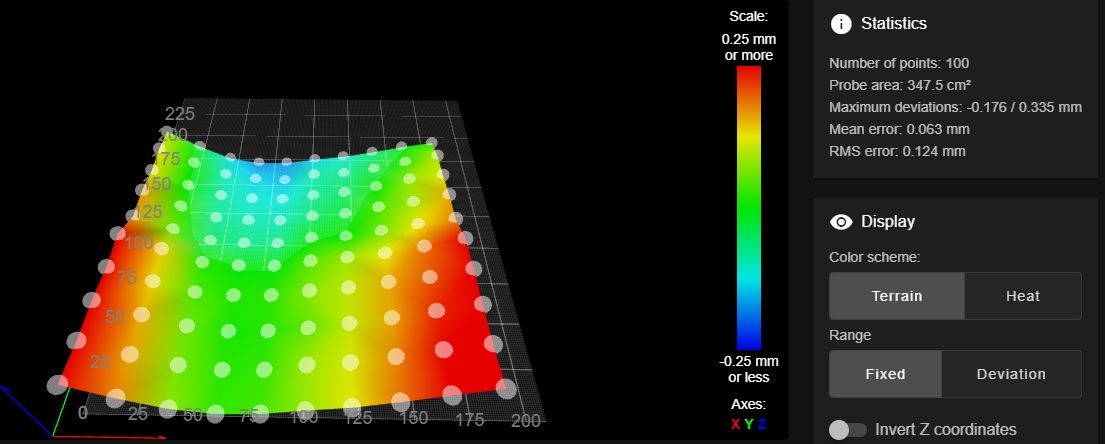

If I home the machine and load the heightmap, I can paper check the middle of the bed at Z0 and it's fine, but when the head moves left, the nozzle gets further away, opposite happening when it moves right.

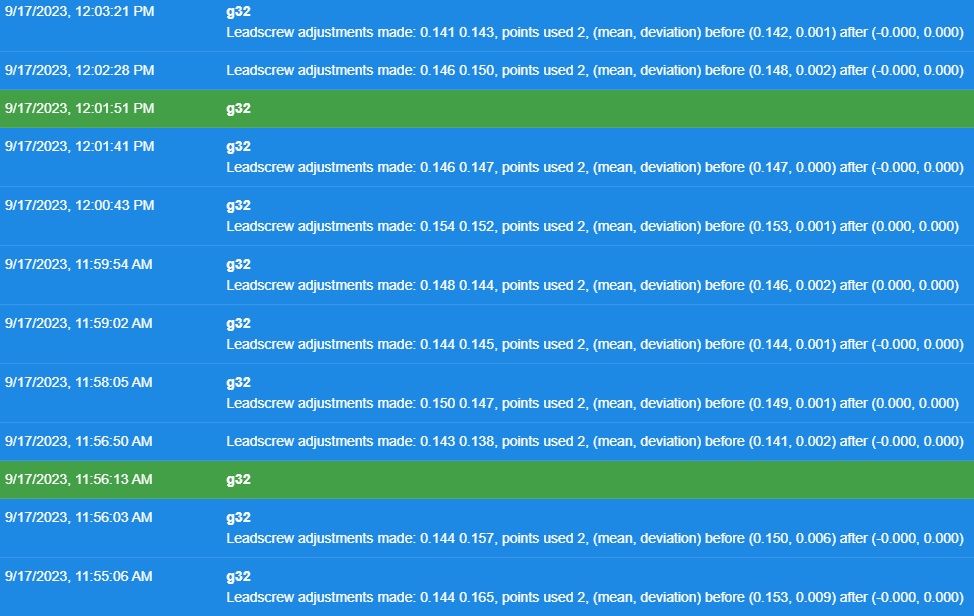

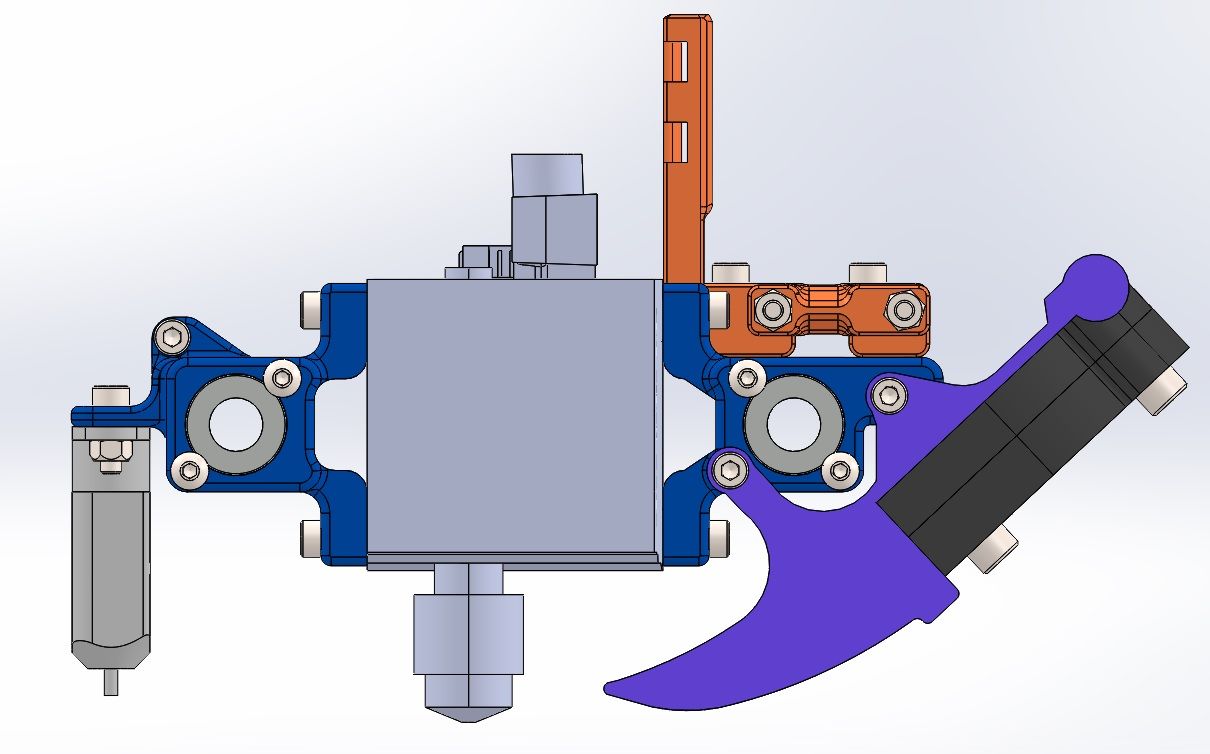

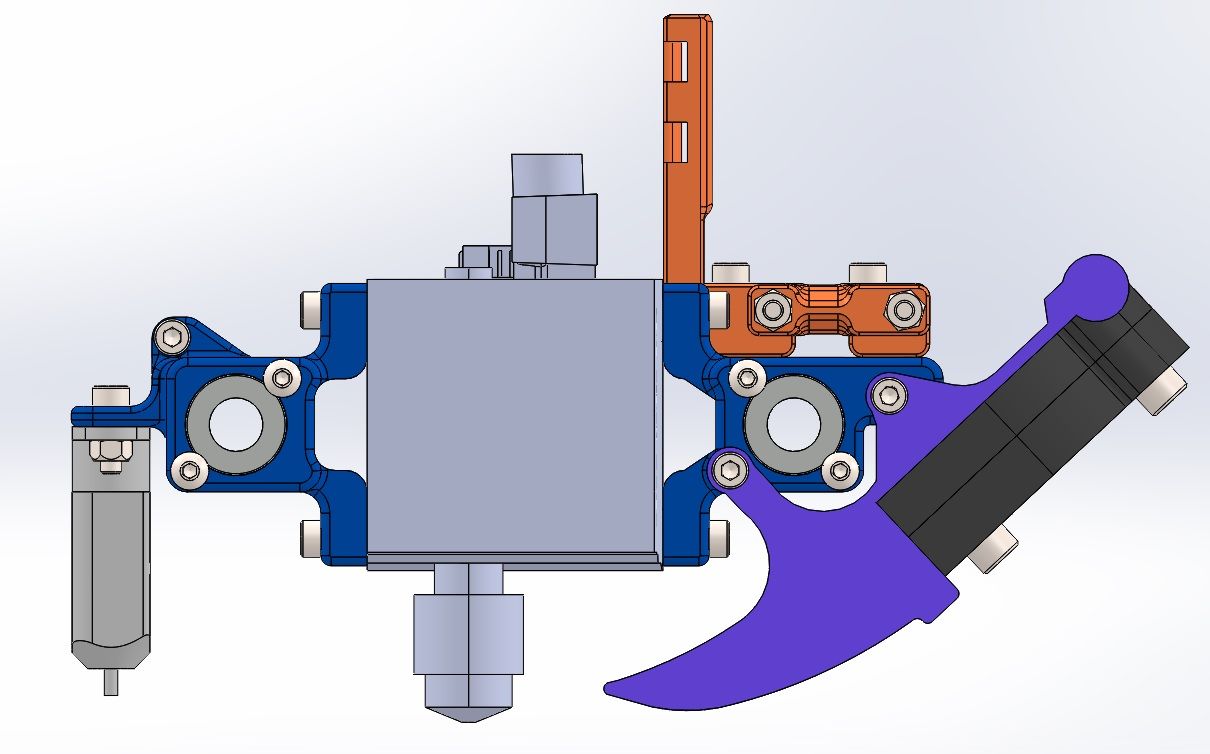

The printer is a converted Robo 3D R1+. It's a bed slinger with dual Z screws. This one has a magnetic glass bed, and the Z screws are connected to independent outputs on the Mini 5+. The head assembly is my own design using a Hemera XS and a BLTouch probe. I've got G32 working to probe each side of the bed already to level the screws.

The board is running RRF 3.4.6 stable release.

Config.g

; Configuration file for Duet 3 Mini 5+ (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.16 on Tue Aug 29 2023 17:10:44 GMT-0500 (Central Daylight Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"R1Plus" ; set printer name

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M569 P4 S0 ; physical drive 4 goes backwards

M584 X0 Y1 Z2:3 E4 ; set drive mapping

M350 X32 Y32 Z16 E16 I1 ; configure microstepping with interpolation

M92 X160.00 Y160.00 Z800.00 E397.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E300.00 ; set maximum instantaneous speed changes (mm/min)

M203 X12000.00 Y12000.00 Z1200.00 E2400.00 ; set maximum speeds (mm/min)

M201 X2000.00 Y2000.00 Z40.00 E5000.00 ; set accelerations (mm/s^2)

M906 X900 Y900 Z900 E800 I85 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

M566 P1 ; set jerk policy to 1 (default 0)

; Axis Limits

M208 X0 Y0 Z-2 S1 ; set axis minima

M208 X209 Y245 Z200 S0 ; set axis maxima

; Endstops

M574 X1 S1 P"io0.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin io0.in

M574 Y1 S1 P"io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io1.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

; Dual Z-Screw Leveling Config

M671 X0:209 Y122.5:122.5 S10 ; define z-screw pivot locations

; Filament Run-out Sensor

M591 D0 P1 C"!io2.in" S1 ; configure active low filament run-out switch for drive 0 aka E0

; Z-Probe

M950 S0 C"io3.out" ; create servo pin 0 for BLTouch

M558 P9 C"io3.in" H3 F600:60 T6000 B1 ; set Z probe type to bltouch and the dive height + speeds

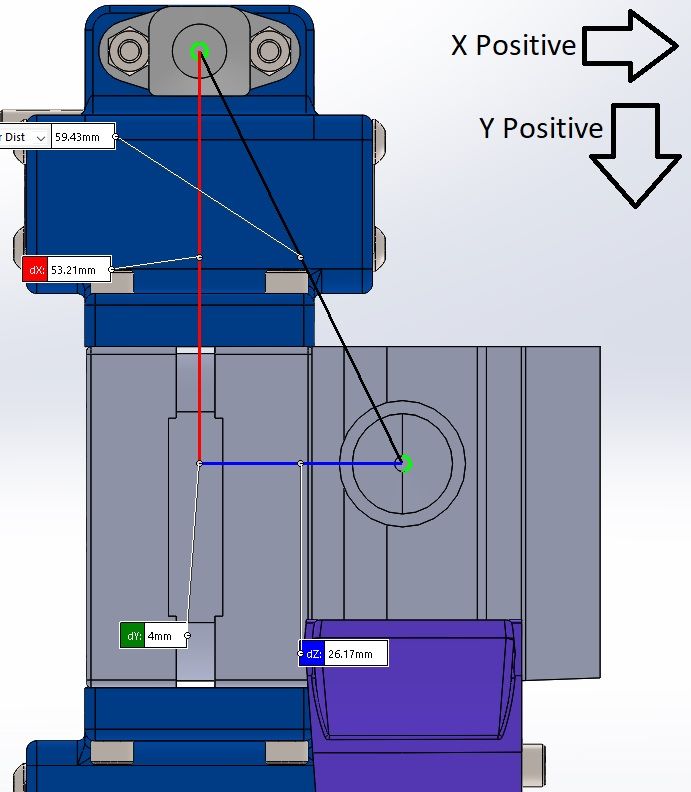

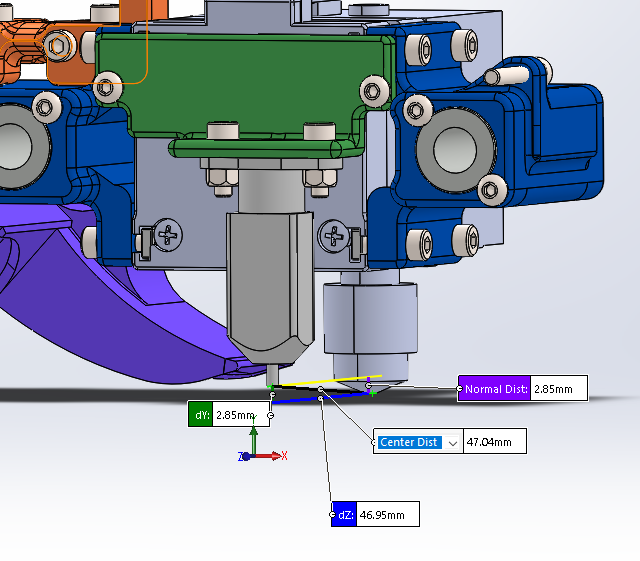

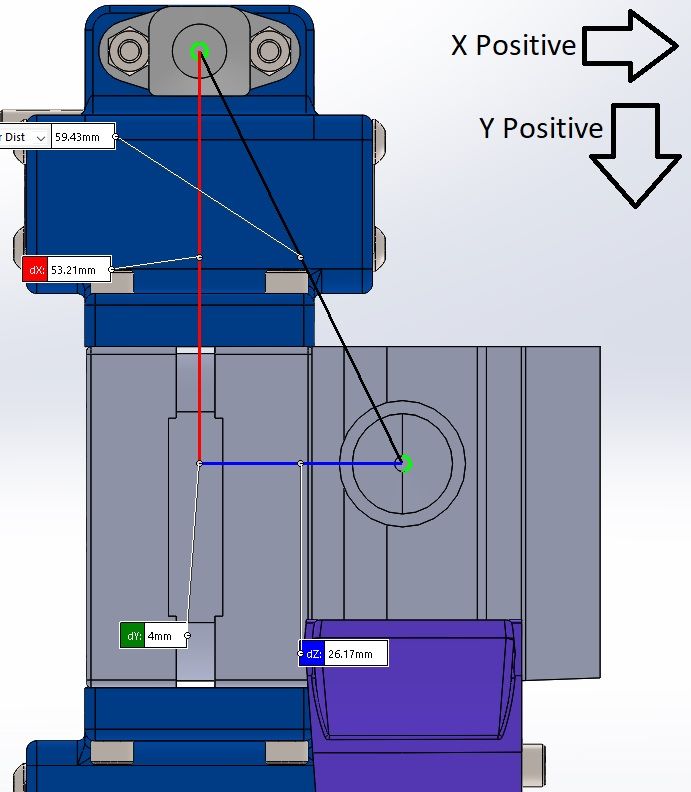

G31 P500 X-26.17 Y-53.21 Z1.45 ; set Z probe trigger value, offset and trigger height

;M557 X0:209 Y0:245 S30 ; define mesh grid - Original

;M557 X0:182 Y0:191 S45 ; define mesh grid - maxima minus probe offsets

M557 X0:182 Y0:191 P4:4 ; define mesh grid - 4x4 grid

M376 H20 ; define bed leveling taper-off height (40x Error Max)

; Heaters

M308 S0 P"temp0" Y"thermistor" T100000 B4066 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

;M307 H0 B0 S1.00 R0.30 ; disable bang-bang mode for the bed heater and set PWM limit - ORIGINAL

;M307 H1 B0 S1.00 ; disable bang-bang mode for heater E0 and set PWM limit - ORIGINAL

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"temp1" Y"thermistor" T100000 B4267 ; configure sensor 1 as thermistor on pin temp1

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M143 H1 S280 ; set temperature limit for heater 1 to 280C

M301 H0 P28.65 I2.39 D86.01 ; set bed stock PID values from original Robo3D R1+ Firmware

M307 H1 R4.371 K0.489:0.321 D2.16 E1.35 S1.00 B0 V12.3 ; set E0 PID Values

; Fans

M950 F0 C"out3" Q500 ; create fan 0 on pin out3 and set its frequency

M950 F1 C"out4" Q500 ; create fan 1 on pin out4 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on

; Tools

M563 P0 S"Revo Hemera XS" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Cabinet LED's

M950 P1 C"out5" ; enable output5 for left side LED strip

M950 P2 C"out6" ; enable output6 for right side LED strip

; Custom settings are not defined

; Miscellaneous

M564 H1 S1 ; Disallow unhomed moves & beyond axis movements

M501 ; load saved parameters from non-volatile memory

bed.g

; bed.g

; called to perform automatic bed compensation via G32

;

; generated by RepRapFirmware Configuration Tool v3.3.16 on Tue Aug 29 2023 17:10:44 GMT-0500 (Central Daylight Time)

G90 ; absolute positioning

G28 ; home

G30 P0 X0 Y122.5 Z-99999 ; probe near a leadscrew, half way along Y axis

G30 P1 X182 Y122.5 Z-99999 S2 ; probe near a leadscrew and calibrate 2 motors

G1 X104.5 Y122.5 F6000 ; go to middle of bed

G30 ; home Z by probing the bed

G90 ; absolute positioning

homeall.g

; homeall.g

; called to home all axes

;

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X-215 Y-250 F1800 ; move quickly to X and Y axis endstops and stop there (first pass)

G1 H2 X5 Y5 F6000 ; go back a few mm

G1 H1 X-215 Y-250 F360 ; move slowly to X and Y axis endstops once more (second pass)

G90 ; absolute positioning

G1 X104.5 Y122.5 F6000 ; go to middle of bed

G30 ; home Z by probing the bed

G91 ; relative positioning

G1 Z5 F6000 ; lift Z relative to current position

G90 ; absolute positioning

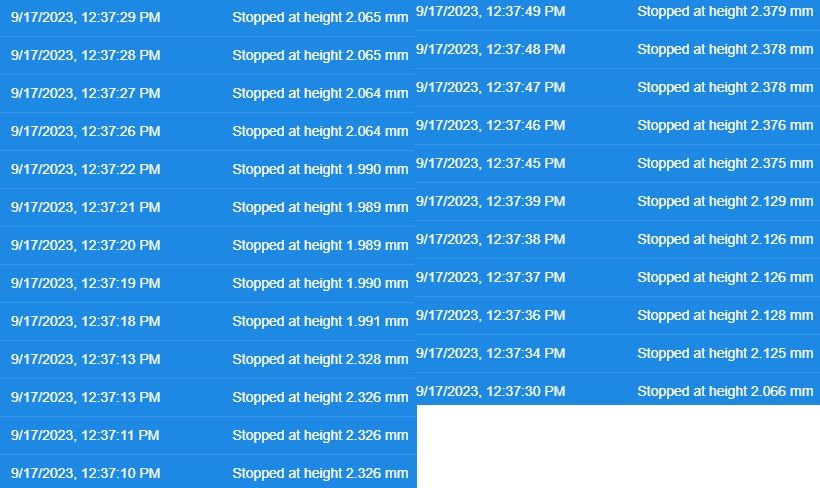

Side view of carriage.

Offset measurements.