Loud sound while extruder is retracting

-

; Configuration file for Duet WiFi (firmware version 2.03)

; executed by the firmware on start-up

;; General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder movesM669 K1 ; switch to CoreXY mode

; Network

M550 P"HYPERCUBE_EVO_NGEN" ; Set machine name

M552 S1 ; Enable network

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drives

M569 P0 S0 ; Drive 0 goes forwards (X)

M569 P1 S0 ; Drive 1 goes forwards (Y)

M569 P2 S0 ; Drive 2 goes forwards (Z)

M569 P3 S1 ; Drive 3 goes backwards (E0)

M569 P4 S0 ; Drive 4 goes forwards (E1/Z2)M584 X0 Y1 Z2:4 E3 ; Set drive mapping, two Z motors connected to driver outputs Z and E1

M671 X-25:325 Y150:150 S1.0 ; leadscrews at left (connected to Z) and right (connected to E1) of X axisM350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X80 Y80 Z400 E830 ; Set steps per mm with 1/16 and BMG extruder with 0.9° stepper

M566 X500 Y500 Z60 E360 ; jerk, Set maximum instantaneous speed changes (mm/min)

M203 X15000 Y15000 Z1000 E3000 ; Set maximum speeds (mm/min)

M201 X1000 Y1000 Z400 E2000 ; Set accelerations (mm/s^2)

M906 X1400 Y1400 Z1400 E1200 I30 ; Set motor currents (mA) and motor idle factor

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y-3 Z0 S1 ; Set axis minima

M208 X300 Y300 Z205 S0 ; Set axis maxima; Endstops

M574 X1 Y1 S1 ; Set active high and disabled endstops; Z-Probe

M574 Z1 S2 ; Set endstops controlled by probe

M307 H3 A-1 C-1 D-1 ; Disable heater 3 on PWM channel for BLTouch

M558 P9 F100 H3 R0.5 T6000 A10 S0.03 B0 ; Set Z probe type to bltouch and the dive height + speeds

G31 P25 X0 Y80 Z0.9 ; Set Z probe trigger value, offset and trigger height

M557 X0:300 Y80:300 S20 ; Set Z probe point or define probing grid; Heaters

M307 H0 A254.7 C545.2 D0.9 S1.00 V24.4 B0 ; Disable bang-bang mode for the bed heater and set PWM limit

M307 H1 A543.9 C194.7 D6.2 S1.00 V24.0 B0 ; Disable bang-bang mode for the nozzle heater and set PWM limit

M305 P0 T100000 B4725 C7.060000e-8 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M305 P1 T100000 B4725 C7.060000e-8 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S275 ; Set temperature limit for heater 1 to 275C; Fans

M106 P0 S0 I0 F500 H-1 C"HotEnd_Fan" ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 C"Extruder_Fan" ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 H100:101:102 T50:60 L0.3 C"Duet_Fan" ; set fan 2 value, turn on at 30% if the CPU temperature reaches 60C, and increase to full speed gradually as the temperature rises to 70C; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C

;M572 D0 S0.1 ; enable pressure advance; Automatic saving after power loss is not enabled

; Custom settings

M305 P101 S"DuetDriversTemp" ; temperature warning and overheat flags on the TMC2660 on Duet

M912 P0 S6.0 ; calibrate CPU temperature

M307 H2 A-1 C-1 D-1 ; Disable heater 2 on PWM channel for LED strip

M42 P2 S0 ; LED strip on heater 2 off; Miscellaneous

T0 ; Select first toolI use thermistor from e3dV6 genuine

-

thats the correct setting for the thermistor.

have you checked that there is no movement of the bowden tube during retracts?

30mm/sec retract should be fine. does the pla move through the bowden without much resistance? -

there is no movement of the bowden tube during retracts, and the pla move through the bowden without much resistance.

-

maybe 30mm/s is to much for the 0.9 degree. what current rating does the motor have? are you running 24v?

try 20mm/sec retraction speed.

-

I run at 24V 1200mA (1400mA rated).

I could try 20mm/s.

I have a full metal e3dv6 and before activate the rétractation no issue.

It's the second time I have the filament blocked in the bmg, just before the PTFE tube

-

@pipersw that picture looks quite familiar to me. In my case, the problem originated from the other end of the bowden tube: during the print, heat crept up to the cold side of the hot end, glueing the filament to the tube. Reason: extreme retraction settings in the slicer. These came unnoticed when I selected another filament type (in the slicer).

-

where is the jamming occuring? in the heatbreak?

-

@Veti In my case, multiple retractions could add-up to more than 16 mm length, pulling molten filament back up into the bowden tube, well beyond the heat break. Over time, this blocks the hot end reliably, so the extruder folds the filament as in the photo above. So, I suggest @pipersw to check the retraction settings in his slicer.

-

@infiniteloop said in Loud sound while extruder is retracting:

multiple retractions could add-up to more than 16 mm length

that would be very strange. multiple retractions without detraction should not happen.

-

@Veti Right, but with Cura, several short retractions can be "optimised" into one bigger one. Had a nice time figuring that out

-

The issue occur when I rise rétractation from 0mm to 3mm. I use a genuine full metal e3dv6, it's not recommended with pla ?

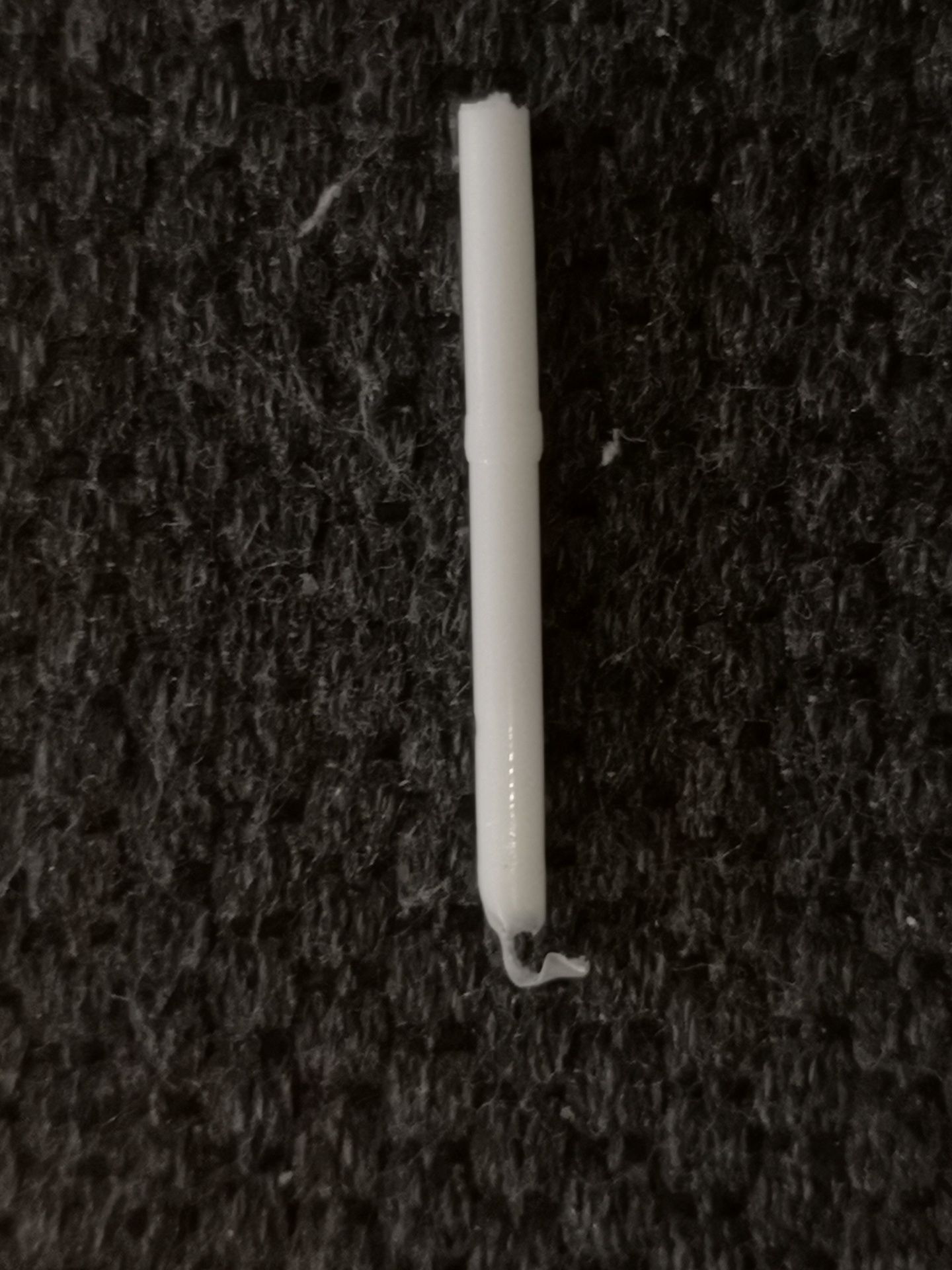

I take a picture of the filament in the heatbreak.

The diameter is 2mm on the picture, and this size is along the length of the dissipator of the e3dv6.

Before it's 1.71mm. -

@Veti yes

-

that bulge in the middle would certainly cause blocking. is there a gap between the bowden tube and the heatbrake?

that far up the plastic should not be melting. is your fan working and cooling the radiator enough? -

@Veti said in Loud sound while extruder is retracting:

that bulge in the middle would certainly cause blocking. is there a gap between the bowden tube and the heatbrake?

that far up the plastic should not be melting. is your fan working and cooling the radiator enough?Perhaps there is a gap, the bulge is 2.2mm and the fan is genuine, I have not checked the temperature

-

@pipersw said

I take a picture of the filament in the heatbreak.

@pipersw Very good picture. And yes, the e3dv6 is fine. As @Veti said, the bulge is the problem. Did you secure the bowden tube so that it can’t move under pressure? Maybe you should replace the tube, it might be worn-out after you have unmounted it several times.

However, a retraction setting of 2-3 mm should not cause the problem. Your photo hints into another direction: possibly, the tip of the nozzle is too cold? Depending on your PLA, 210 deg. should be fine, but what about the part-cooling fan if it’s cooling the nozzle instead of the filament?

After you are sure about the proper fit of the bowden tube, you should try to print without using the part cooling fan. If that doesn’t lead to a smooth extrusion, experiment with temperatures between 190 and 220 deg.

If all this doesn’t help, reduce the print speed in the slicer to 20-40 mm if you haven’t done so already. Good luck.

-

This post is deleted! -

@infiniteloop I have shorten the bowden, and I have some test in two day.

-

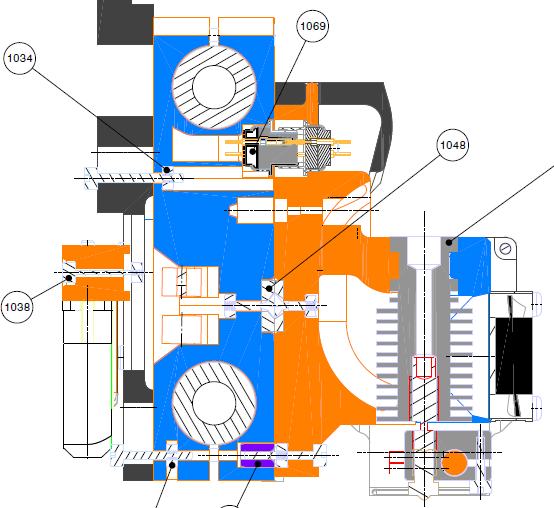

where can the air that the middle fan is blowing in escape to? to me it looks like the fans on the side may be blocking the air from escaping

-

@Veti said in Loud sound while extruder is retracting:

where can the air that the middle fan is blowing in escape to? to me it looks like the fans on the side may be blocking the air from escaping

There is a cooling path at the back (Hypercube Evo NGEN on Thingiverse)

-

@pipersw said in Loud sound while extruder is retracting:

I have shorten the bowden, and I have some test in two day.

@pipersw With such a short bowden tube, a retraction of 1-2 mm should be sufficient. I see that you use a silicon sock, this will prevent the tip of the nozzle from cooling down too much. However, when testing, it’s always a good idea to keep the number of variables low, so run your part cooling fans at low speed or turn them off.

Looking again at your filament fragment from the hot end, the question is what factor produces the bulge in the middle of it. Clearly, the bowden tube must be neatly fixed so that the visible gap will not emerge any more. Then, two theories remain: either, the hot end temperature is too low, building up pressure from below - or, heat is creeping up towards the cold side of your hot end.

This is what @Veti is looking at. Longe retractions contribute to that effect as well as a hot end driven too high (thus melting too much of the PLA) or a heated chamber (which reduces the effect of your tool cooling fan). Oh, and did you apply heat-conductive paste to the heat brake prior to inserting it into the heat sink?

The other case, under-heating, is less likely, you can rule this out with a print at about 220 deg. or so. Anyway, I’m curious about the results from your test runs. Bonne chance!