Loud sound while extruder is retracting

-

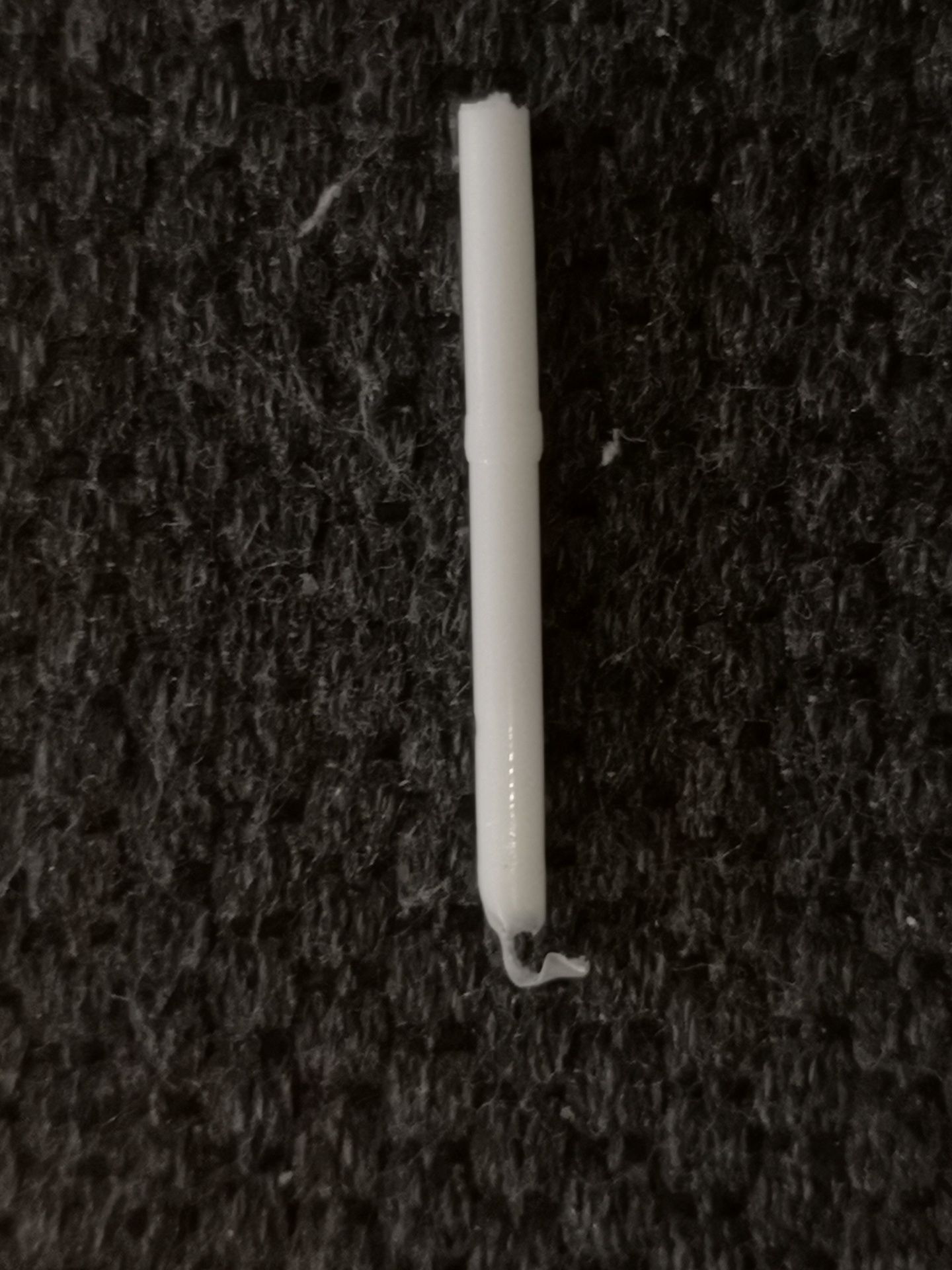

@Veti In my case, multiple retractions could add-up to more than 16 mm length, pulling molten filament back up into the bowden tube, well beyond the heat break. Over time, this blocks the hot end reliably, so the extruder folds the filament as in the photo above. So, I suggest @pipersw to check the retraction settings in his slicer.

-

@infiniteloop said in Loud sound while extruder is retracting:

multiple retractions could add-up to more than 16 mm length

that would be very strange. multiple retractions without detraction should not happen.

-

@Veti Right, but with Cura, several short retractions can be "optimised" into one bigger one. Had a nice time figuring that out

-

The issue occur when I rise rétractation from 0mm to 3mm. I use a genuine full metal e3dv6, it's not recommended with pla ?

I take a picture of the filament in the heatbreak.

The diameter is 2mm on the picture, and this size is along the length of the dissipator of the e3dv6.

Before it's 1.71mm. -

@Veti yes

-

that bulge in the middle would certainly cause blocking. is there a gap between the bowden tube and the heatbrake?

that far up the plastic should not be melting. is your fan working and cooling the radiator enough? -

@Veti said in Loud sound while extruder is retracting:

that bulge in the middle would certainly cause blocking. is there a gap between the bowden tube and the heatbrake?

that far up the plastic should not be melting. is your fan working and cooling the radiator enough?Perhaps there is a gap, the bulge is 2.2mm and the fan is genuine, I have not checked the temperature

-

@pipersw said

I take a picture of the filament in the heatbreak.

@pipersw Very good picture. And yes, the e3dv6 is fine. As @Veti said, the bulge is the problem. Did you secure the bowden tube so that it can’t move under pressure? Maybe you should replace the tube, it might be worn-out after you have unmounted it several times.

However, a retraction setting of 2-3 mm should not cause the problem. Your photo hints into another direction: possibly, the tip of the nozzle is too cold? Depending on your PLA, 210 deg. should be fine, but what about the part-cooling fan if it’s cooling the nozzle instead of the filament?

After you are sure about the proper fit of the bowden tube, you should try to print without using the part cooling fan. If that doesn’t lead to a smooth extrusion, experiment with temperatures between 190 and 220 deg.

If all this doesn’t help, reduce the print speed in the slicer to 20-40 mm if you haven’t done so already. Good luck.

-

This post is deleted! -

@infiniteloop I have shorten the bowden, and I have some test in two day.

-

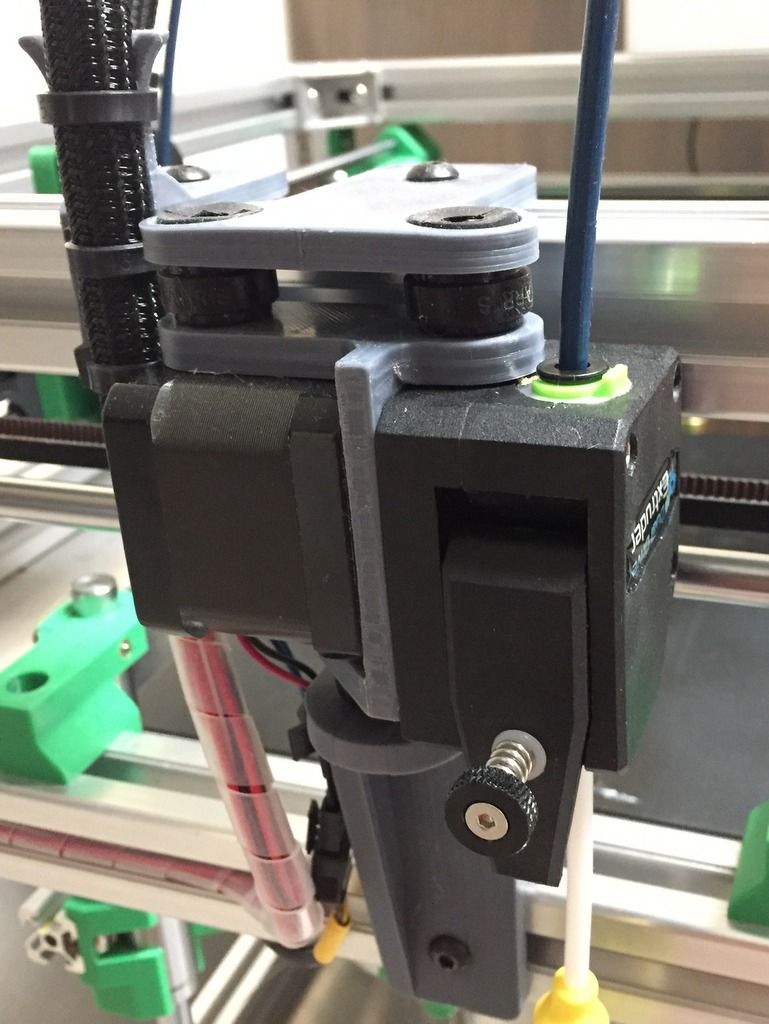

where can the air that the middle fan is blowing in escape to? to me it looks like the fans on the side may be blocking the air from escaping

-

@Veti said in Loud sound while extruder is retracting:

where can the air that the middle fan is blowing in escape to? to me it looks like the fans on the side may be blocking the air from escaping

There is a cooling path at the back (Hypercube Evo NGEN on Thingiverse)

-

@pipersw said in Loud sound while extruder is retracting:

I have shorten the bowden, and I have some test in two day.

@pipersw With such a short bowden tube, a retraction of 1-2 mm should be sufficient. I see that you use a silicon sock, this will prevent the tip of the nozzle from cooling down too much. However, when testing, it’s always a good idea to keep the number of variables low, so run your part cooling fans at low speed or turn them off.

Looking again at your filament fragment from the hot end, the question is what factor produces the bulge in the middle of it. Clearly, the bowden tube must be neatly fixed so that the visible gap will not emerge any more. Then, two theories remain: either, the hot end temperature is too low, building up pressure from below - or, heat is creeping up towards the cold side of your hot end.

This is what @Veti is looking at. Longe retractions contribute to that effect as well as a hot end driven too high (thus melting too much of the PLA) or a heated chamber (which reduces the effect of your tool cooling fan). Oh, and did you apply heat-conductive paste to the heat brake prior to inserting it into the heat sink?

The other case, under-heating, is less likely, you can rule this out with a print at about 220 deg. or so. Anyway, I’m curious about the results from your test runs. Bonne chance!

-

I have found issues. The PTFE tube not fully pushed inside the extruder and the hotend.

Filament crossing in the spool too.

Seems to work now, with 3mm retractation and 60mm/s retractation speed.600 for X and Y jerk (M566) are not too high for a core xy ?

The printer is noisy during movement changes.I have the following settingd :

M566 X500 Y500 Z60 E360

M203 X15000 Y15000 Z1000 E3000

M201 X1000 Y1000 Z400 E2000

M906 X1400 Y1400 Z1400 E1200 I30 -

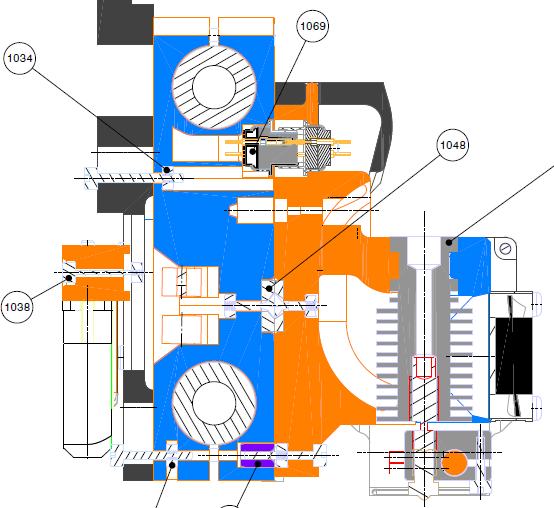

I have similar configuration to yours (bowden, 24V, 0.9deg, 3:1 gear) and had similar problems of noise. Initially I placed the stepper on suspension which stops the noise but then realized that my max extruder speed was set too high it can handle at most E1500 to E2000.

You can read more about it here

https://forum.duet3d.com/topic/12049/building-a-diy-public-domain-low-cost-stepper-motor-analyzer/2

Edit: this is the suspended extruder. It prevents the any extruder noise to be amplified by the aluminum frame. The three rubber parts are standard RC parts.