Mesh calibration not working or what am I doing wrong?

-

Hi,

Well at least the section seems pretty smooth even if badly tilted.

There are things you may be doing at the start of the print that are disabling mesh compensation.

Does the DWC interface show that mesh compensation is on? You can verify this during a print.

Frederick

-

@Dep Looking at the last two height maps you published, just one corner matches the plane which the firmware assumes to be the bed’s surface. Interestingly, the height map itself is quite consistent, i.e. relatively flat. It is just not in sync with the bed level. In order to cure this, you really should carefully level your bed and then calibrate Z=0 at its center, before you run another mesh grid calibration. As long as the resulting height map is not (at least partially) in sync with the assumed bed plane, it’s useless.

-

@fcwilt Yes, compensation is on. I checked the M122 command, and also it is visible since the bed moves up / down when printing.

-

@infiniteloop What do you mean by synchronizing with the bed?

If you mean the transition through zero, then it is when the bed is heated.

I can’t level the bed better, it is very big and heavy. And when I heat it to 120 degrees - it distorts it a lot.

Also, when the entire chamber is heated to 45 - 50 degrees, the entire system also bends.

But I do this: I warm up the bed and chamber , wait 1-2 hours and run mesh calibration two times and compare the resulting grid. If everything is ok, I'm trying to print. This is a very long process

But every time the same thing.

I don’t understand why mesh cannot perform compensation.

-

@Dep, maybe I can put it in slightly different words that might make more sense.

Suppose you have 50 mm between probing points. Also suppose you are printing a part that is 50 mm long and starts on probing point one and goes to probing point two.

The mesh compensation interprets the area between point one and point two as a straight line so let's suppose point one is at 0.1 mm and point two is 0.5 mm for the offset. This means that the Duet thinks that the height at 25 mm is 0.3 mm.

The problem is that this is a guess. With a very uneven bed, your actual offset in the middle might be -0.1 or + 1.0 or whatever. The controller does not and can not know about what is actually happening in an area that was not probed and has to make an educated guess. If that guess does not reflect the true shape of the actual bed then you get a strange print.Another way of looking at it is the mesh bed levelling can only work reasonably well if the bed does not vary wildly between probing points. It can compensate nicely if you have sufficient probing points so that the height between two adjacent probing points does not vary by a lot and the interpolation that happens between the two points can reasonably be described as a relatively straight line.

Hope that helps ....

Edit: If you were printing a model that is 50 mm * 50 mm and if you used all 121 available probe points for that small printing area, you would likely get a very nice first layer.

-

@jens55 I agree in theory with what you say but from what I can gather, @Dep has a sheet of 4mm glass on top of "something" - presumably an aluminium heat spreader of some sort. In which case, I'd have thought that it's very unlikely that there are any significant peaks and troughs between any two 50mm probe points and the glass would have a fairly even curvature. In which case, interpolation between points should be reasonably accurate.

-

I agree with you that the smaller the distance between the points, the better the calibration.

But the glass on the table cannot be bent strongly at a distance of 50mm.

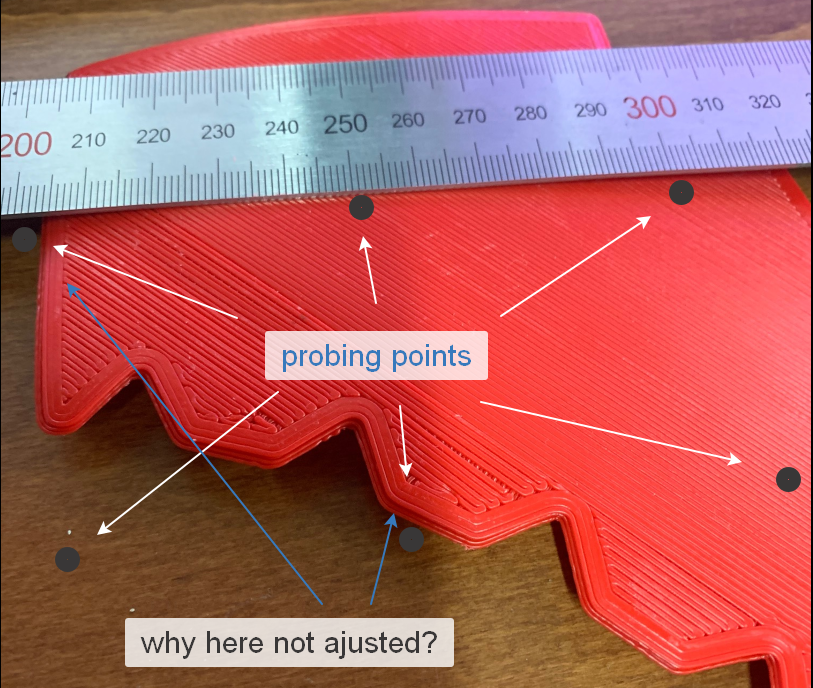

Look at the photo: why the calibration is not performed?

-

Would you post some photos of your printer and the whole config.g file?

-

I warm up the bed and chamber , wait 1-2 hours and run mesh calibration two times and compare the resulting grid. If everything is ok, I'm trying to print.

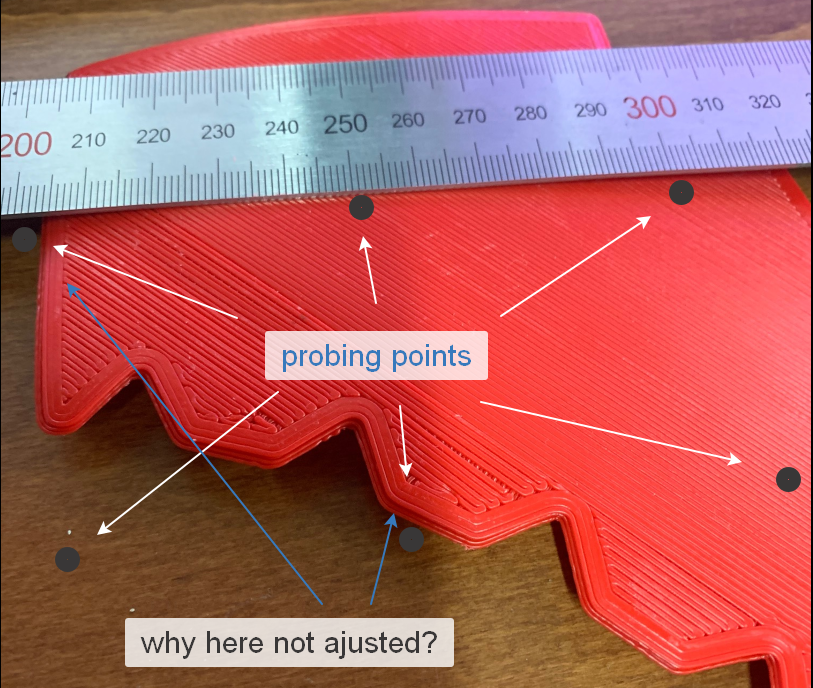

I understand that a printer of that size is difficult to handle. Fact is that the last two height maps you published do not look bad, they are just not in sync with the bed plane. In other words: the white grid in the height maps represents the result of your bed levelling, the coloured plane (mostly blue) demonstrates the measured distances at the probing points. These two „planes“ are way too far off from each other.

Mesh grid compensation is not a substitute for proper bed levelling, ist is just an additional aid to smoothen the first layers. So, after you warm up bed and chamber, level the bed first, then, calibrate the mesh. If the resulting „planes“ do not match, something is wrong with your printer’s geometry.

-

@Dep said in Mesh calibration not working or what am I doing wrong?:

I agree with you that the smaller the distance between the points, the better the calibration.

But the glass on the table cannot be bent strongly at a distance of 50mm.

Look at the photo: why the calibration is not performed?

Hi,

Could you please print a simple 5 mm thick rectangle large enough that it includes that 6 probe points.

The irregular nature of the object you are printing may be hiding another problem.

Thanks.

Frederick

-

@infiniteloop The height maps are far apart because the table was not heated. Now I will make a new card on the heated table.

However, even if they do not match. I want to understand - are there any restrictions on the size of the shift?

-

@fcwilt

I will try to do. But it will take at least 4 hours

-

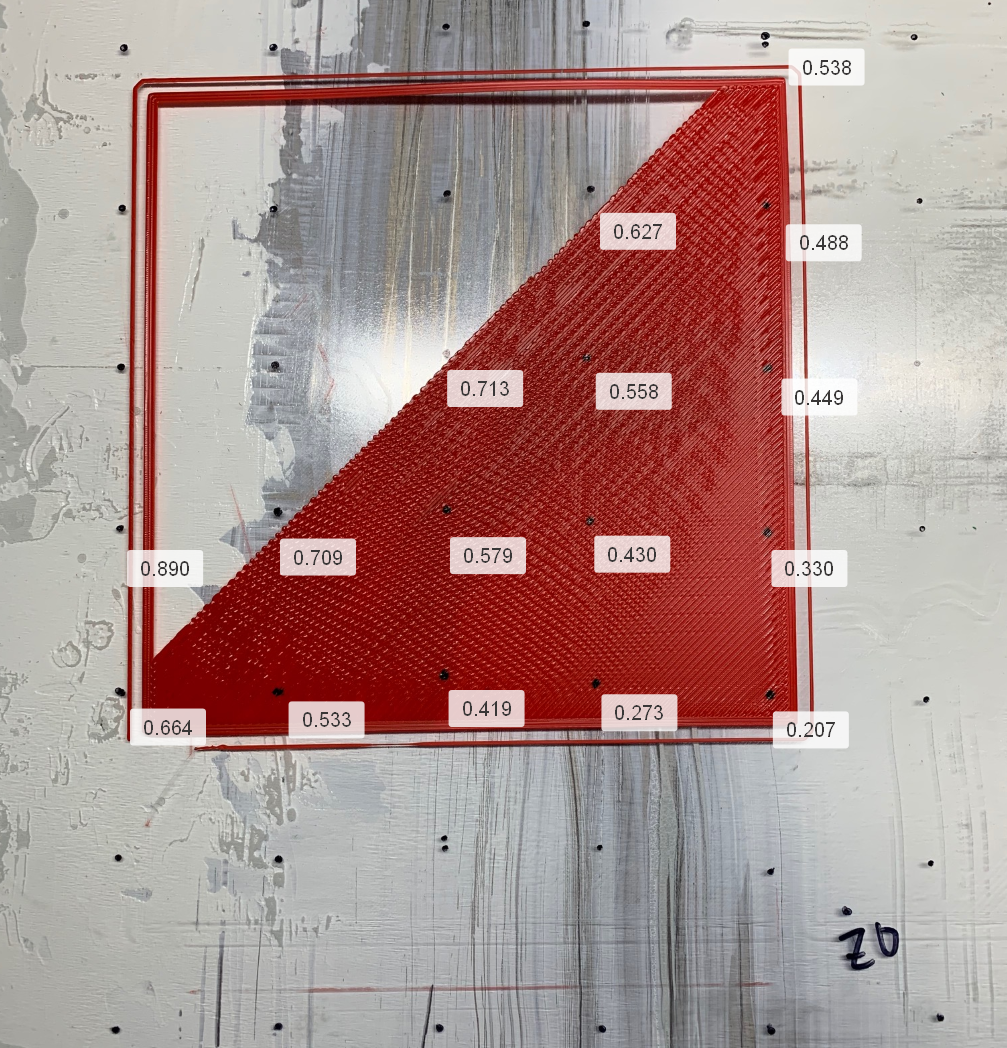

I heated the table. Here is the result:

RepRapFirmware height map file v2, min error -0.056, max error 1.271, mean 0.512, deviation 0.270 xmin,xmax,ymin,ymax,radius,xspacing,yspacing,xnum,ynum 450.00,950.00,120.00,620.00,-1.00,50.00,50.00,11,11 0.210, 0.144, 0.077, -0.005, -0.047, -0.056, 0.005, 0.057, 0.157, 0.285, 0.423 0.433, 0.364, 0.267, 0.133, 0.083, 0.066, 0.102, 0.179, 0.279, 0.408, 0.553 0.664, 0.533, 0.419, 0.273, 0.207, 0.222, 0.234, 0.285, 0.372, 0.501, 0.646 0.890, 0.709, 0.579, 0.430, 0.330, 0.267, 0.302, 0.367, 0.443, 0.563, 0.721 1.078, 0.899, 0.713, 0.558, 0.449, 0.400, 0.405, 0.452, 0.515, 0.649, 0.782 1.240, 1.019, 0.818, 0.627, 0.488, 0.458, 0.484, 0.534, 0.601, 0.694, 0.840 1.271, 1.028, 0.831, 0.665, 0.538, 0.483, 0.478, 0.498, 0.598, 0.699, 0.806 1.205, 0.980, 0.773, 0.632, 0.508, 0.471, 0.454, 0.509, 0.572, 0.698, 0.808 1.080, 0.846, 0.679, 0.522, 0.405, 0.383, 0.417, 0.469, 0.556, 0.689, 0.792 0.829, 0.671, 0.544, 0.382, 0.310, 0.332, 0.350, 0.437, 0.555, 0.698, 0.823 0.687, 0.558, 0.428, 0.302, 0.217, 0.232, 0.278, 0.356, 0.468, 0.605, 0.752

And now I’ll try to print a 200 x 200 square ...

-

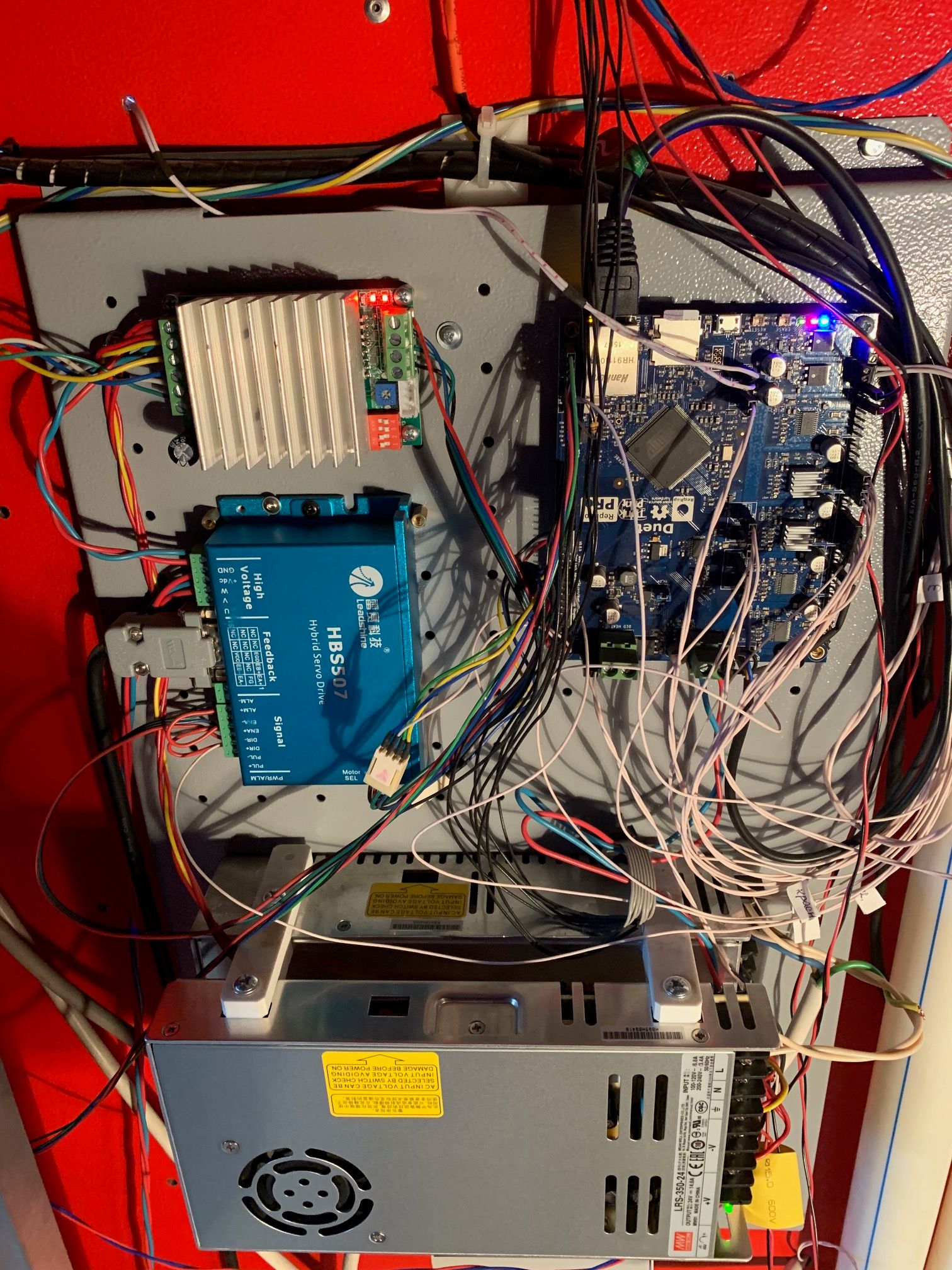

M906 X1500 Y0 Z0 E1200 I100 ; Set motor currents (mA) and motor idle factor in per cent

looks weird. How does this even work? I also don't think, that test-printing makes sense currently.

M92 X100 Y160 Z1600 E157 ; Set steps per mm

I havent seen many builds like this. Can you post a photo. Why is Steps per mm all different?

-

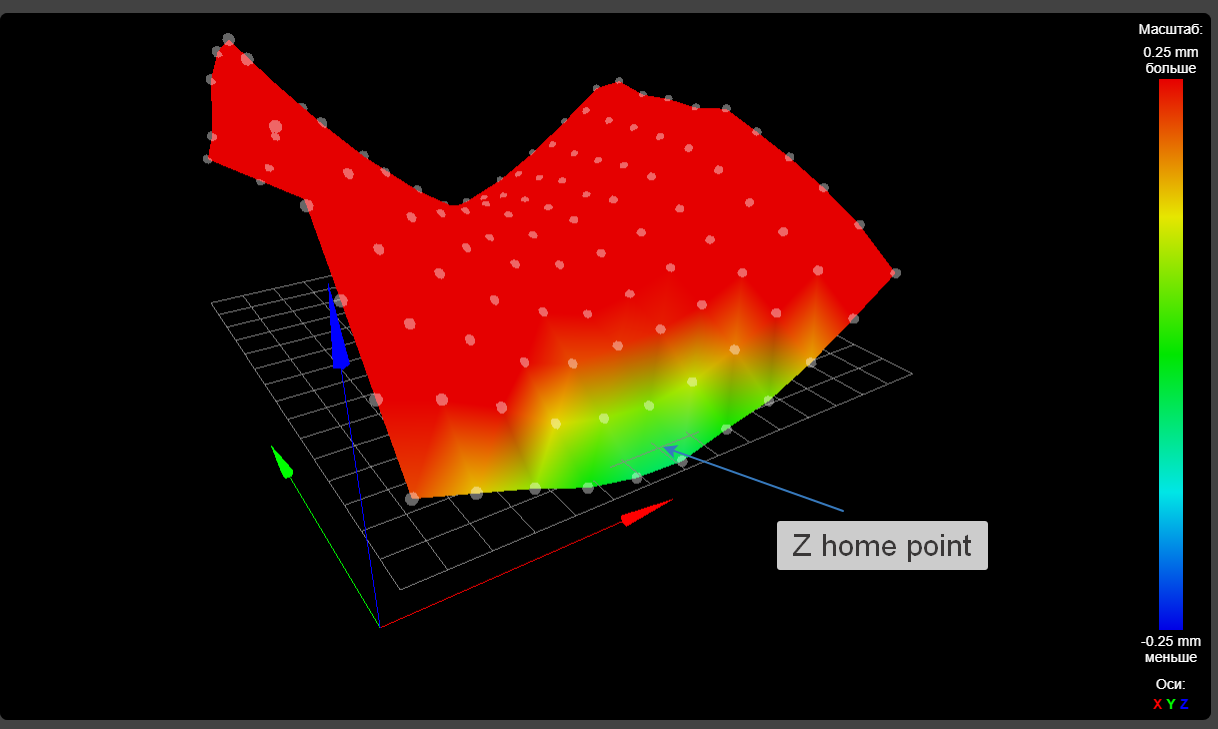

I made a crude drawing what happens with a sagging x axis to the trigger height.

the drawing is a bit over the top, but its just to show the problem.because of the curve created by the sagging the trigger heights varies, which causes incorrect heights to be reported.

-

@Veti Honestly, I did not understand your picture. Could be a little more detailed

-

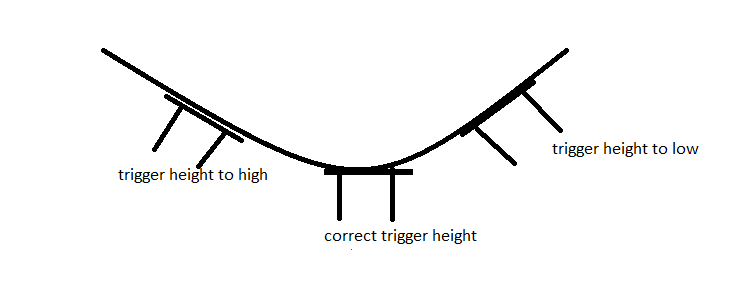

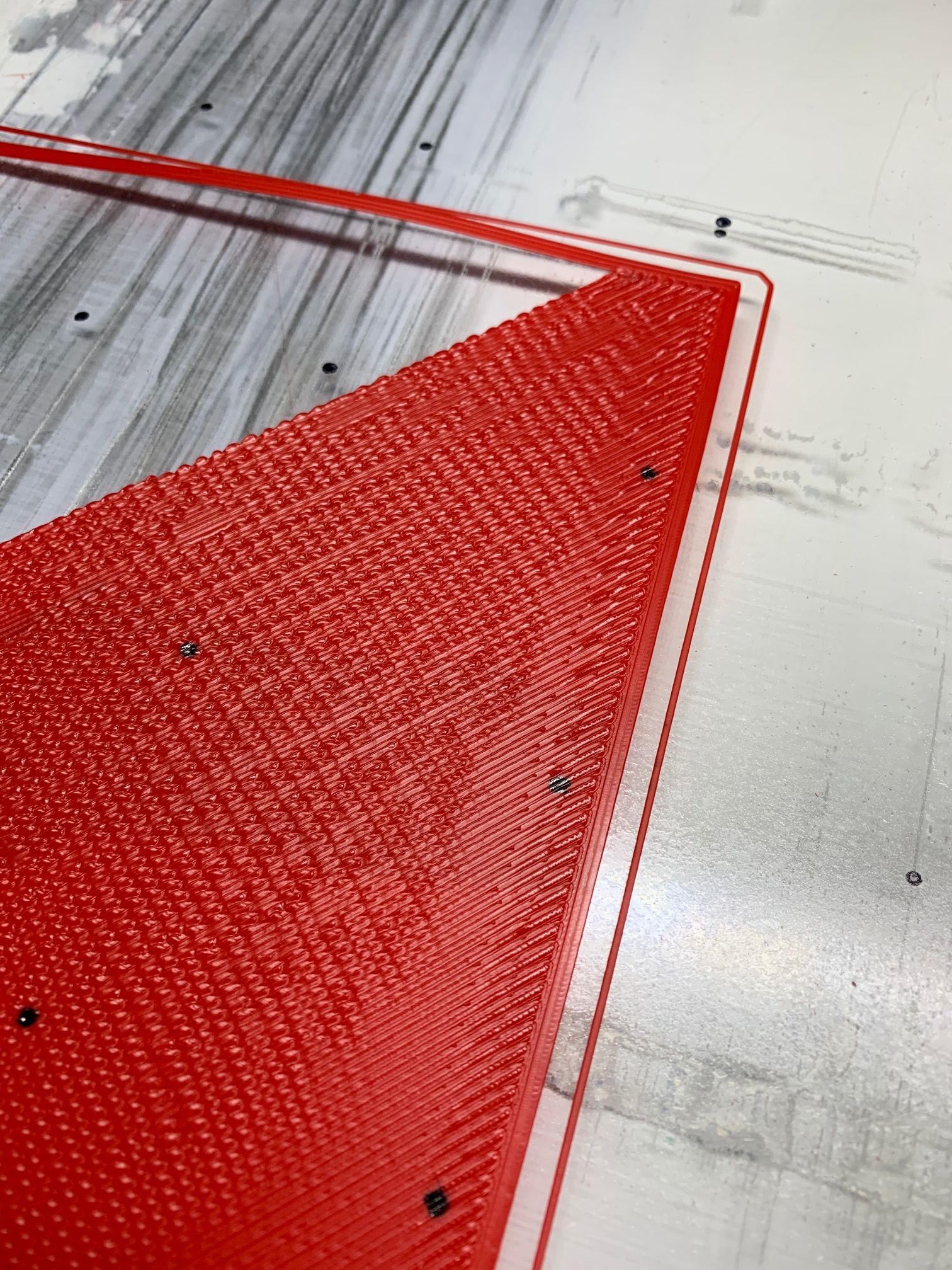

Pictures of the result:

I should have made the bed a little lower, but it’s already clearly seen that the compensation is insufficient.

-

@dgrat said in Mesh calibration not working or what am I doing wrong?:

M906 X1500 Y0 Z0 E1200 I100

This is because the Y and Z motors are connected to an external driver.

-

@Dep

the images shows your over 1 meter long x axis.

it bends under its own weightit shows your hotend assembly at 3 different positions.

- at an angle in the at around 1/3 the length

- not at an angle in the middle

- at an angle at around 2/3 the length

because the entire hotend assembly is at an angle at position 1 and 3 the probe value will be off because in position 1 the nozzle is lower and in position 3 the nozzle is higher in comparison to the probes trigger point.

lets assume you have a trigger height of 5mm

i.e. at position 2 this is correct.

at position 1 your actual trigger height might be 6mm

at position your actual trigger height might be 4mm.so your printer in the middle would be fine.

the further you move to the left your prints would get squashd

the further you move to the right your prints would be spaced or not stick to the bed.p.s that bed surface looks like old scrap metal.

-

@Veti Now I understand what you mean.

I do not agree. The deflection of the extruder beam is almost zero. When it was mounted, we did a preload up. And checked on the line.

And even if there is a sag, then this is a hundredth of a millimeter.

The upper surface of the table is made of aluminum. To equalize and improve thermal conductivity, thermal grease was applied under the glass.