Extruder skipping / underextruding

-

@jens55 said in Extruder skipping / underextruding:

Could a partially plugged nozzle produce these kind of symptoms ? Size of nozzle selected in slicer doesn't match physical nozzle size ? Are you maybe exceeding the melting capability of your hot end ? Just throwing out some ideas ...

+1 on the plugged nozzle. Also are you sure the extruder steps is calibrated correctly in your new Duet config?

-

I'll take another look at the nozzle to see if its plugged. I'll report back on that later today. Not ruling anything out, but the print prior to board swap was fine...

I did tune steps/mm for filament, as extruding at 1mm/sec seemed to work w/o skipping so i could do a few tests measuring 100mm extrusion cycles.

-

I had the same issue and it was the thermistor settings. Depending in what thermistor you are using the values need to match. I used the generic settings on an E3D thermistor and it was ~45 degrees low.

-

@widgetNinja said in Extruder skipping / underextruding:

I'll take another look at the nozzle to see if its plugged. I'll report back on that later today. Not ruling anything out, but the print prior to board swap was fine...

I did tune steps/mm for filament, as extruding at 1mm/sec seemed to work w/o skipping so i could do a few tests measuring 100mm extrusion cycles.

General accepted wisdom is to do extrusion calibration with the filament not going through the hot end (or not having a nozzle installed). When you say that you did calibration because it worked at 1 mm/sec, are you saying you can't do calibration at 5mm/sec without the filament going through the nozzle ?

If you get skipping at 5 mm/sec while not going through the nozzle then all previous suggestions are off the mark and there is something totally different going on. -

Just for curiosity sake, what size nozzle are you using and what size filament are you using?

On the assumption that you are using 1.75 mm filament and if my basic math is correct, you would be attempting to extrude 12 cubic mm of filament per second. The figure that I have always worked with as a maximum is 10 cubic mm per second with a standard heat block and 0.4 mm nozzle.

If you are exceeding the volume capacity you will get skipping without a doubt.

You have established that 1 mm/sec works. I suggest that you try 2,3 and 4 mm/sec. You may get skipping at 4 mm/sec but 2 and 3 should work. -

@bricor Could i trouble you to share the heater line with the settings you used? I was leaning towards something along those lines, but couldn't find a Wanhao/Monoprice one to try.

@jens55 Thanks for suggestion re doing test w/o nozzle. Guess i fail in regards to generally accepted wisdom as I had it on! I'll redo that test tonight too. (Skipping at 5mm was indeed w/ nozzle on)

-

@jens55 Confirmed that i am using 1.75 mm filament. I think that 5mm/sec extrusion may be a red herring. Can i upload the actual generated gcode of the print so we can see speeds its using? Or is there a specific gcode line i can share to provide insight? Using same slic3r outputs/parameters i've always used as previous board was considered reprap as well.

-

I am a simple person and gcode would probably confuse me more than it would help. I would suggest doing all of the testing using straight gcode via the gcode console. This will eliminate anything odd in the generated g-code file.

The following may not be correct but hopefully others will chime in and correct me:

G1 E10 f300

If I got this right is should be a move (G1) Extruder for 10 mm (E10) at the speed of 5mm/sec or 300 mm/min (F300)

If the 5 mm/sec is an issue you should hear skipping. You can increase the amount of the overall extrusion to give you a longer time to listen for skips (Ie E50) and you can play with the speed and reduce that to let's say F150 to give you 2.5 mm/sec which should work without skipping.

I guess posting the gcode can't hurt either. -

@widgetNinja said in Extruder skipping / underextruding:

Monoprice Select Plus

are you sure that your thermistor values are correct?

-

@jens55 I'll test tonight and report back. Thanks for the great instructions.

-

@Veti I absolutely am not!

I tried doing some searching on what thermistors they used on this, and all i could find was 'generic' information about them being 100k. New to this, but i did test that it read about 100k on my multi-meter, at about 25C.

I tried doing some searching on what thermistors they used on this, and all i could find was 'generic' information about them being 100k. New to this, but i did test that it read about 100k on my multi-meter, at about 25C.Suggestions on steps to take / Tests to perform?

-

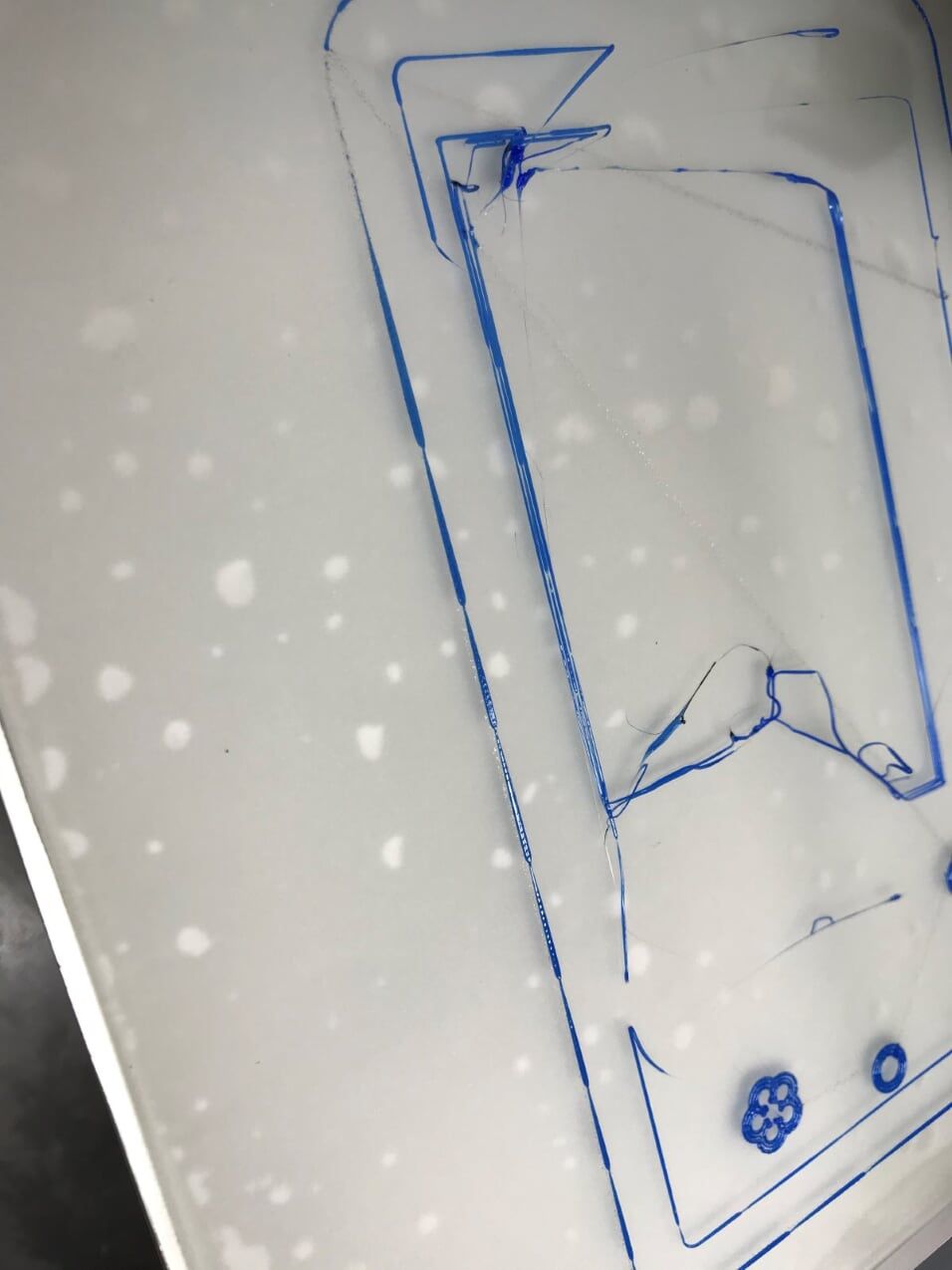

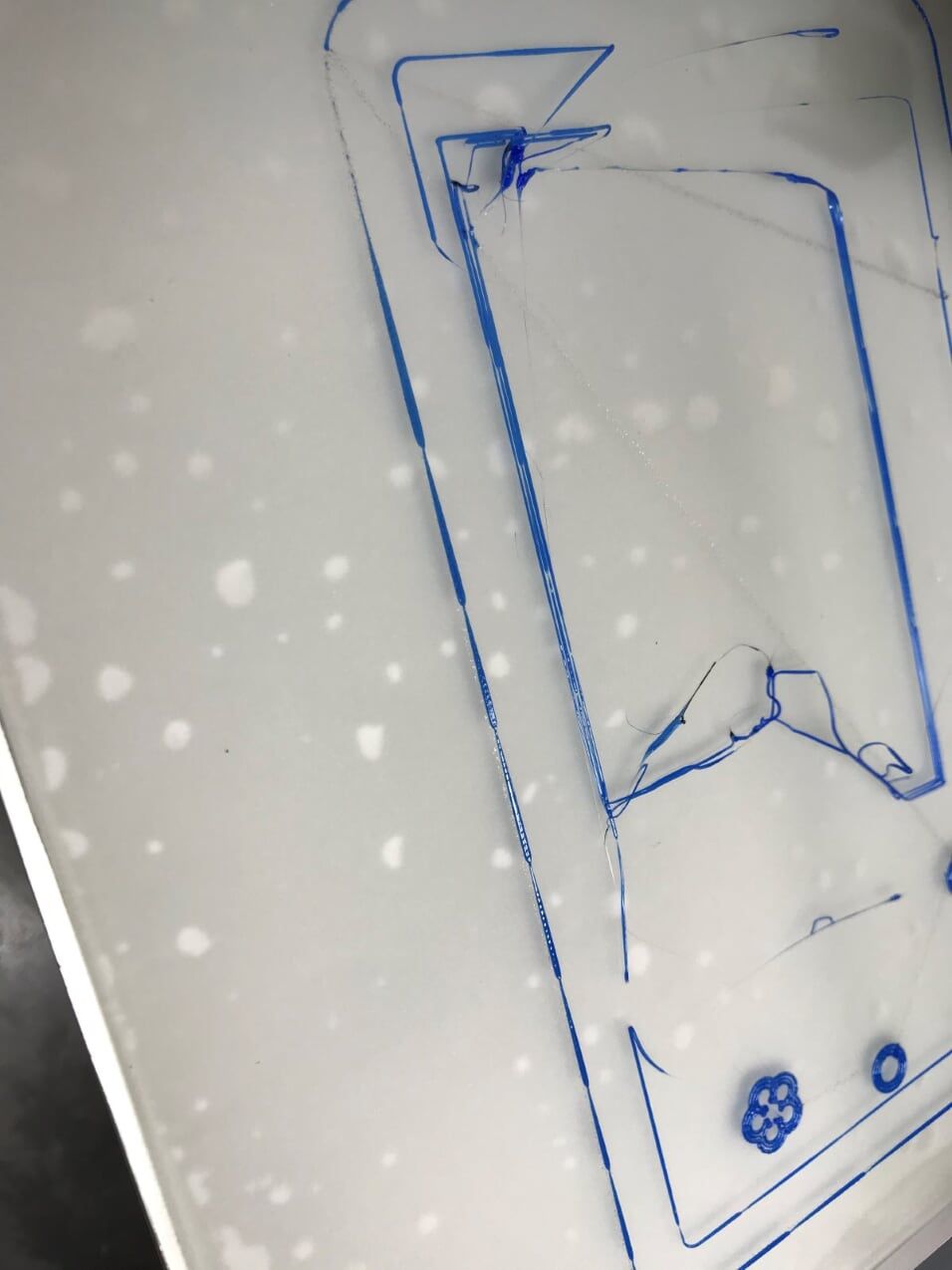

If it helps, here is a picture I took yesterday. On the brim (right word?) you can see it get thick/thin that seemed to correlate with the clicking/skipping.

-

@widgetNinja said in Extruder skipping / underextruding:

I absolutely am not! I tried doing some searching on what thermistors they used on this, and all i could find was 'generic' information about them being 100k. New to this, but i did test that it read about 100k on my multi-meter, at about 25C.

Suggestions on steps to take / Tests to perform?if the settings are off, the temperature could easily be off by 40 or more degrees.

all 100k should read 100k at 25C.easiest would be to replace the thermistor with ones where you know what they are.

otherwise you need a known good thermometer. heat up water to different temperatures and note down the resistance.

-

@widgetNinja said in Extruder skipping / underextruding:

If it helps, here is a picture I took yesterday. On the brim (right word?) you can see it get thick/thin that seemed to correlate with the clicking/skipping.

Looking at that brim, I have the uneasy feeling that something else is not right. The way I view things, under extrusion would generate a continuous undersized line with maybe a tad of a hiccup when it skips a step. This looks more like maybe the clearance between nozzle and bed is not quite right (too large).

In other words, you could have more then just a single issue and I would suggest trying to separate them as much as possible and testing for them individually.

I would suggest testing your extruder flow problems with the nozzle in mid air with the previously mentioned gcode lines to find out if there is skipping. Only after that is sorted would I suggest looking at the nozzle to bed distance. -

-

@Veti Is there a favored thermistor to buy, that has the data tables etc? Its only a few bucks so i'll get an order in to cover my bases.

-

best known ones are 104GT-2 Semitec. (used by e3d) this is prob the best choice.

you could also get a PT1000.

-

@Veti Thanks!

-

@widgetNinja , You can get a cheap multimeter that has a temperature probe and it might be of more value in the long run.

I have used all kinds of different thermistors and they were all equally inaccurate. None of them were out by more than plus or minus 20 degrees and most were within 5 degrees when compared to a commercial grade thermocouple and instrument.

Yes it's possible that you have a weird thermocouple but since you said it was about 100k at room temperature, I am not so sure.

A spare is always a good thing but if you are like me and order from China, you could be waiting 3 or more weeks.

I lust after a PT1000 but at $12.99 from filastruder.com it's a bit on the dear side and it is not a bead so won't fit a bunch of heater blocks. It is much more accurate but unless you have multiple printers, you don't need to know an accurate temperature. You get used to your printer with your filament and you will know what temperature you will need for your setup.

It is fairly easy to verify your thermistor as well. Measure resistance at 25C as you did, measure resistance in boiling water (don't forget to compensate for elevation, water only boils at 100C at sea level) and then plug those values into formulas available on the internet (might not even be required, I did it once and it wasn't an 'ahah' type moment) -

@Veti said in Extruder skipping / underextruding:

best known ones are 104GT-2 Semitec. (used by e3d) this is prob the best choice.

you could also get a PT1000.

This. A good thermistor is one of the best and most underrated upgrades you can do. We rely on melting thermoplastic and yet we use the cheapest random generic chinese thermistors.