Mesh bed compensation issues

-

-

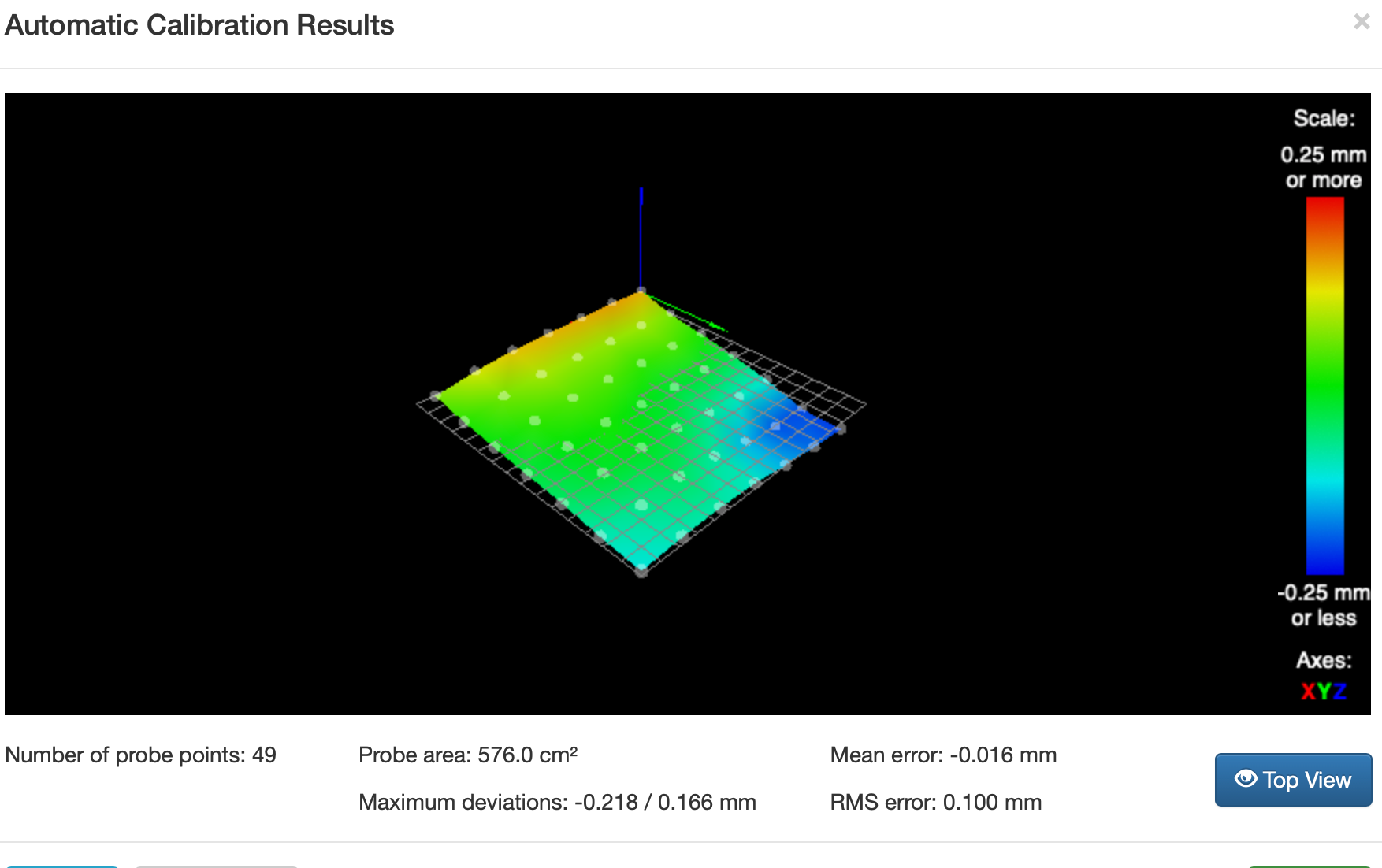

G31 P25 X35.0 Y0 Z0.2800.280 is very low for a trigger height on a BLTouch. When mounted correctly with the bottom of the probe body 8mm above the nozzle tip the trigger height should be close to 2mm.

Have you used this guide for calibrating the probe?

https://duet3d.dozuki.com/Wiki/Test_and_calibrate_the_Z_probe

-

@Phaedrux Yes I have done it multiple times...

-

Hi,

Do you have anyway to level your bed?

It looks fairly consistent except for that dip in the left-rear but it clearly is not as level, overall, as it could be.

Frederick

-

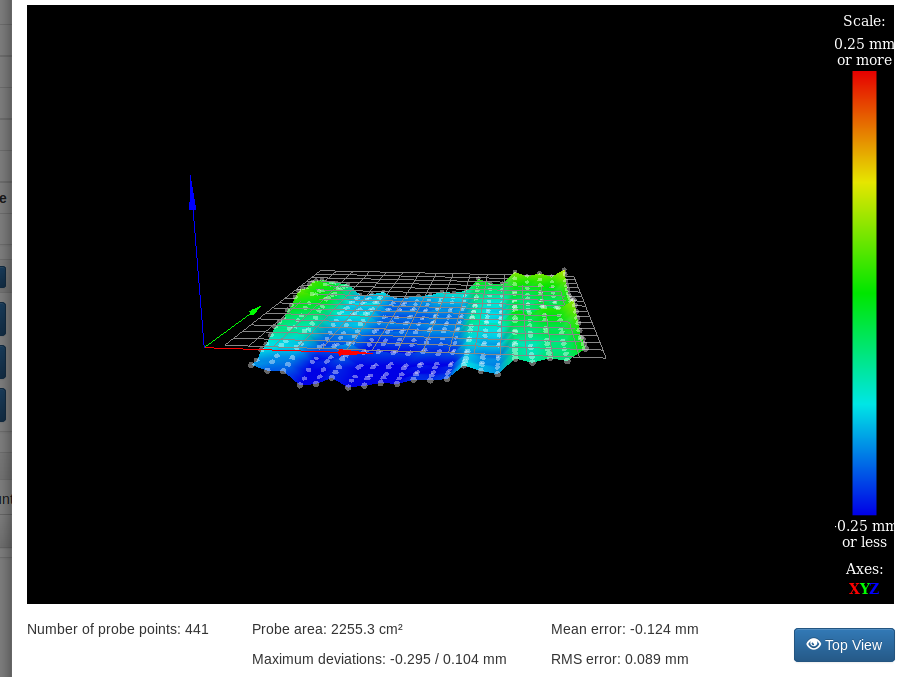

Just for laughs, here is my bed mesh map ... I wish I could have a nice looking bed like what is being talked about here.

-

dc42 has pointed out that "peaks and valleys" like you have indicate something is shifting when the hotend is in moving one direction as opposed to the other.

Frederick

-

Yes, and I agree with that thinking ... but in this case the mesh is generated along the X axis and the valleys are going along the Y axis so this explanation doesn't work for me.

I am assuming that the general dip in the middle is because of a very long gantry and a tiny extrusion (CR10 S5) although it is a bit odd that the dip is not in the center which is what I would expect. -

I managed yesterday to have a consistent 1st layer (in all 4 corners and without bed mesh leveling).

However after a while a get the following warping… (PLA )

Even if I lower the nozzle as low as it gets I still get the same problem…

Any clues ?

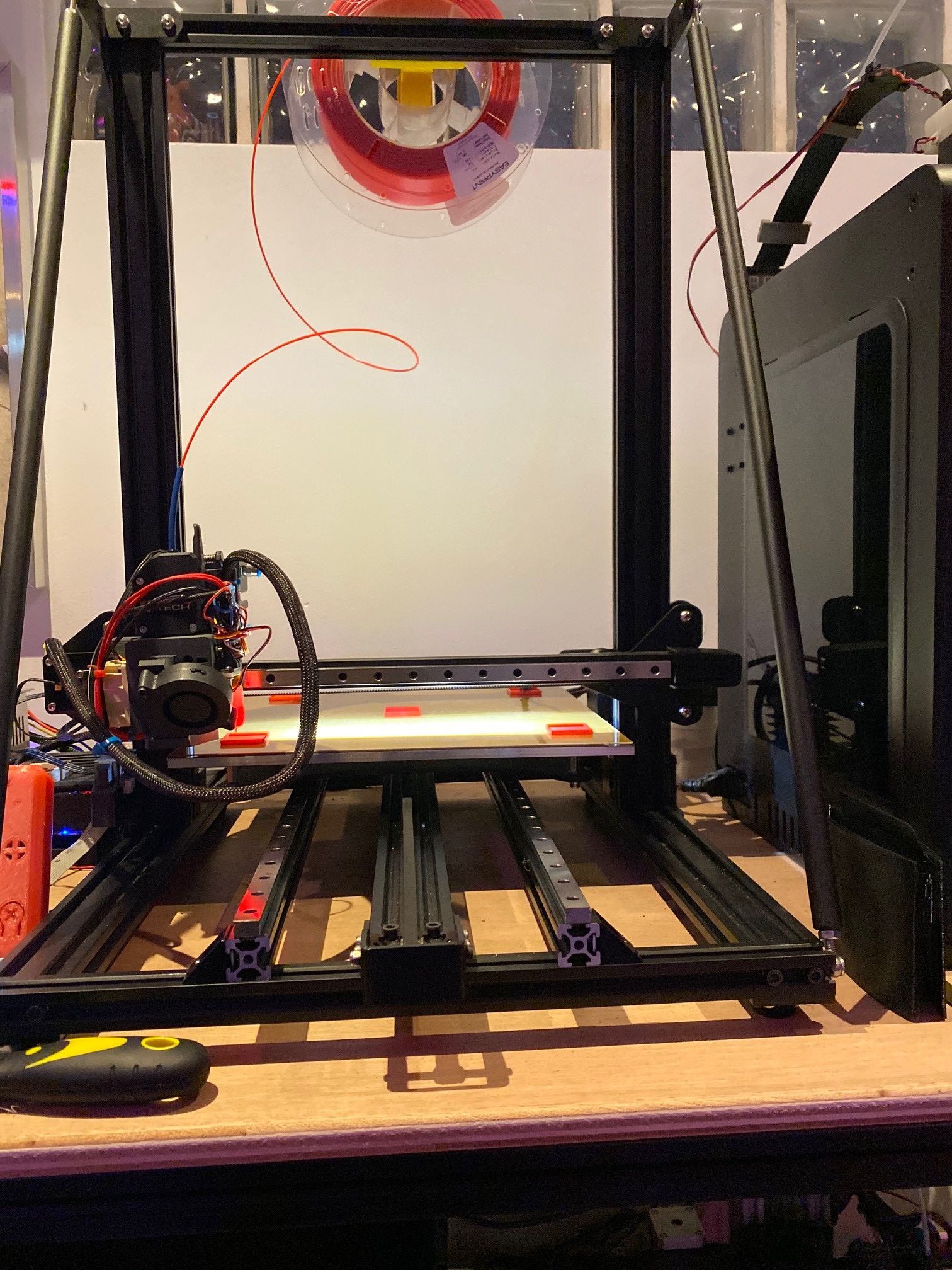

Hereby my bed setup

-

That is not at all unusual. I run a glass bed and my first response to something like that is to either increase squish or increase bed heat.

In some instances printing with a brim helps or on very large prints you might have to design micky mouse ears into the object - largish round pads at any sharp corners that are a couple or so layers tall when a standard brim isn't strong enough. -

@jens55 Even with brim i have the same issue... I cannot increase further the squish it will stop extrude. And you see i have warping with pla in objects of 30x30mm width....

I have my bed at 70C so it is hot enough i believe. -

Assuming your temperature is measured ok, then 70 'should' be ok but I print PLA at a bed temperature of 85 for the first layer and 75 thereafter. Unfortunately I do not know anything about the bed surface that you are using so can't really advise more. All I can say is that this is VERY common and you should find many suggestions when you do an internet search.

Generally what you see is caused by poor adhesion of the first layer.

What is your layer height? What is the gap between nozzle and print bed? What is your extruder temperature ?

Do you see this fault at only one location, multiple or all ? -

@jens55 layer high = 200, nozzle temp 215-220, In most places on the bed i have the same issue. I get the same issue with raft as well. The raft is warping... I will try to raise temp 5-10 degrees and if the problem persists maybe i switch to buildtak....

-

What about the nozzle to bed distance for the first layer ?

When you print with a brim, have you measured the thickness of the brim at multiple points all around the model ? If you are printing with a first layer height of 0.2 mm then the brim (which is 1 layer if you are using the Cura slicer) should be less than 0.2mm. That is your squish.

If you are using a 0.4 mm nozzle, is you trace width at least 0.4 mm? What does the surface of your print look like - does it appear you have full surface coverage with a reasonably smooth surface finish ?

There are many factors that affect adhesion so it is quite difficult for me to cover everything that could possibly go wrong.

With the print finished and the bed still at operating temperature, can you remove the print (careful, you don't want to damage your print surface!). If the print pops off with a little hand pressure then adhesion is not good enough.

Did you clean the print surface as per manufacturer suggestion before printing ?

Does the manufacturer recommend adhesion improvers such as glue, hairspray or what-not ? -

Hi,

I print PLA at 190/60.

Overall speed 90, first last speed 20%.

Part fan is 0 for first layer, increasing by 20 per layer.

My build surface is CCTREE and it works well.

I sometimes need to use baby-stepping to get the first layer "squish" right. I print a 5 perimeter skirt to allow making this adjustment.

Frederick