Constant layer shift along y-axis

-

-

Some details of your setup would be useful to know. See https://forum.duet3d.com/topic/5909/guide-for-posting-requests-for-help

Ian

-

Here is my config

- ; Drives

- M569 P0 S1 ; physical drive 0 goes forwards

- M569 P1 S1 ; physical drive 1 goes forwards

- M569 P2 S1 ; physical drive 2 goes forwards

- M569 P3 S0 ; physical drive 3 goes forwards

- M584 X0 Y1 Z2 E3 ; set drive mapping

- M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

- M92 X80.00 Y80.00 Z400.00 E180.00 ; set steps per mm

- M566 X30.00 Y30.00 Z30.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

- M203 X6000.00 Y6000.00 Z1200.00 E1200.00 ; set maximum speeds (mm/min)

- M201 X500.00 Y500.00 Z50.00 E1000.00 ; set accelerations (mm/s^2)

- M906 X1500 Y1700 Z1500 E1700 I30 ; set motor currents (mA) and motor idle factor in per cent

- M84 S30 ; Set idle timeout

- ; Axis Limits

- M208 X0 Y0 Z0 S1 ; set axis minima

- M208 X220 Y220 Z220 S0 ; set axis maxima

- ; Endstops

- M574 X1 Y1 Z2 S1 ; set active low and disabled endstops

- ; Z-Probe

- M307 H3 A-1 C-1 D-1 ; disable heater on PWM channel for BLTouch

- M558 P9 H10 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

- G31 P500 X0 Y0 Z3.0 ; set Z probe trigger value, offset and trigger height

- M557 X50:220 Y10:180 S42.5 ; define mesh grid

- ; Heaters

- M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0

- M143 H0 S120 ; set temperature limit for heater 0 to 120C

- M305 P1 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 1

- M143 H1 S280 ; set temperature limit for heater 1 to 280C

- ; Fans

- M106 P0 S0.3 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

- M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

- M106 P2 S1 I0 F500 H1 T45

- ; Tools

- M563 P0 D0 H1 F0 ; define tool 0

- G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

- G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

-

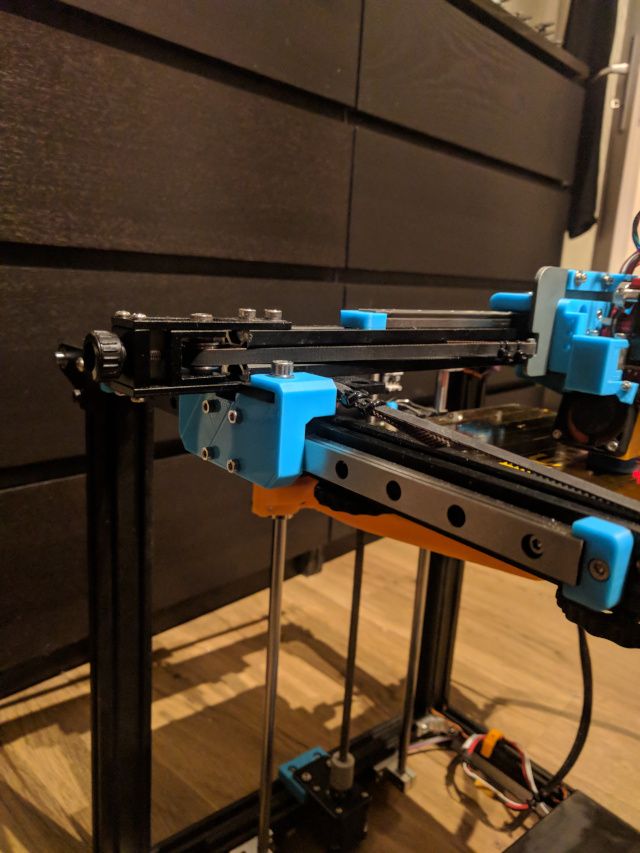

How did you ensure that the Z axis was orthogonal to both X and Y when you built the machine?

-

your frame or at least your axis are not square to each other. is this the first time the printer has been assembled?

-

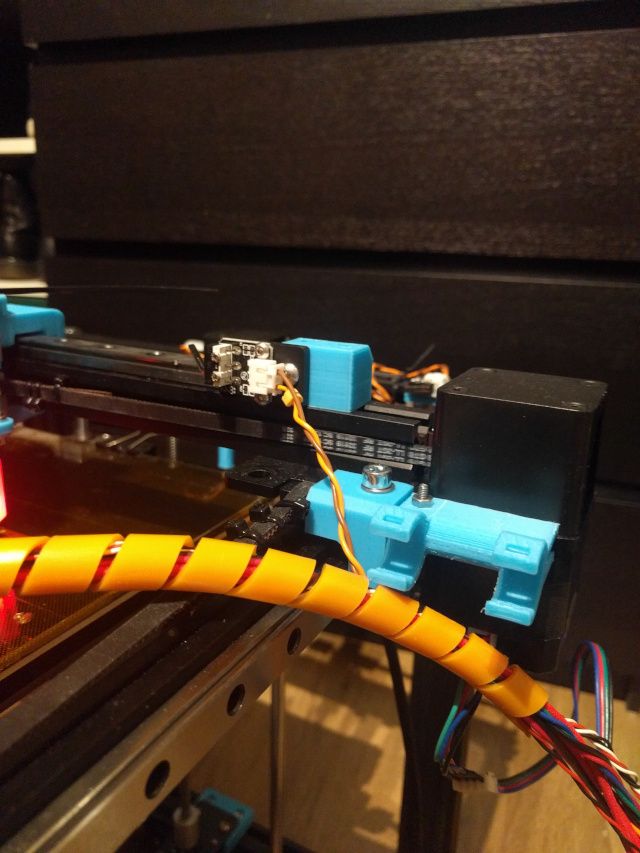

unrelated, but your belt path is also extremely un-parallel to the frame, which will result in different steps/mm depending on position and also belt tension.

-

Yes it is the first time this printer is assembled in that way. Nevertheless, the belt does not need to be parallel/flat to the extrusion. I rather think that one axis might not be straight, but how this should be possible in a cartesian? Even if y would be tilted 20 degree it would only matter for the first layer.

-

@dgrat said in Constant layer shift along y-axis:

Nevertheless, the belt does not need to be parallel/flat to the extrusion.

it does create a small scaling error due to the angle of the belt.

-

-

I re-assembled the x-axis ensured it is more or less orthogonal and the error disappeared

-

-

Did you correct the angle of the Y belt? Perhaps it's binding?

-

Loose pulley, check that the bed is mounted fixed