Pressure Advance Calibration

-

@OBELIKS said in Pressure Advance Calibration:

@Munce31 If you are using the script @jens55 posted, you can add

print("M117 %.3f" % pressure_advance)after

print("M572 D0 S%.3f" % pressure_advance)Hi @OBELIKS thanks for providing that. It'll make it easier to watch the test print and see what pressure advance it current is running at.

-

I was reading though some of this to take a look at my own values.

What is quite odd is that the point at which the fast areas and slow areas are equal in width is at 1.75 - which seems crazy high according to the documentation. I am using a bowden tube of capricorn of length ~600mm. It has a bondtech extruder and a smart effector/v6 combo on the output.

I was using the original script from the start.

The other relevant settings from config:

M92 X80.00 Y80.00 Z80.00 E830.00 ; Set steps per mm M566 X1200.00 Y1200.00 Z1200.00 E40.00 ; Set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z18000.00 E5000.00 ; Set maximum speeds (mm/min) M201 X3000.00 Y3000.00 Z3000.00 E120.00 ; Set accelerations (mm/s^2) M906 X1000.00 Y1000.00 Z1000.00 E500.00 I30 ; Set motor currents (mA) and motor idle factor in per centI also just figured out this:

M92 E820 M592 D0 A0.001246 B0.000406 T230Do these seem reasonable? The max instanteous speed sounds low compared to one post above.

This is an upgraded mini kossel.

-

@zzing said in Pressure Advance Calibration:

M566 X1200.00 Y1200.00 Z1200.00 E40.00 ; Set maximum instantaneous speed changes (mm/min)Do these seem reasonable? The max instanteous speed sounds low compared to one post above.

These values really are rather odd. How did you find such a low max inst. speed value for E? I have mine at 1800 and think I am still rather on the low end. Also this 40 of yours will probably lower total print speed.

-

I am not sure if I set that or it was configured from the tool to build a config. With all those other values I could probably use realistic values for a delta machine.

I can retest then.

-

If a user has a very geared down extruder, low E jerk is required (if using pressure advance). IIRC, extruder jerk is only used when pressure advance is in effect. Otherwise, it has no effect on print time. E Accel has an effect on print time when set too low, with or without pressure advance.

My extruder can't use correct amounts of pressure advance without a low E jerk value of ~90.

-

I have very strange results when trying to calibrate PA.

Here are the speed, acceleration and jerk settings:

M203 X15000.00 Y15000.00 Z15000.00 E6000.00

M201 X2000.00 Y2000.00 Z2000.00 E2000.00

M566 X1200.00 Y1200.00 Z1200.00 E1200.00

I'm using BMG cloned extruder (if matters) with bowden of 550 mm and ID 2 mm.

Used python script to print patterns with the following settings:

extrusion_width = 0.5 (nozzle is 0.4 actually, 0.5 is used in slicer as an extrusion width)

layer_height = 0.2

filament_diameter = 1.72 (measured with calipers)travel_speed = 150

first_layer_speed = 15

slow_speed = 5

fast_speed = 70I tried PA settings from 0.1 to 1.0 at first and there were no signs of PA working. Further experiments showed that noticable result is there only in range 1.5 to 1.9. But this looks insane... Or this is normal?

Also i noticed that the speed is limited to 63-65 mm/s (due to too low extruder settings possibly?). -

@SnakeSP Perhaps try this method of tuning pressure advance.

-

@Phaedrux

I tried the first one, with the python script.

Will try the second one, with the cube, but need to understand how to make Simplify3d to align seam at the center of the side, for now i can only align it to one of the corners.One more thing still bothers me: i have not yet found the proper settings for BMG extruder (speed, acceleration, jerk) there are very different number said to be best in every topic i've read and there is nothing about it on Bondtech site. Can you point me where can i find such info please?

-

No matter what i try to set with "Choose start point..." the beginning of the line is always in the corner. Same for Cura. Does anyone know how to align Z seam to the center of the cube's side?

-

@SnakeSP not sure about simplify but with Cura you choose it specified and then choose an x y coordinate for the seam.

-

@Phaedrux

Yes, i tried that but Cura still places seam to the corner... -

Z seam alignment - User specified

Z seam position - back

Seam corner preference - noneProduces the desired result. That's in 4.4.1. In older versions there was an X and Y position you could specify. The setting is still there in the settings visibility filter, but it's not being shown and I'm not sure what's blocking it. Regardless, setting it to back, front, left, or right works to align it to a face.

-

@Phaedrux

Does not work for me

Cura 4.4.1, settings as you've specified - seam is generated in one of the corners no matter what coordinates i set.

Can you share a gcode of the cube (20x20x20) with a single perimeter with a seam in the center of one of the sides so i can modify it for my printer, please? -

@SnakeSP said in Pressure Advance Calibration:

@Phaedrux

Does not work for me

Cura 4.4.1, settings as you've specified - seam is generated in one of the corners no matter what coordinates i set.

Can you share a gcode of the cube (20x20x20) with a single perimeter with a seam in the center of one of the sides so i can modify it for my printer, please? -

@burtoogle Thanks!

-

@SnakeSP sorry for providing misinformation. I'm surprised that the stock Cura build won't allow it.

-

thanks for this thread!

after playing a bit with pressure advance i was able to boost the quality of at least one print and i feel the shape of the model matters a lot. pressure advance enabled me to print a model with tiny 45 degree overhanging sharp corners.

-

I have tuned PA according to the method in the wiki, not with the script, but by printing a 100mm cube and adjusting on the fly. I have settled on 0.7, with a bowden tube of around 480mm length.

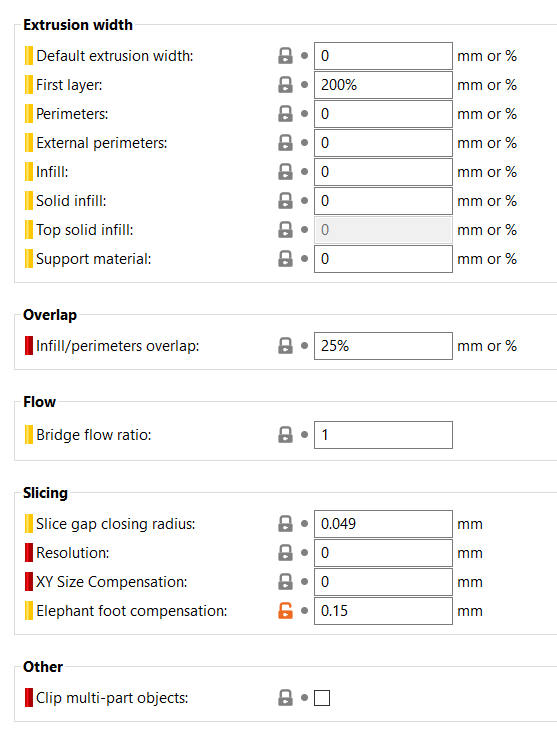

While my corners, overall surface and z-seam look better, I'm now getting gaps in the infill - not in the parameters though. I looked in PrusaSlicer and the only setting I can find that mentions overlap is "Infill/Perimeters overlap". By default, it was set to 25%. Is this the value I need to change?

If yes, what should I change it to? -

@devleon yes the wiki does mention that maps may form. It's like the slicers have been compensating for bulging line ends already. Try an additional 3-5%.

-

I changed the value from 25%, to 30% and to 40% with no difference.

Thinking more about it, I don't think it's Infill/Perimeter Overlap. Shouldn't it be the extrusion width for solid infill? After all the lines are now thinner on the first layer than before. This is what my config looks like in PrusaSlicer:

Printing the same G-Code with PA disabled, and I get a beautiful first and second layer with no gaps. As soon as PA is enabled, I get gaps in the first and second layer between the individual lines of filament.