Problems with the Z axis, falls down

-

Hello

My name is Marcel. I try to build a 3D-Printer (cartesian printer) of my own. I am self-taught.

Here are the data of the printer:- board: Duet3 Board

- Firmware: RepRap version 3

- Configuration tool: Version 2.1.3.

- Driving force: Y- and X-axis NEMA 23, Z-axis 2x NEMA 34 (34BK50-120) with magnet brake

- Extruder: Typhoon with NEMA 23

- process route: Y-axis 1100 mm

X-axis 600 mm

Z-axis 900 mm - total weight: about 180 kg

The printbed weights about 45 kg (a aluminium frame, a aluminium plate, a heating mat and a glas plate)

So far everything works fine and the axis do what they should do. But as soon as I press the stop button (reset), the Z-axis falls down. This costs me the first Duet3 board (it's burned (destroyed)). I can prevent that with the magnetic brake by activating the brake beforehand. So far so good!!!

The big issue is that as soon as the Z-axis stops after a movement, it drops down. Without the glas plate, it can hold the position but with the glas plate it doesn't work. It's clear to me that the glasplate is too heavy. I suspect it is the holding current.

Now the questions: - Can I increase the holding current?

- Can I set the holding current in the config?

- Can I keep the Z-axis-motors under constant current?

I would be happy for help. If there is no solution for my problem, I will have to change the printer to a fixed printer plate,

-

Changing the z drive arrangement to a worm drive system is the best solution I've been advised of. Large enough gear ratio and it won't back drive. Safer and more reliable than a brake, but reduces the maximum speed of the bed.

-

Yes you can invrease the idle current too by adjusting the level it drops to.

Motor current idle factor.

https://duet3d.dozuki.com/Wiki/Gcode#Section_M906_Set_motor_currents

Edit: I don't think you can change the idle factor on a per axis basis.

-

There are three different currents involved on Duet 3:

- Current when moving is the current you set using M906

- Standstill current is a fraction of that current, programmed into the drivers. In recent versions of RRF3 you can program that fraction using M917. The default is 0.71. Note, at high M906 current settings, there is a maximum standstill current fraction you can set, in order to limit the standstill current to 4.4A. So up to 4.4A set in M906, you can have any standstill current fraction you like up to 1.0. Above 4.4A, the standstill current will be limited to the appropriate fraction reaching 0.71 at 6.3A current set by M906.

- Idle current percentage, set by the M906 I parameter. Default is 30% but you can increase it to 100%. By default, current is reduced to idle after there has been no motion of any motor for 30 seconds.

HTH David

-

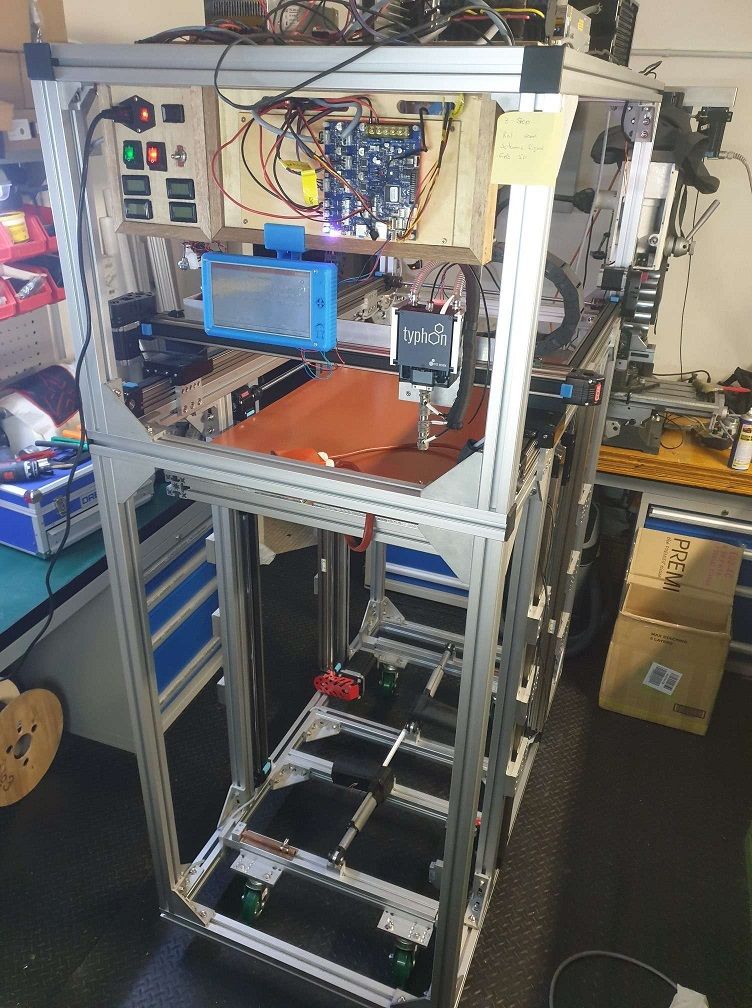

@Marcel Wow, that's quite a machine!

My much smaller printer uses a 30:1 worm gear reducer on the Z axis drive that holds the bed position with or without power, no need for a brake, or any special configuration. You can get worm gear drives to match any size motor, in many different reduction ratios. Here's one for NEMA-34 size motors: https://www.ebay.com/itm/NMRV040-Worm-Gear-Reducer-NEMA34-Ratio-10-15-20-25-30-40-50-100-1-Stepper-Motor/263658655689?hash=item3d6347cfc9

mV79viUbj3dKhMzO3dlvKIA

mV79viUbj3dKhMzO3dlvKIAIf you use a high enough gear ratio, you might be able to lift the bed using NEMA-23 sized motor(s).

My printer uses this one: https://www.ebay.com/itm/Rino-Motorized-Rotary-Table-Stage-CNC-4th-Axis-Sherline-Milling-Engraver-Router/191714031261?epid=711126295&hash=item2ca30bf69d:g:A7UAAOSwPhdVB2f0

-

Thanks to all for the fast replies!

@David

If I understand correctly, I have to increase the idle current M906, not M916 (stand still current). I will try out this with the M906 in the config.@Mrehorstdmd @DocTrucker

I will try this, if that with the M906 doesn't work.Thanks again for your help.

Incidentally, I am Swiss and live with my wife in Malaysia. My English is not good so my wife does the translation. Because of the time difference, it may take a little longer for my answer.here is an image of my 3D Printer. The wiring and finishing work aren't ready now.

-

Hello David

I typed on M906 Z5600 I100 and now the Z-axix holds 50kg after homing or Z-rides.

As soon as I put the order M917 Z100 the bed is falling down, also without weight on the Z-axis.

The Z-axis falls also down when I stop it or do a reset

In the attachment my config,g don't be scared, i am working on it how I have to adjust it. The RepRap firme ware is new for me.Marcel

-

@Marcel said in Problems with the Z axis, falls down:

- Can I increase the holding current?

yes

- Can I set the holding current in the config?

yes

- Can I keep the Z-axis-motors under constant current?

yes

While this can all be done, the unfortunate thing is it does not work 100%. For example, what happens in a power outage or if you activate the emergency stop. Basically anything that stops or resets the microprocessor on the Duet will cause you grief.

Running z through a worm gear is the most practical solution. -

@jens55

The M907 command put a strain on the motors, they all get warm, the NEMA 34 not much but the NEMA 23 on the X- and Y-axis gets hot, even though I specified only the Z motors with the M906 Z5600 I100 without Y and X.

I tend more and more to a Gear Reducer, but I have no clue which gearing I should take 10, 15, 20, 25, 30, 40, 50 or 100:1 -

@Marcel what sort of drive mechanism do you have for the Z Axis ie Screw belt or some other?

-

@Dougal1957

CCM Linear Rail

-

@Marcel i was meaning the drive method but I can see from your pics that is is belt driven so you will need a much higher reduction than you have looking at it it looks to be around 3:1 so it will need to be considerably more but it is out of my skills to calculate that now (been away from that type of industry for well over 40 years).

-

@Marcel the ratio needed depends on the motor torque and the mass being lifted. If your current 3:1 works for lifting, any ratio above that will work, assuming you use the same motors.

Keeping the bed from falling is a different issue. Not all worm gear drives are alike. Worm drives rely on the gear pitch and stiction to prevent back-drive. If the mechanism is subject to vibration, the stiction may go away and the much lower friction may allow back-driving. That shouldn't be a problem in a 3D printer, but since you're lifting a lot of weight, you might want to put a prop under the bed if you're working under it. You have to check the data sheet on the drive unit. In general, it is harder to back-drive higher gear ratios. The 30:1 drive I used is not guaranteed to be impossible to back drive, but under the light load it sees in my printer, it does not back-drive.

The 30:1 drive in my printer allows the bed to move reliably at a top speed of about 15 mm/sec with the motor spinning at about 5 revs per sec. You might not be able to spin a NEMA-34 motor that fast.

-

-

@Marcel There's no way to tell. It is probably not a worm gear box. The worm drive box I used has only two gears in it, a worm on the motor shaft and a disc. The output shaft is 90 degrees off the motor shaft. Any gear box in which the output shaft is parallel to the motor shaft is not a worm drive gearbox or it has two worm gears in it (very unlikely).

This is what is inside the gearbox I used: https://www.youtube.com/watch?v=rjr0L4Dev0g

You have to think about the speed you want to be able to move the Z axis, whether it will drop when power is off, and how much torque you need to lift the weight of the bed. Higher gear ratios allow lower torque motors to lift greater loads, but reduces maximum speed. Higher gear ratios help prevent bed drop. I'd suggest using the highest gear ratio that allows you to drive the Z axis at whatever the minimum acceptable speed is. That will depend on the motor, microstepping, and pps limit of the driver. Steppers lose torque at high rotational speeds like 5 revs per sec.

If you use a worm gearbox, your print's Z axis quality will depend on the quality of the gears in the box. A bad worm will leave repetitive defects in the Z axis of prints with every revolution of the worm gear, but if you're using a large nozzle to print thick layers, that sort of thing will be less of a problem.

-

not sure but would one of these planetary gear box motor work?

-

@Dougal1957 If the gear ratio is high enough, any gear box will stop the bed from dropping. The weight of the bed puts a torque on the gear drive's output shaft (call it load torque). The gearbox converts that to a smaller torque at the motor shaft. Thinking about it the other way, when there's no power, the motor has detent torque- the little bumps you feel when you rotate the motor manually. The gear box multiplies that detent torque to a higher value at the output shaft. If you use a high enough gear ratio, the multiplied detent torque is greater than the load torque, and the load won't move- much. Detents occur at specific rotational positions. If power is lost and the motor is between detents, it may rotate to the next detent, which means it isn't going to completely stop the bed from moving. The high gear ratio means that a fraction of a detent is probably a very small movement at the bed so you may still be able to resume a print after a power failure, depending on the layer thickness.

The exact gear ratio needed will depend on the motor and the weight you're trying to stop from falling, but since detent torque is usually pretty small, it will probably take such a high gear ratio that your maximum Z axis speed will be unacceptably low. 5-10 mm/sec seems OK for lift on retract, but can feel pretty slow when you're jogging the Z axis.

Planetary gearboxes have very odd ratios. Look closely at the data sheet for the exact value, not the "headline" value. A 5:1 planetary gear box will actually have a ratio like 5+2/11:1. You will have to live with the weird whole-step-multiple print layer thicknesses that result - it's just a number, but that sort of thing makes my brain itch. You guys who live in the metric world can understand the feeling by thinking about measuring things in 1/16ths of an inch- it's all just numbers, but ... yuck!

A gearbox represents an opportunity to cause a repetitive print defects with each rotation of each gear. The simple worm gear box has two gears. Everything else has more.

Someone at the makerspace recently built a corexy printer with a belt lifted z axis using one of these motors and the quality of the prints it produces is as good as any I've ever seen. These things have a small worm/disc and a few other gears inside the box.

-

@Marcel said in Problems with the Z axis, falls down:

I typed on M906 Z5600 I100 and now the Z-axix holds 50kg after homing or Z-rides.

As soon as I put the order M917 Z100 the bed is falling down, also without weight on the Z-axis.M917 was only recently implemented for Duet 3 and may not be fully working. I will test it in the RepRapFirmware 3.0 stable release.

The Z-axis falls also down when I stop it or do a reset

That's inevitable without a functioning brake, or a worm drive or similar reducer.

-

I have confirmed that M917 does not function correctly in RRF 3.0. I have already made a fix to the source code, which will be released in RRF 3.01. Meanwhile, do not use M917.

-

@dc42: yes, I will wait until the update arrives.

I will use two worm gear reductors, but I don't know actually which one I should take.

I read a lot in the internet about worm gear reductors and two of them are interessting.

The first is NMRV Worm Gear Reducer Nema 34 30:1 and the second is Rino Motorized Rotary Table Stang 30:1.Here are the details of my motors

Datasheet Nema 34BK50-120.pdf

Datasheet Nema 34HS59-5004S.pdfWith the transmission ratio I am not sure that this is the right one. The Z-axis printerbed has a weight of about 45 kg and in additon the model you print