Should I even try higher than 16x microstepping?

-

I've always found mk8 style extruders suffer from pulsing artefacts certainly at 1/16th microstepping. Going up to 1/32 might help but you'll get lower torque which for an ungeared extruder might mean no filament gets pushed through at all, but easy enough to test. The 3:1 gearing in the titan seems to be about right, retractions are still very fast (50mm/s using 1/16th with interpolation) and no pulsing artefacts unless printing very slow. I have another machine with a printed extruder running off a nema 14 with metal 5:1 planetary gearbox and this prints very nicely too, retractions are fast enough also 50mm/s using 1/16th. My other extruder is a flex3drive with 30:1 gear ratio due to having a worm gear onto the filament drive gear. Here retraction has to be slow 14mm/s at 1/8th microstepping (to reduce the no. of step pulses) and since I'm using PETG I have to retract 2.8mm so each retraction takes a noticeable amount of time, but no pulsing artefacts whatsoever.

-

As soon as my current print is done I'll adjust the extruder microstepping to 32x and run some tests. I'll let you know how it goes.

I've been contemplating a replacement for my print head with its heavy, non-geared direct drive extruder. If I went with, say, an E3D V6 with Titan and a thin pancake stepper I could probably save a considerable amount of weight, which would also help with ringing. Would be great if the gearing improved the surface quality too. My new D-Bot will already have a geared extruder. I can hardly wait to see what prints from it look like.

-

Going up to 1/32 might help but you'll get lower torque which for an ungeared extruder might mean no filament gets pushed through at all, but easy enough to test.

Increasing micro stepping does not reduce torque. Two 1/32 microsteps produce precisely the same amount of torque as one 1/16th microstep. To be more to the point: torque produced by a stepper depends on rotor/field position error, not micro stepping.

-

I am not saying the torque when holding on a full step is any lower, but the torque holding on a microstep is, it stands to reason the coil and rotor teeth are fully aligned on full steps and partially aligned on microsteps so they cannot generate as much holding force.

If you wanted to turn your stepper motor into a winch motor and lift the heaviest object you could, without gearing would you do it with 1/256 or in full steps?

-

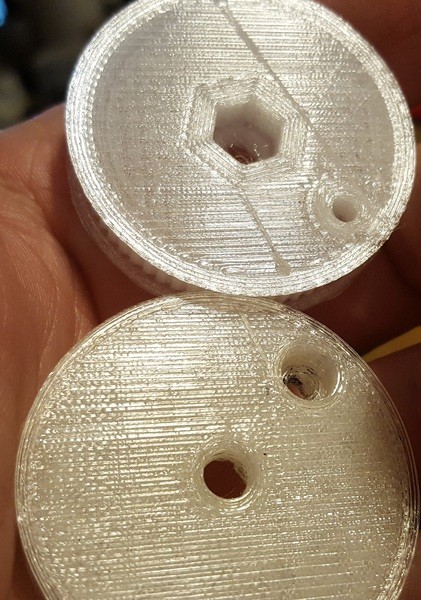

Here's a photo of another copy of this item, this time printed in clear PETG using 1/32 microstepping for my extruder.

The way I had to photograph this in order to show a difference magnifies the appearance of texture. It's actually a little finer than it looks in real life. It's pretty clear looking at it that the extrusion pulsing artifacts are lower in magnitude and with twice the frequency as they were with the 1/16 microstepping.

The two prints I've done so far using 1/32 turned out quite nicely. I think the clear PETG showed some improvement in the quality of the walls that were printed due to more even thickness as a result of less pulsing artifacts.

I'm trying a print now with the extruder using 1/64 microstepping. I'll be interested in seeing how the surfaces look.

The 1/32 microstepping print in clear PETG is the top piece. The 1/16 microstepping print in clear alloy 910 nylon is the bottom piece.

-

That does look much nicer. My point above was that as long as there is enough torque to turn the extruder at this higher microstepping, then there's no reason not to use higher microstepping.

-

I'm not saying that there isn't a difference but there seem to be too many variables. Different parts (or different sides of the same part), different filaments, as well as different micro stepping. For a true comparison, you really ought to change just one thing. i.e. to evaluate the effect of micro stepping, change only the micro stepping but keep everything else the same. Please don't take this the wrong way, I'm not trying to criticise. Ian

-

How about going the other way, can you set 1/8th and try again?

-

For a direct drive extruder with about 100 steps/mm at 16x microstepping, you could even increase microstepping to 256x.

-

I'm running my direct drive extruders with 200 steps/mm at 128x with good results. Actually everything on the printer is running at 128x with good results.

-

I changed it to 64x, and the surface quality turned yet more even and the artifacts smaller and closer together than they had been at 32x. The quality difference certainly diminishes though. I can hardly wait to use my 4:1 belted extruders that I just built for my D-bot.

One more thing I noticed is that the walls printed with clear PETG became more transparent. I think the reason is that with the pulsing artifacts reduced, the surface of these walls is more even, so the light going through them is less scattered.

I may try 128x or higher this evening.

-

I noticed the largest difference going from 1.8 deg/step motors to 0.9 deg/step. Toss in 128x or 256x stepping and it's even better.

-

As an aside the variation in translucency that you see in PETG etc is being used in a really cool way:

https://plus.google.com/s/%23VelocityPainting/top

Picture from Mark Wheadon (https://plus.google.com/+MarkWheadon/posts/9xdtMh3en7S) -

Wow Tony. Thanks for sharing the link. - Now THAT is clever.

-

Holy crap that's awesome! I love how he's getting those faces on there.

This is kind of wierd but I've never printed a vase yet. I should try that, and then see if I can get that velocity painting to work. That's just too cool.